Unmanned ship with monitoring function

An unmanned ship, functional technology, applied in the direction of water testing, ship construction, ship parts, etc., can solve the problems of difficult depth adjustment, inaccurate detection effect, etc., to achieve the effect of depth adjustment, depth control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

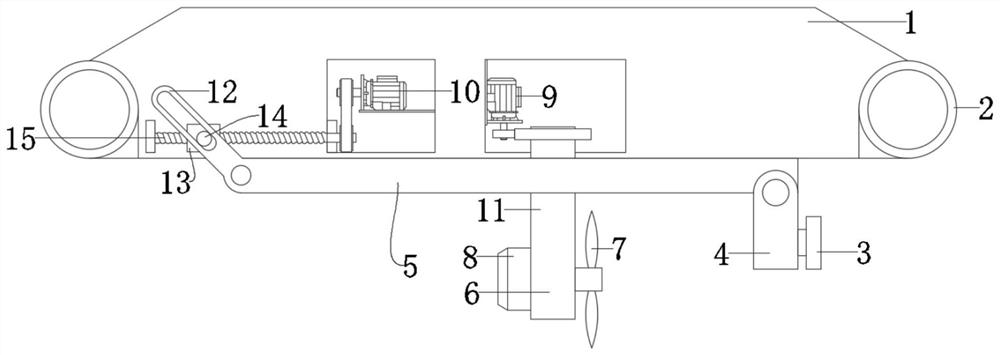

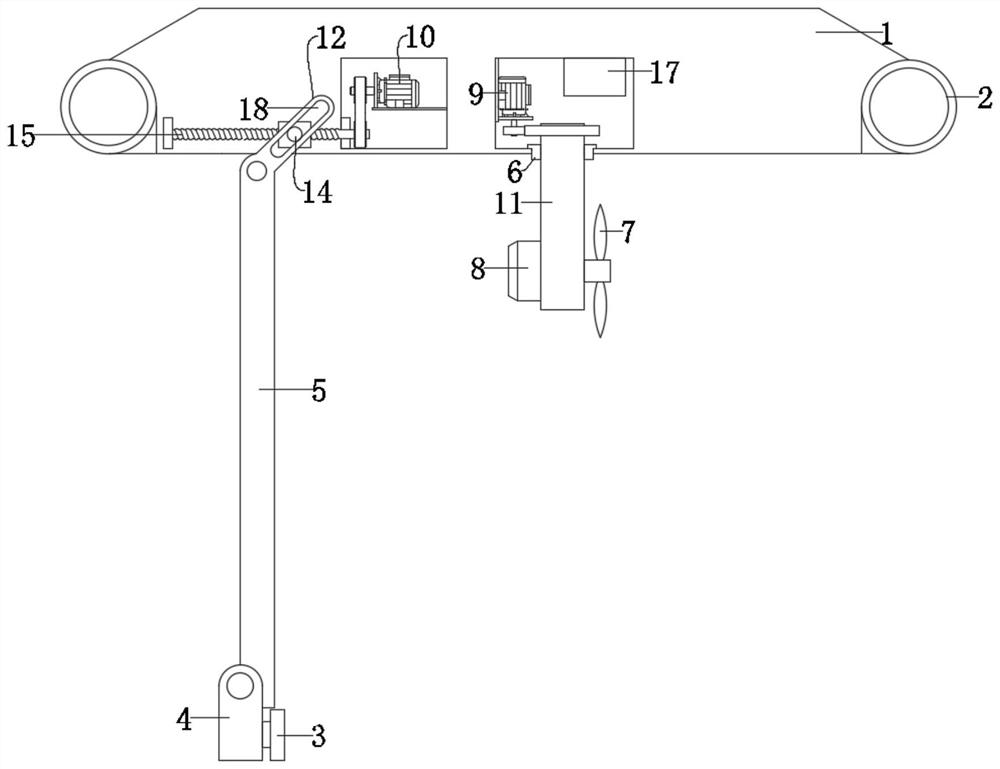

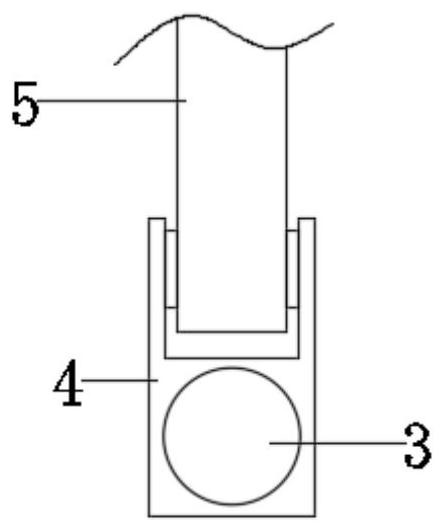

[0023] see Figure 1-3 , an unmanned ship with a monitoring function, including a hull 1 and a detection probe 3, an adjustment assembly is installed on the hull 1, and the detection probe 3 is installed on the adjustment assembly; the detection is further realized through the adjustment assembly The depth adjustment of the probe 3 improves the actual use effect of the device; and a driving assembly is installed on the hull 1, and the movement of the hull 1 is realized through the driving assembly, thereby making the movement of the hull 1 on the water surface; in the hull 1 A control module 17 is fixedly connected, and the control module 17 and the drive component are electrically connected to the control module 17, and the movement of the control module 17 and the drive component is further realized through the control module 17.

[0024] Specifically, the adjustment assembly includes an adjustment frame 5, a turret 4, a drive rod 12 and a power unit, the adjustment frame 5 ...

Embodiment 2

[0030] In this embodiment, the following improvements are made on the basis of the above embodiments. Specifically, the included angle between the driving rod 12 and the adjusting rod is 120 degrees to further improve the actual use effect of the device.

[0031] The working principle of the present invention is: during use of the device, the axial movement of the drive block 13 is realized by the rotation of the drive screw 15; the limit block 14 is fixedly connected to the limit block 14, and the limit block 12 is set Groove 18, the limit block 14 is slidingly arranged in the limit groove 18, and the sliding of the drive block 13 further makes the limit block 14 drive the drive rod 12 to rotate, and then drives the rotation of the adjustment frame 5. The bottom is in a free drooping state; according to the rotation positions of different adjustment frames 5, the depth adjustment of the adjustment frame 5 is effectively realized, and then the depth regulation of the detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com