Automatic crust breaking device for top floating slags of marsh gas fermentation tank

A biogas fermentation and automatic shell breaking technology, applied in bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, biochemical cleaning device, etc. and other problems, to achieve the effect of saving costs and increasing the output of biogas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

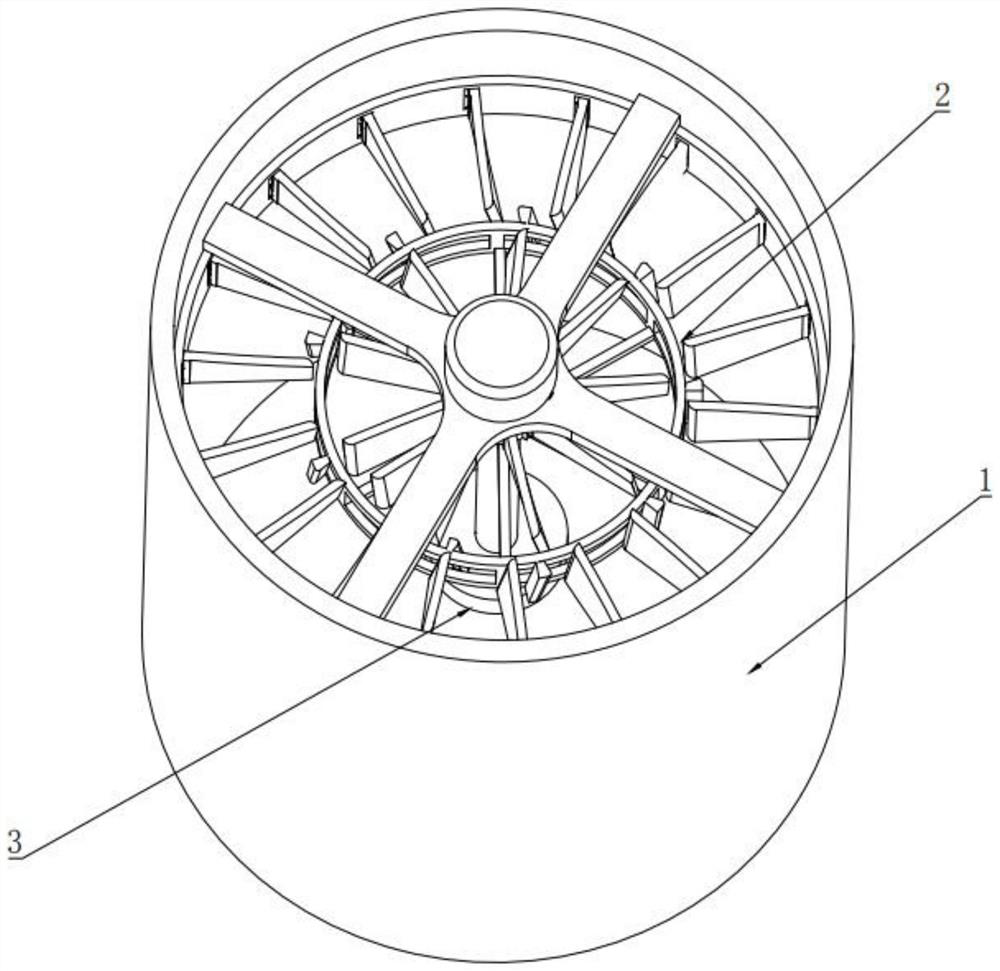

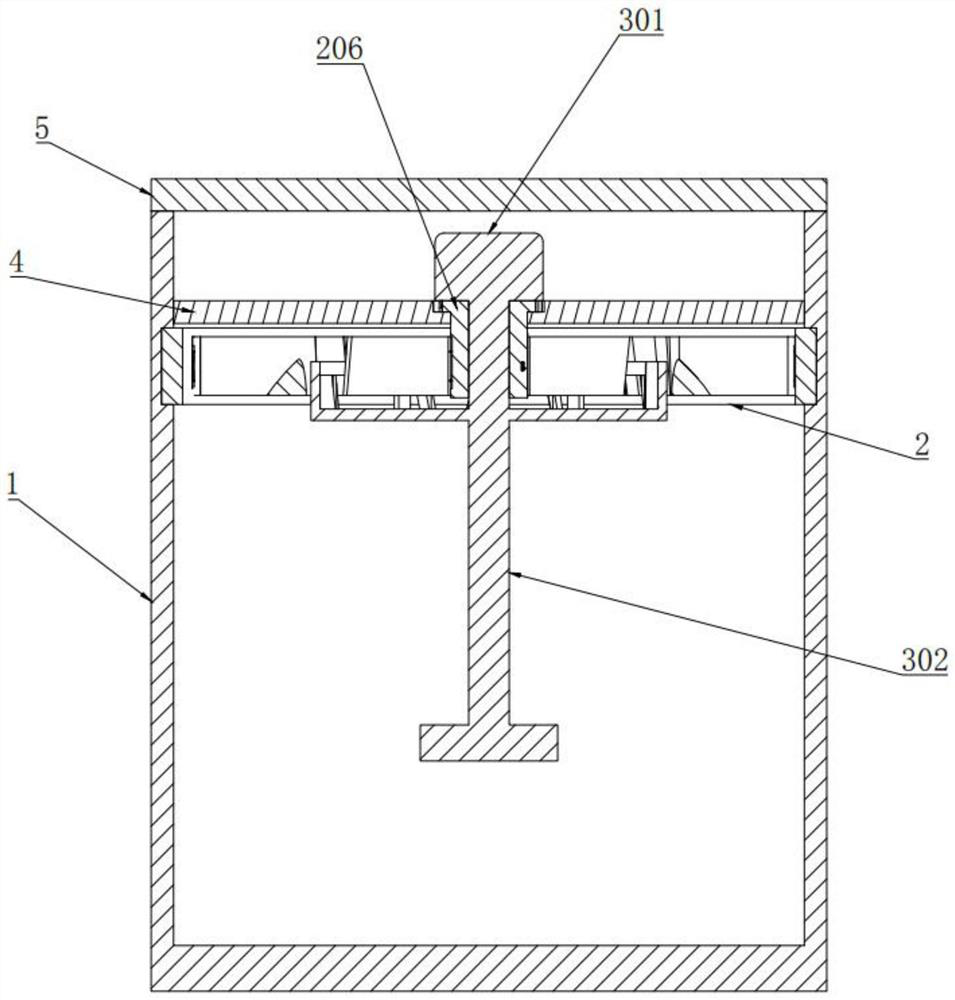

[0023] The present invention relates to an automatic shell breaking device for scum at the top of a biogas fermentation tank, which includes a biogas tank main body 1, a shell breaking mechanism 2, and a stirring mechanism 3, wherein: the biogas tank main body 1 is a cylindrical structure, and the biogas tank main body 1. A load-bearing bar 4 is fixedly installed on the upper part. The upper end of the biogas tank main body 1 is provided with an upper cover 5. A drive motor 301 is installed on the load-bearing bar 4. A stirring shaft 302 is connected below the drive motor 301. The load-bearing bar 4 below is provided with broken shell mechanism 2.

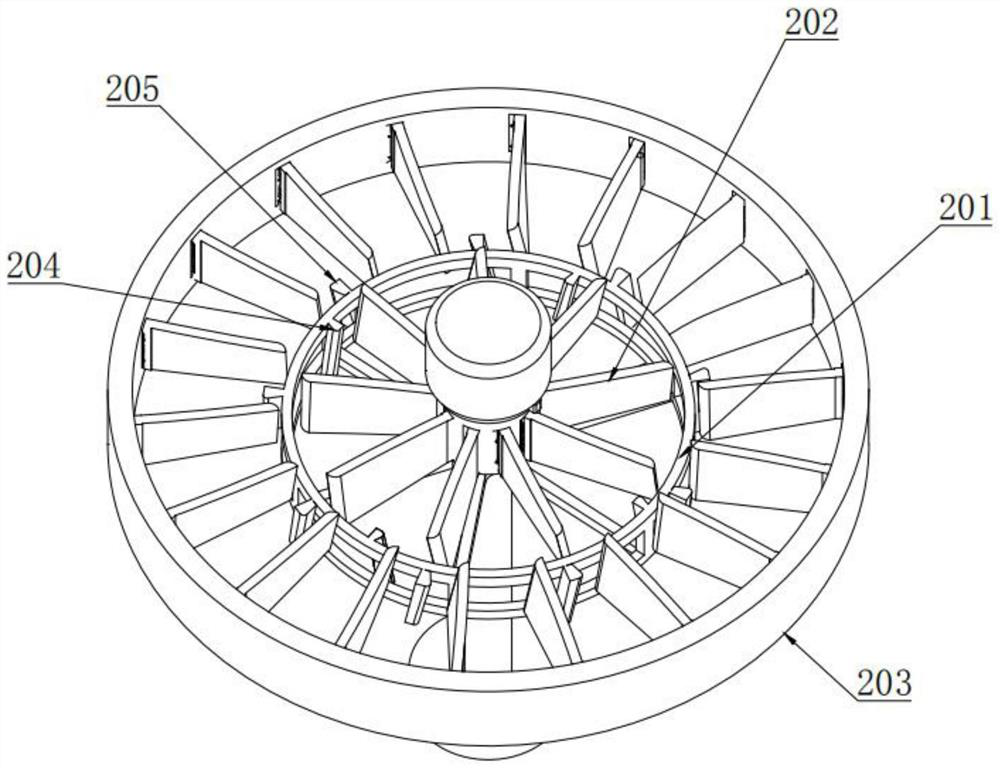

[0024] Specifically, the cracking mechanism 2 includes a driving mechanism 201, an inner cracking device 202 and an outer cracking device 203, wherein the driving mechanism 201 is in the shape of a circular disk, and the driving mechanism 201 is fixedly connected to the stirring shaft 302, The inner ring of the driving mechanism 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com