Electroplating device suitable for preparing small-area radioactive source

An electroplating device and radioactive source technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of cathode approach, deviation of the active area of the radioactive source from the center, and difficulty in peeling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained in detail below in conjunction with the accompanying drawings.

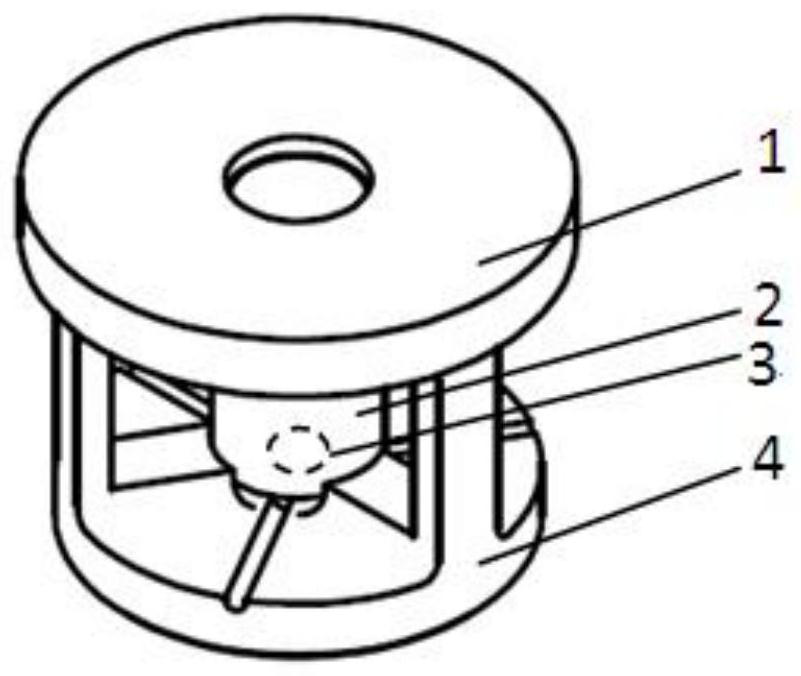

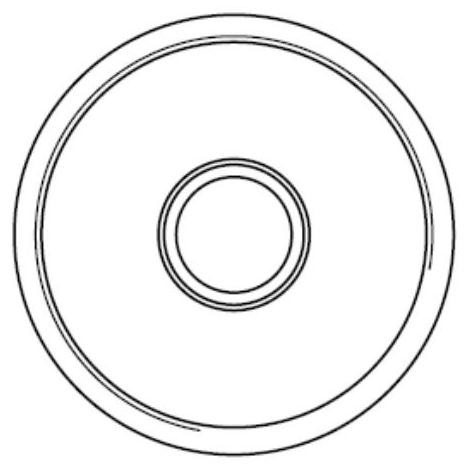

[0022] Such as Figure 1 to Figure 5 As shown, the electroplating device suitable for the preparation of small-area radioactive sources in the present invention includes a cover 1, a tank body 2, a gasket 3 and an electroplating tank base 4. During assembly, the gasket and the tank body are placed on the electroplating tank base in sequence, and then the cover 1 is connected with the base 4 of the electroplating tank through threads.

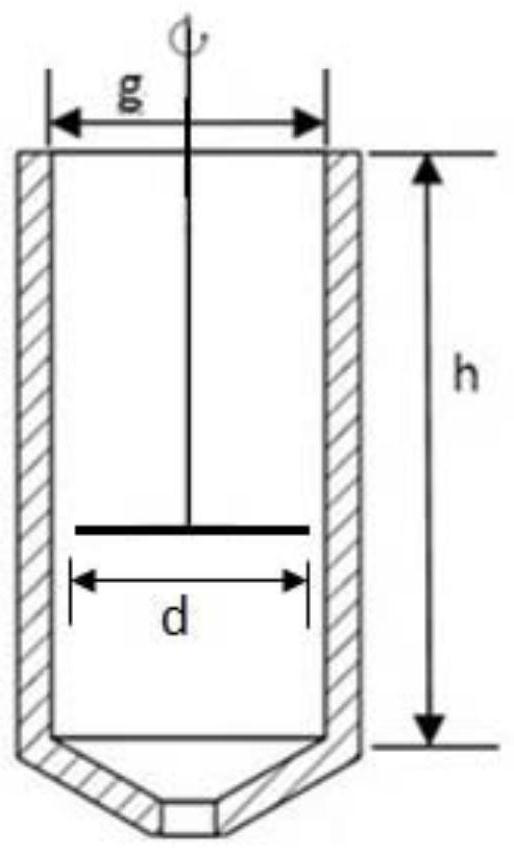

[0023] Described tank body 2 adopts the vertical cavity structure that the bottom gradually narrows, as image 3 As shown, the tank body 2 includes a cylindrical cavity at the upper end and a conical cavity at the lower end, so that the anode can adjust the pole spacing at any height in the cylindrical cavity area, that is, when the diameter d of the anode is slightly smaller than the diameter g of the inner cavity of the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com