Lock hook with simple structure and high reliability

A simple and reliable technology, applied in the field of lock hooks, can solve the problems of complex structure, large lock hook device, time-consuming and labor-intensive assembly, etc., achieving a simple and compact structure, high degree of automation, and solving the problem of time-consuming and labor-intensive assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

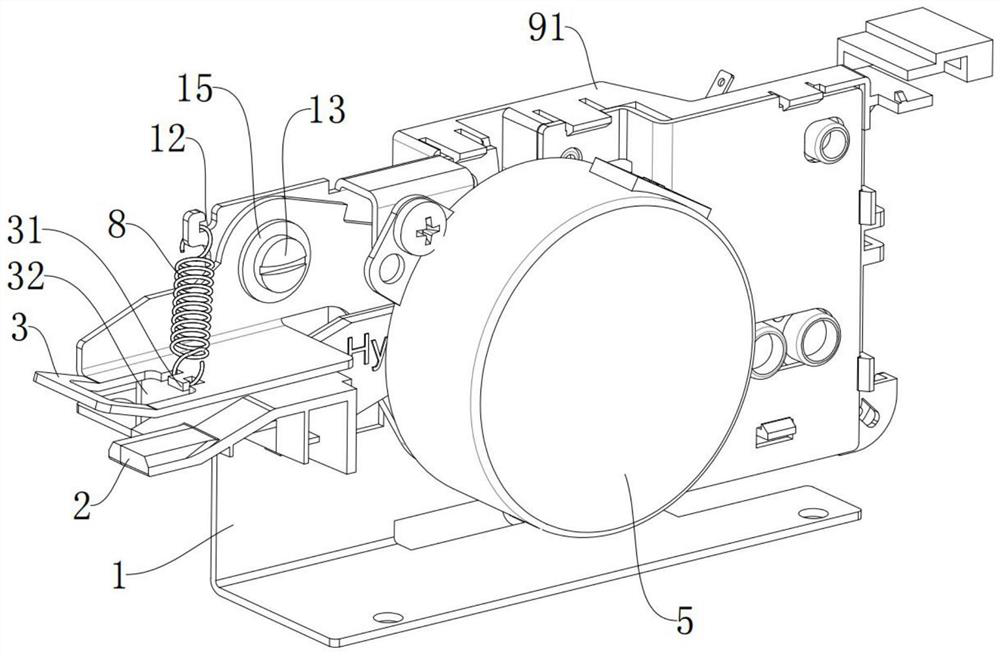

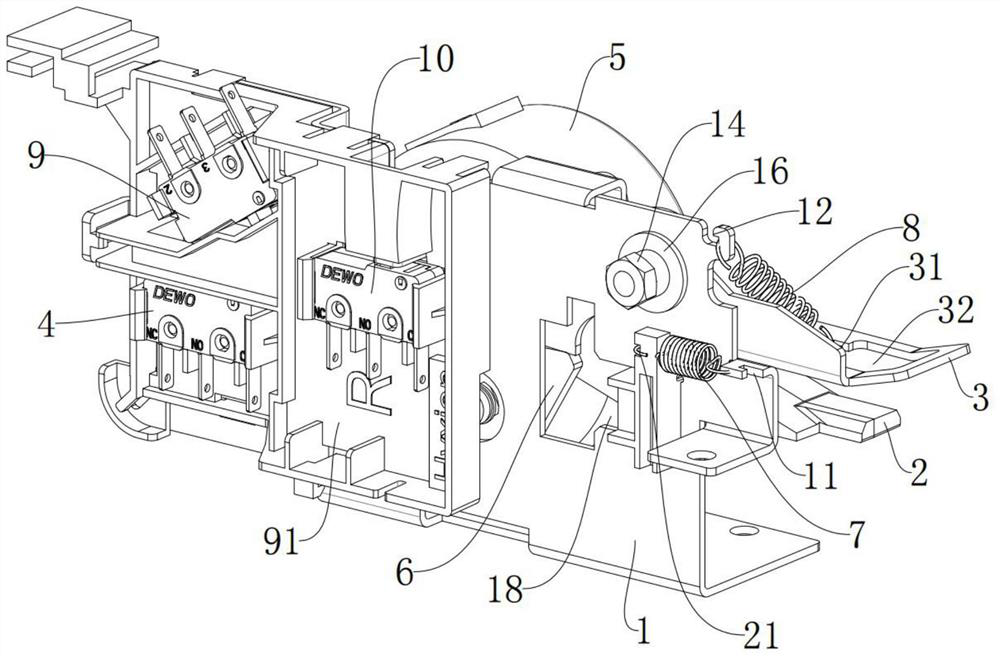

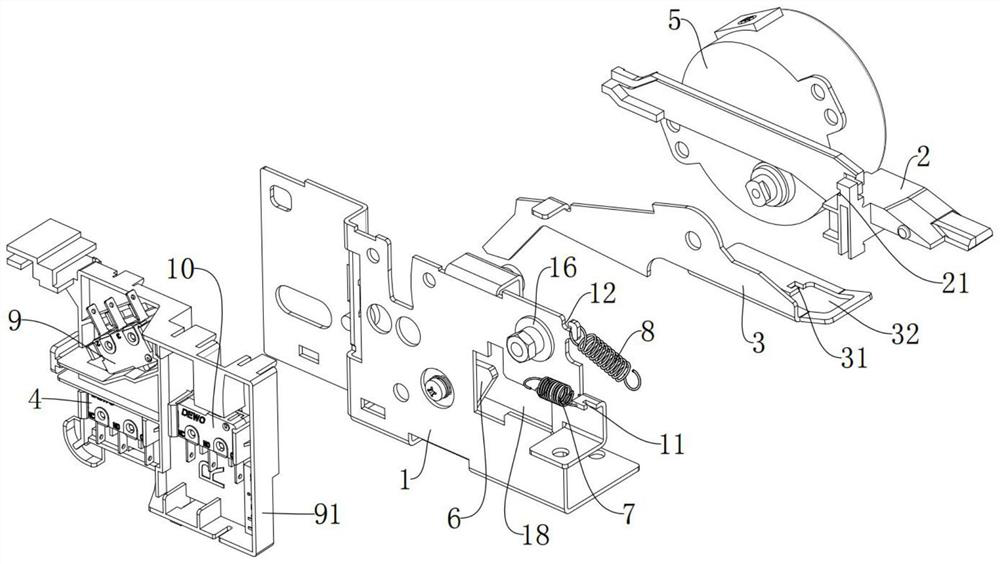

[0021] Please refer to Figure 1-Figure 3 , the present embodiment provides a lock hook with simple structure and high reliability, which includes a lock hook base 1, a lock hook induction plate 2 arranged on the lock hook base 1 for sliding connection, and a lock whose middle part is hinged to the lock hook base 1. The hook piece 3, the first sensor 4, the motor 5, the induction plate extension spring 7, the hook extension spring 8 respectively arranged on the hook seat 1, and the cam 6 which is arranged on the hook seat 1 and connected with the motor 5 in transmission ; One end of the induction plate extension spring 7 is relatively fixed with the lock hook seat 1 and its other end is relatively fixed with the lock hook induction sheet 2; one end of the lock hook extension spring 8 is relatively fixed with the lock hook seat 1 and its other end Relatively fixed with the lock hook sheet 3, the first sensor 4 is used to detect whether the distance that the lock hook induction ...

Embodiment 2

[0029] Please refer to Figure 1-Figure 3 , the present embodiment also provides another lock hook with simple structure and high reliability, which also includes a second sensor 9 and a third sensor 10 respectively relatively fixed on the lock hook seat 1, and the rest of the structure is the same as that of the first embodiment, No longer repeat.

[0030]Specifically, the second sensor 9 is used to detect whether the lock hook plate 3 is locked and locked in place after the cam 6 is driven to move around the axis, and the third sensor 10 is used to detect whether the lock hook plate 3 is pulled by the lock hook extension spring 8 Return to the position where the door can be opened. Specifically, when the lock hook piece 3 is driven by the cam 6 to move around the axis, it will be able to clamp and lock the external lock block. At this time, the second sensor 9 will sense the lock hook piece 3 and transmit a signal to the system. , the system can ensure that the locking act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com