Absolute elevation level, absolute elevation level system and use method of system

A technology of absolute elevation and level, which is applied in the field of measurement, can solve problems such as heavy workload, poor accuracy, and absolute elevation cannot be known immediately, and achieve the effect of good accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

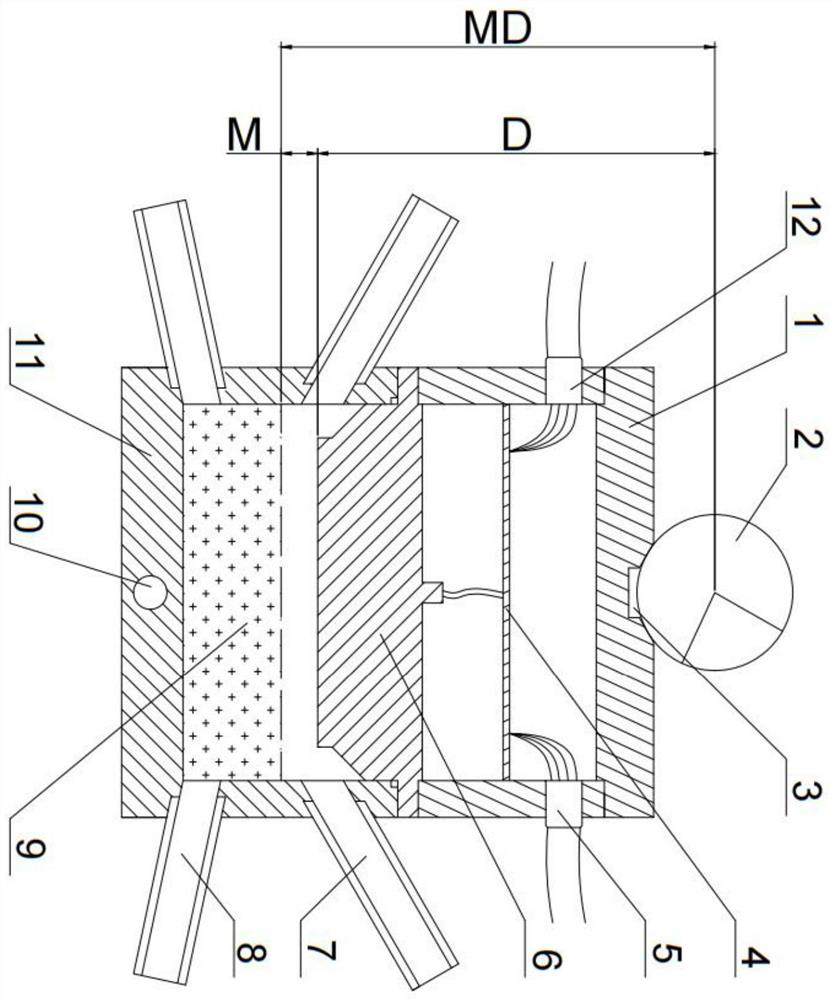

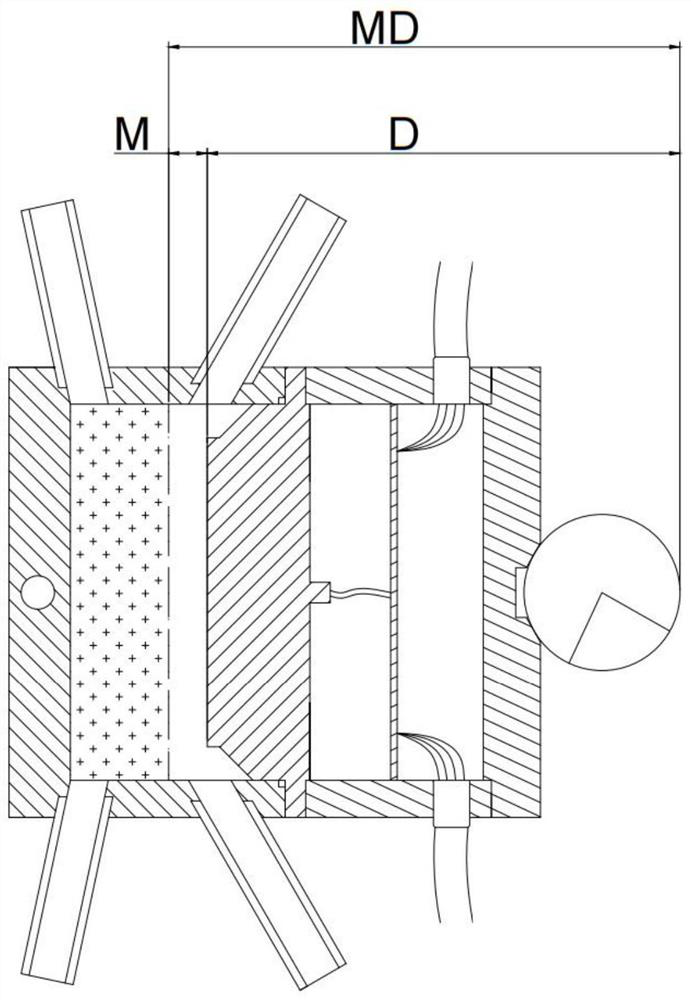

[0029] Absolute height level (such as figure 1 ), including a housing and a liquid level sensing sensor 6, the liquid level sensing sensor 6 is arranged in the housing, and the housing is divided into an upper housing 1 and a lower housing 11, the lower housing 11 is used to place the liquid 9; the upper housing The upper surface of the body 1 is provided with a reference seat 3 for placing the target ball 2;

[0030] In this embodiment, the reference seat 3 is a tapered ball seat, where various standard measurement target balls 2 can be placed on the reference seat 3 .

[0031] In this embodiment, the air pipe interface 7 is arranged at the upper end of the lower casing 11 , and the water pipe interface 8 is arranged at the lower end of the lower casing 11 .

[0032] Wherein, there are two gas pipe interfaces 7, which are respectively arranged on both sides of the lower housing 11;

[0033] In this embodiment, the lower housing 11 is provided with a temperature sensor insta...

Embodiment 2

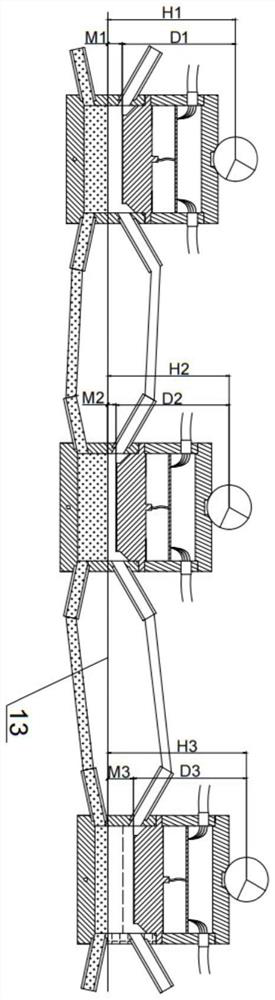

[0035] In this embodiment, the absolute elevation level provided by multiple embodiments 1 is placed at the monitoring point and connected in series to form an absolute elevation level system (such as figure 2 ), the absolute elevation of each monitoring point can be obtained after the liquid level reaches a stable level. Wherein, the air pipe interface 7 and the water pipe interface 8 on one absolute height level are respectively connected to the air pipe interface 7 and the water pipe interface 8 on the other absolute elevation level through the gas connecting pipe and the liquid 9 connecting air pipe.

Embodiment 3

[0037] The using method of the absolute height level system, using the absolute height level system provided by embodiment 2, the method comprises the following steps:

[0038] S10, calibrating each absolute height level;

[0039] The method for calibrating each absolute height level is as follows:

[0040] S11, leveling the absolute height level;

[0041] S12. Add liquid 9 within the range of the liquid level sensing sensor 6 into the lower housing 11, and accurately calibrate the distance between the liquid level in the lower housing 11 and the center of the target ball 2 located on the outer reference surface of the upper housing 1. MD, obtain the height M of the liquid level in the lower casing 11 by the liquid level sensing sensor 6 simultaneously, the distance D=MD-M (such as figure 1 );

[0042] or

[0043] Accurately calibrate the distance MD between the liquid level in the lower casing 11 and the dome of the target ball 2 located on the outer reference surface of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap