Installation, flow measurement and maintenance method of open channel ultrasonic flowmeter

An ultrasonic flowmeter and open channel technology, applied in the measurement of flow/mass flow, measurement device, volume measurement, etc., can solve the problems of wasting manpower and material resources, difficulty in replacement and maintenance, and occupation, and simplify the power supply system and reduce maintenance. The effect of construction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

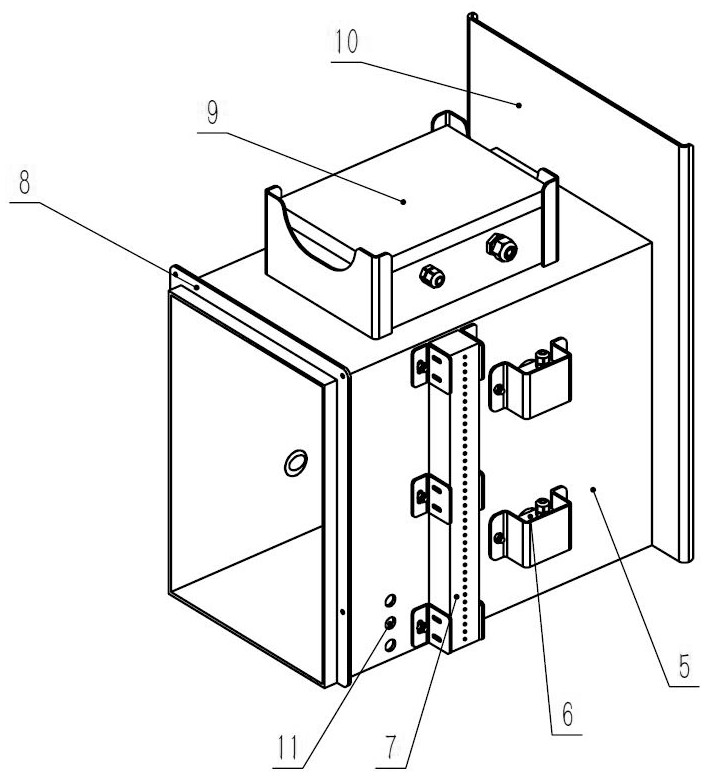

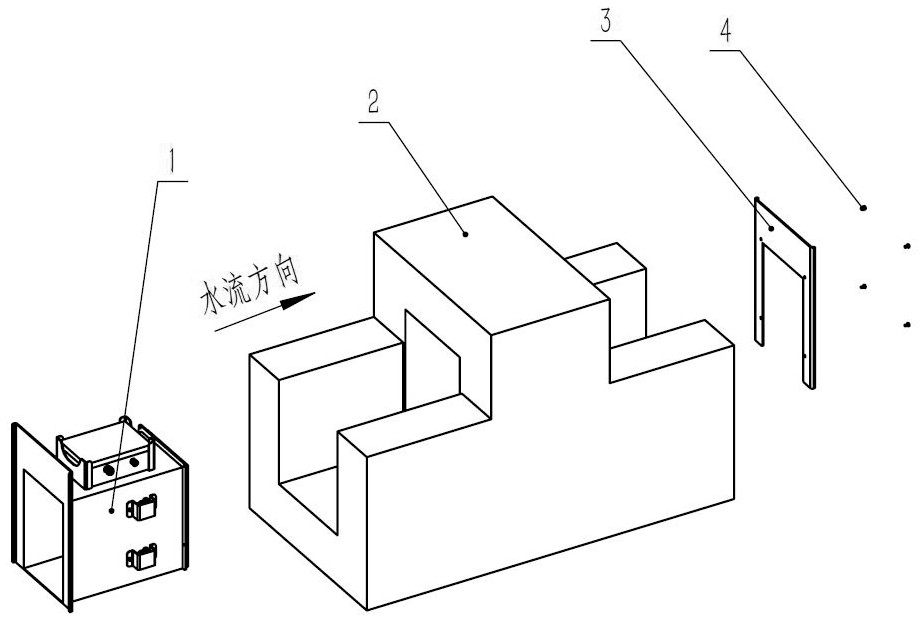

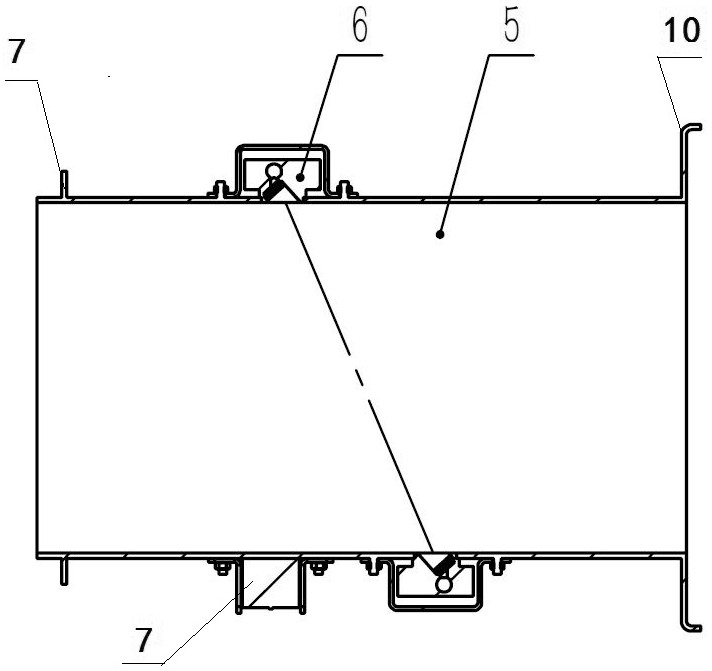

[0046] Embodiment 1 A more specific installation method: Push the open channel ultrasonic flowmeter 1 from the upstream channel 13 into the prefabricated culvert 2, and use bolts 4 to install the rear sealing plate 3 on the connecting flange 8, pass the front sealing plate 10 and the rear sealing plate 3 clamp the open channel ultrasonic flowmeter 1 on the culvert 2, and the open channel ultrasonic flowmeter 1 is positioned; after the transducer 6 is installed, the probe of the transducer 6 and the inner wall surface of the culvert box 5 are plane; The plate 3 is connected to the culvert box 5 through the connecting flange 8, and the liquid level gauge 7 is installed on the culvert box 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com