Uniform mixing production process control method

A production process control and mixing technology, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve the problems of large error, scrap, low quality of mixture, etc. The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of mixing production process control method of the present embodiment, its steps are:

[0034] Step 1. Obtain the amount of slotting a, the amount of material in the initial bin m, the amount of material at the end of the cycle n, the amount of batching c, the batching rate r, and the theoretical batching rate r within an adjustment period t during the mixing process 0 :

[0035] Among them, the amount of slotting a is measured by the slotting scale at the feed inlet of the storage bin; the initial amount of material in the bin m and the amount of material at the end of the cycle n are measured by the hopper scale; the amount of ingredients c is measured by the quantitative feeding equipment ; Batching rate r=batching amount c / period t; The theoretical batching rate r 0 It is the planned total amount / planned batching time.

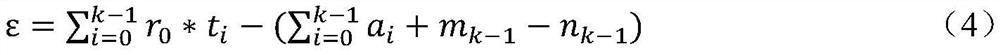

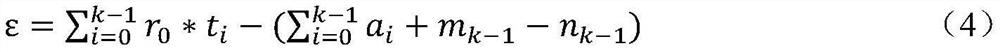

[0036] Step 2. Determine the relative error of the dosing equipment and the hopper scale, and calculate the absolute error within the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com