Patents

Literature

32results about How to "Less susceptible to vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

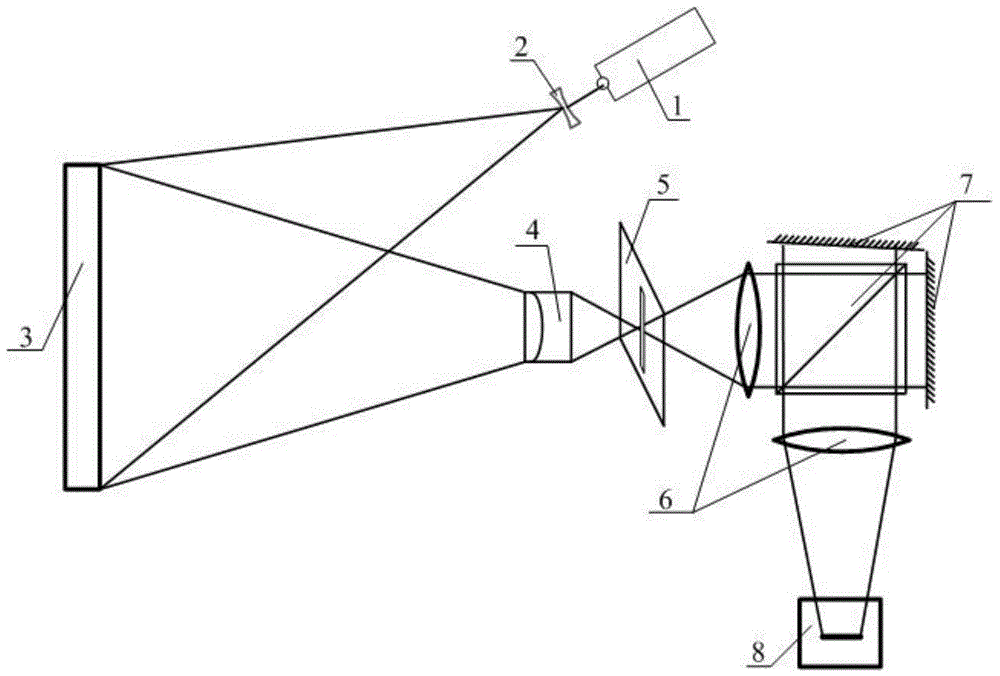

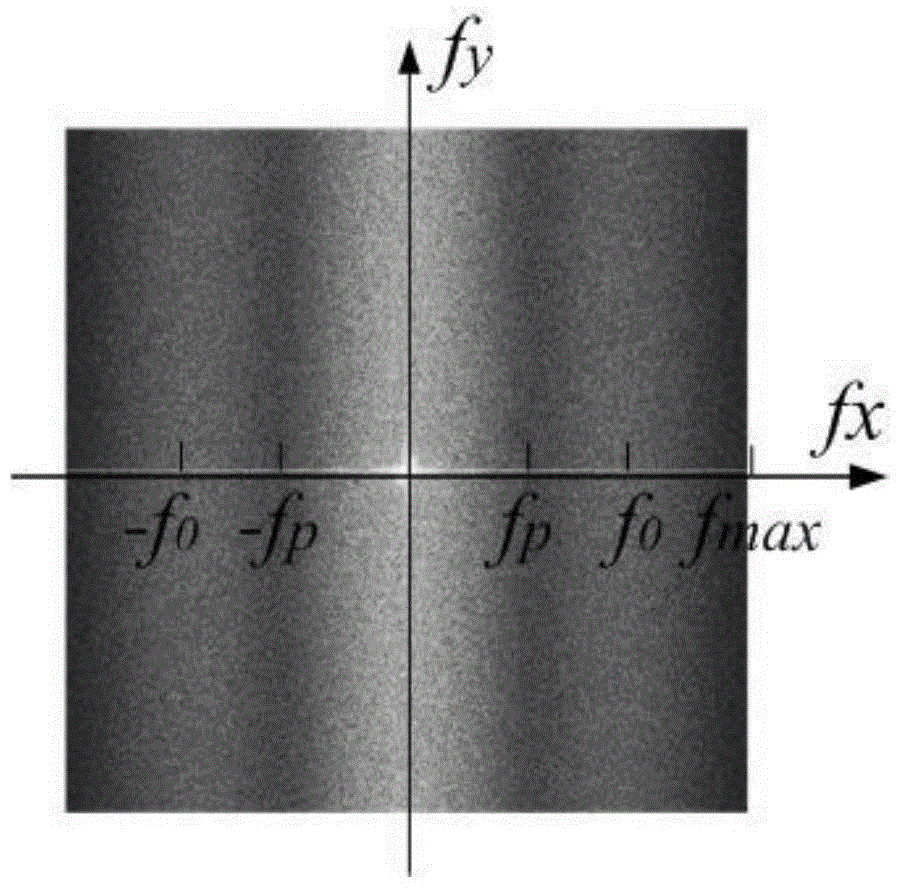

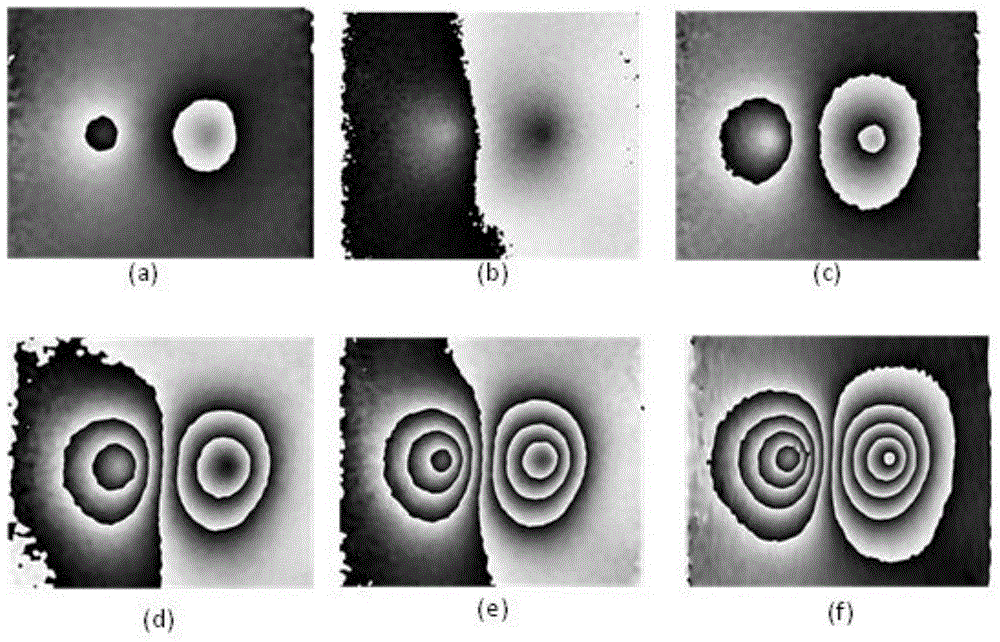

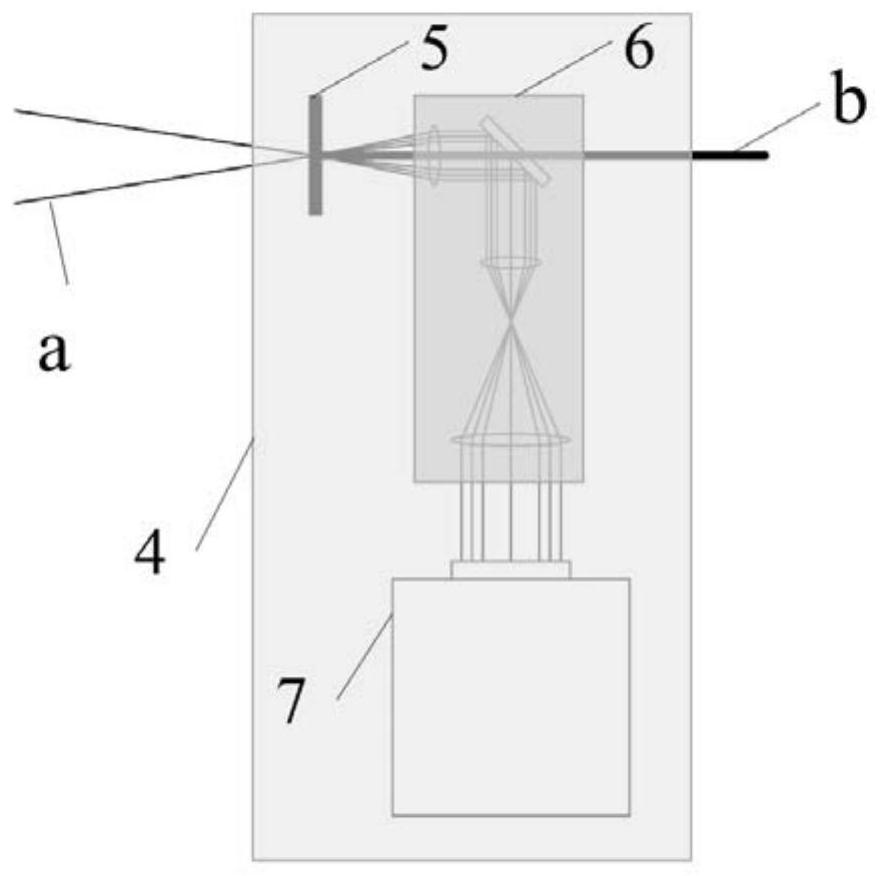

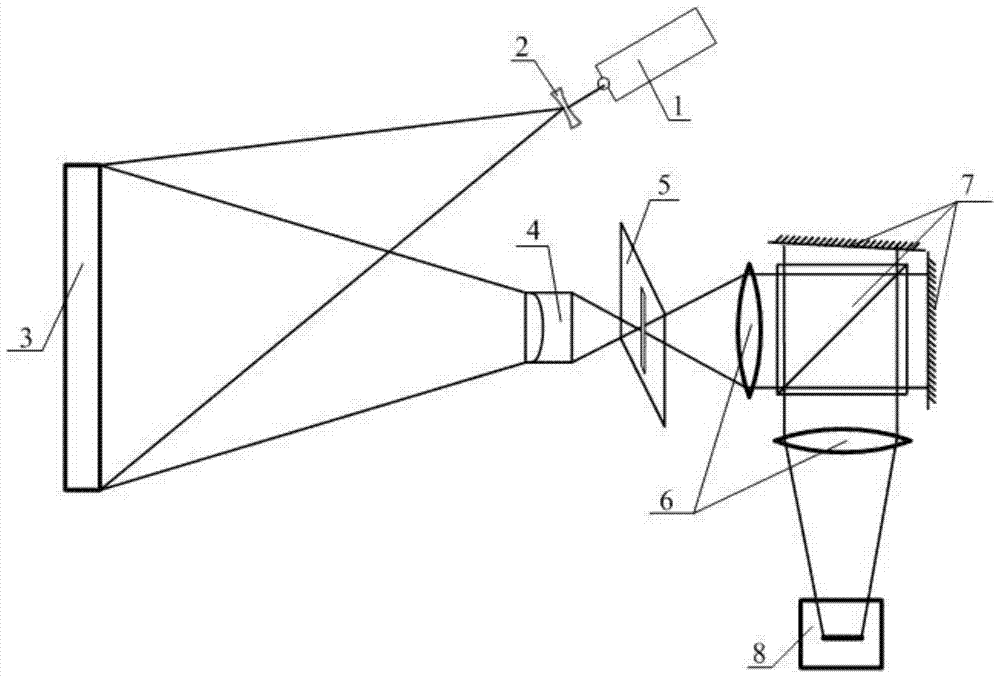

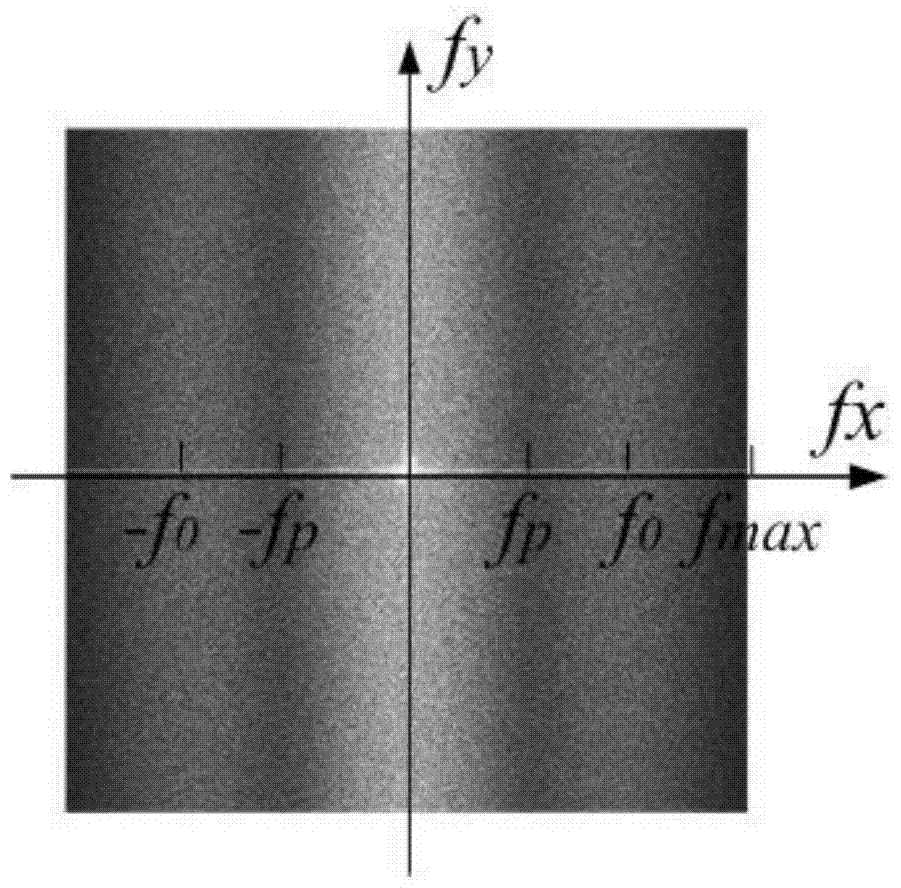

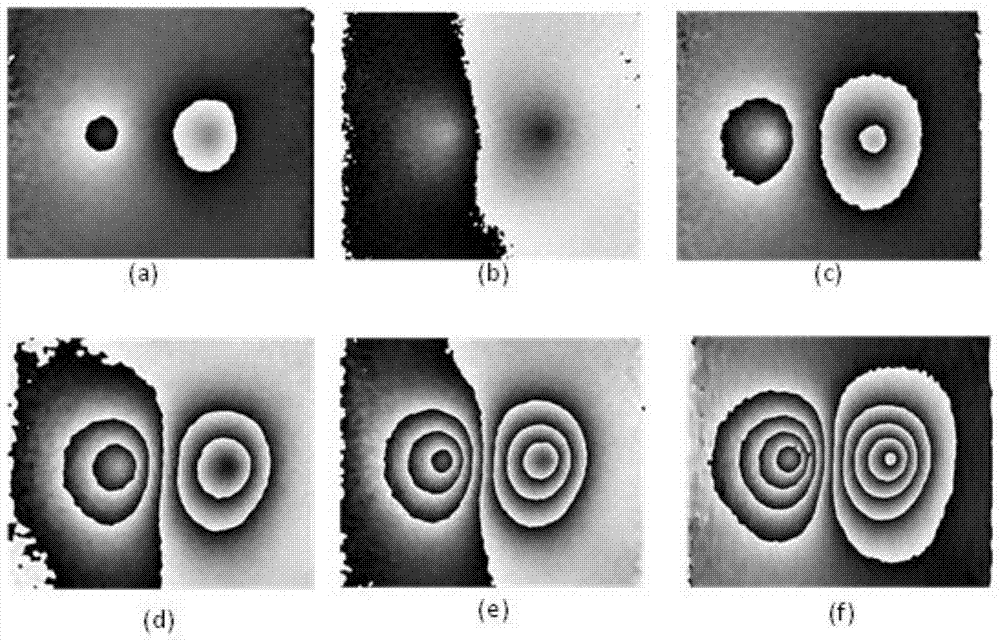

Single-slit spatial carrier shearing speckle interferometry measuring system and measuring method

ActiveCN104482875AQuick solveFast dynamic real-time measurementOptically investigating flaws/contaminationUsing optical meansCcd cameraImaging lens

The invention discloses a single-slit spatial carrier shearing speckle interferometry measuring system and a measuring method. The measuring system and the measuring method are characterized in that laser shot by a laser device passes through a beam expander and then irradiate a measured object in the form of diffusion light, diffuse reflection light on the surface of the measured object sequentially passes through an imaging lens, a slit diaphragm, a 4f system and a Michelson type device to be projected onto a target surface of an CCD camera. The measuring system and the measuring method can carry out nondestructive, full-field, rapid and dynamic measurement for the defects and stress deformation of the surface of the measured object and is convenient for field measurement.

Owner:HEFEI UNIV OF TECH

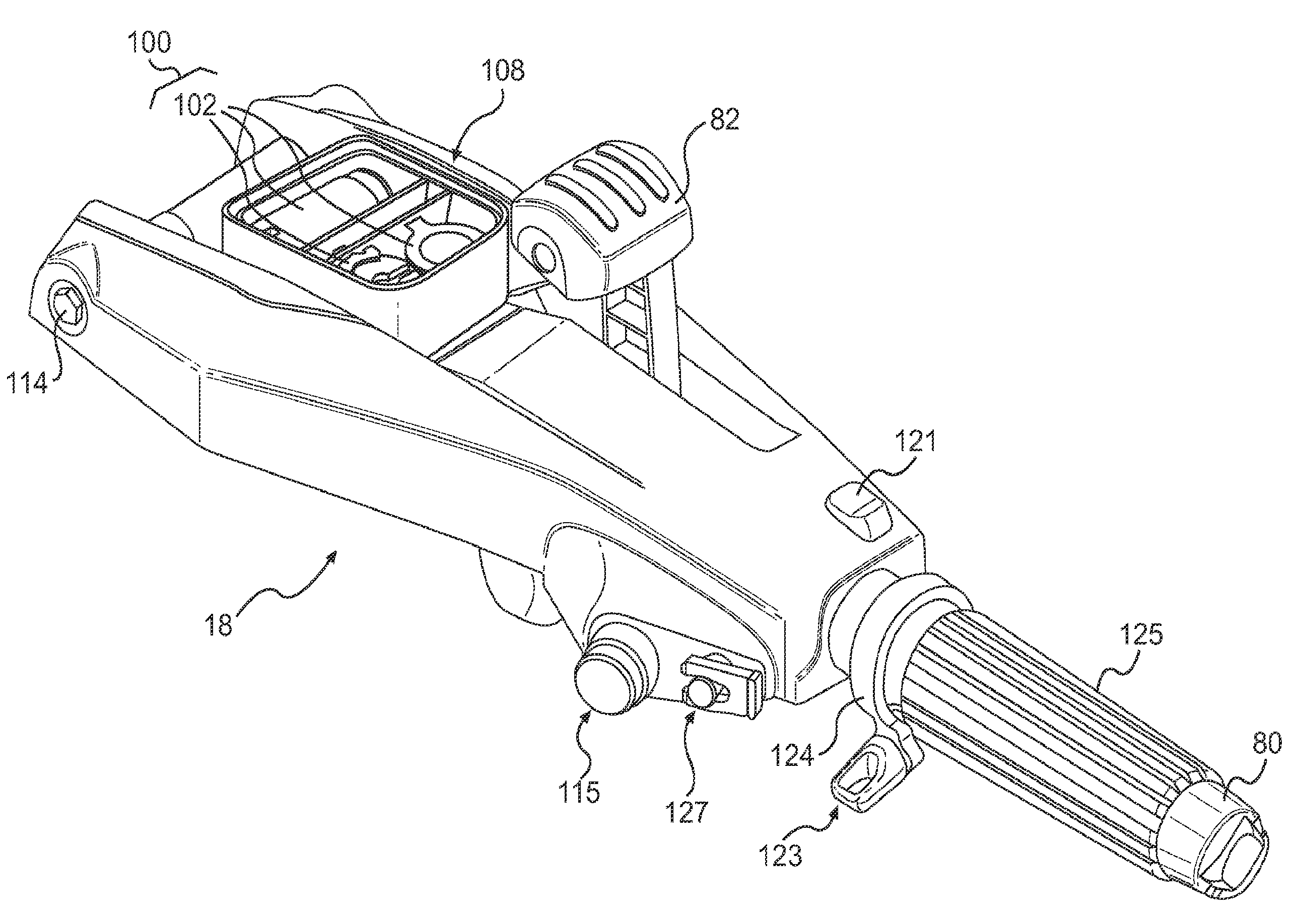

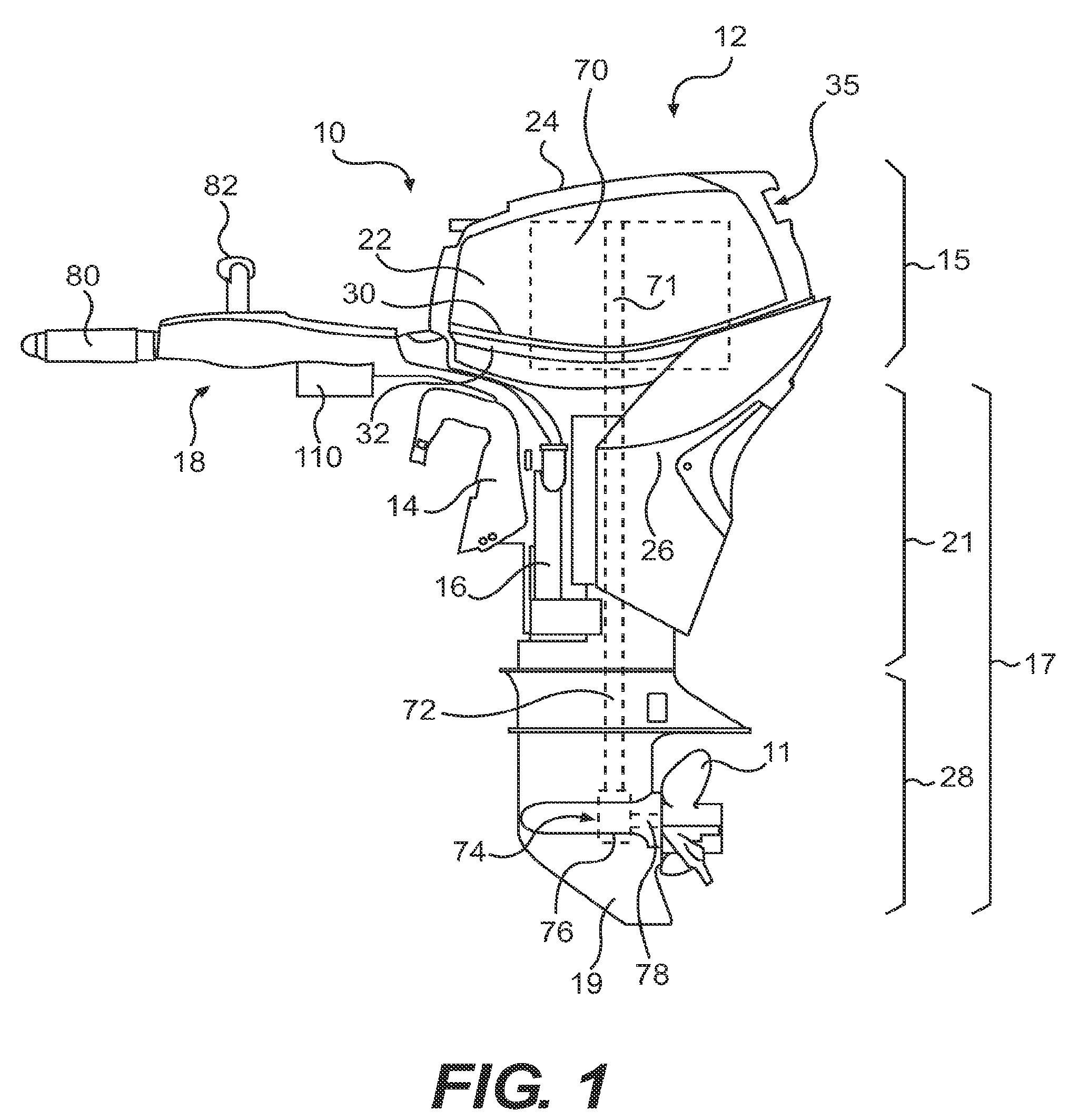

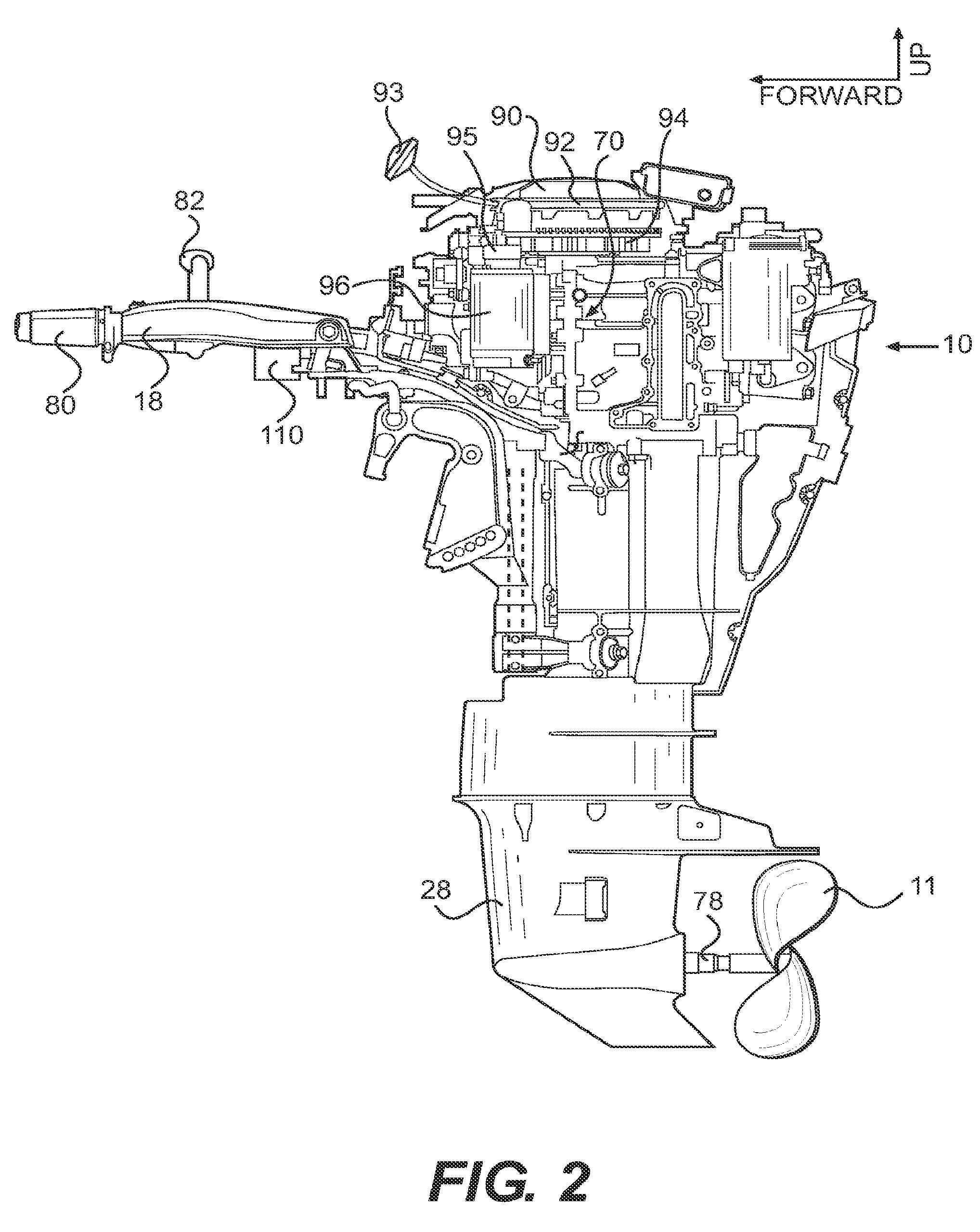

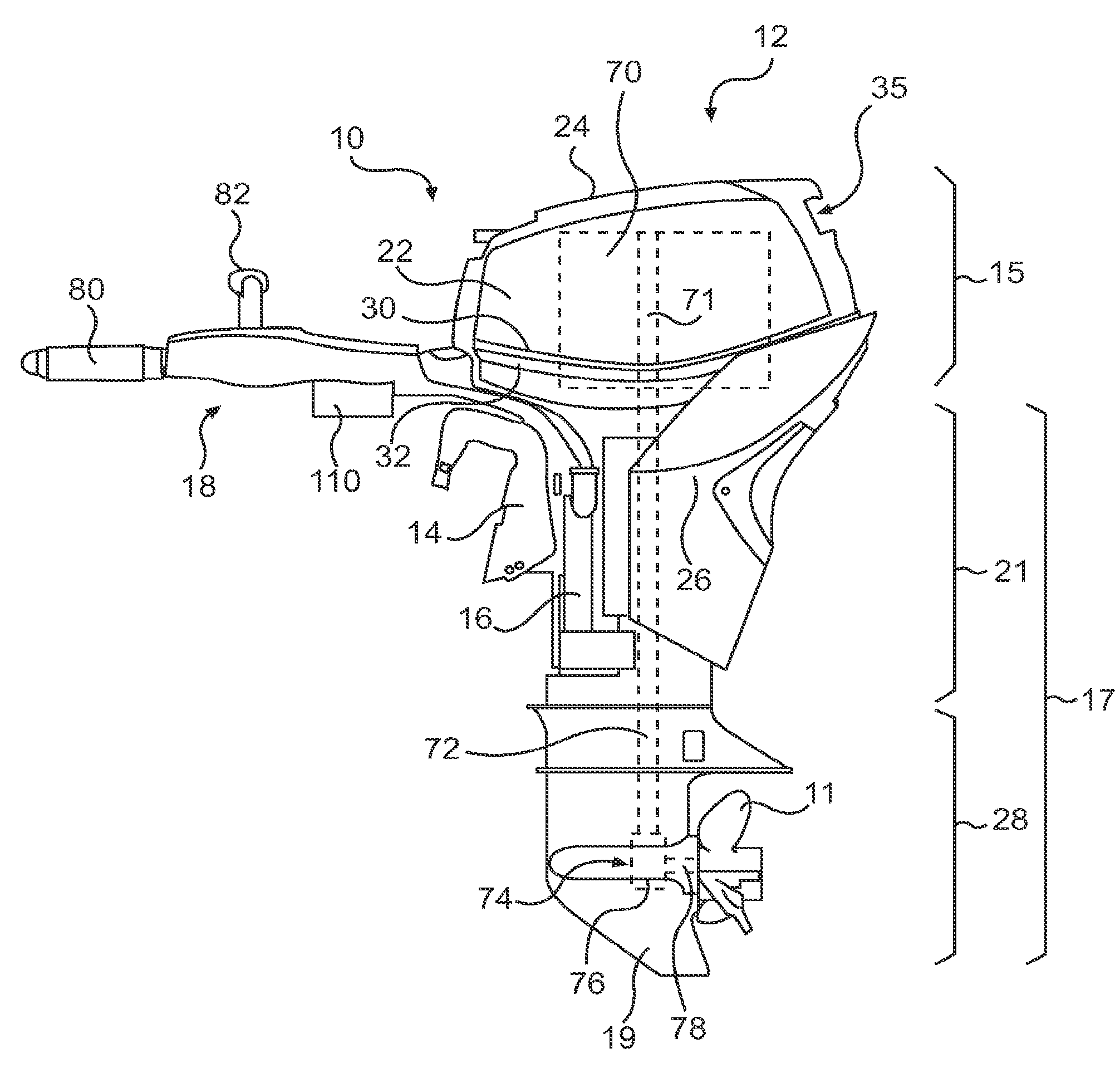

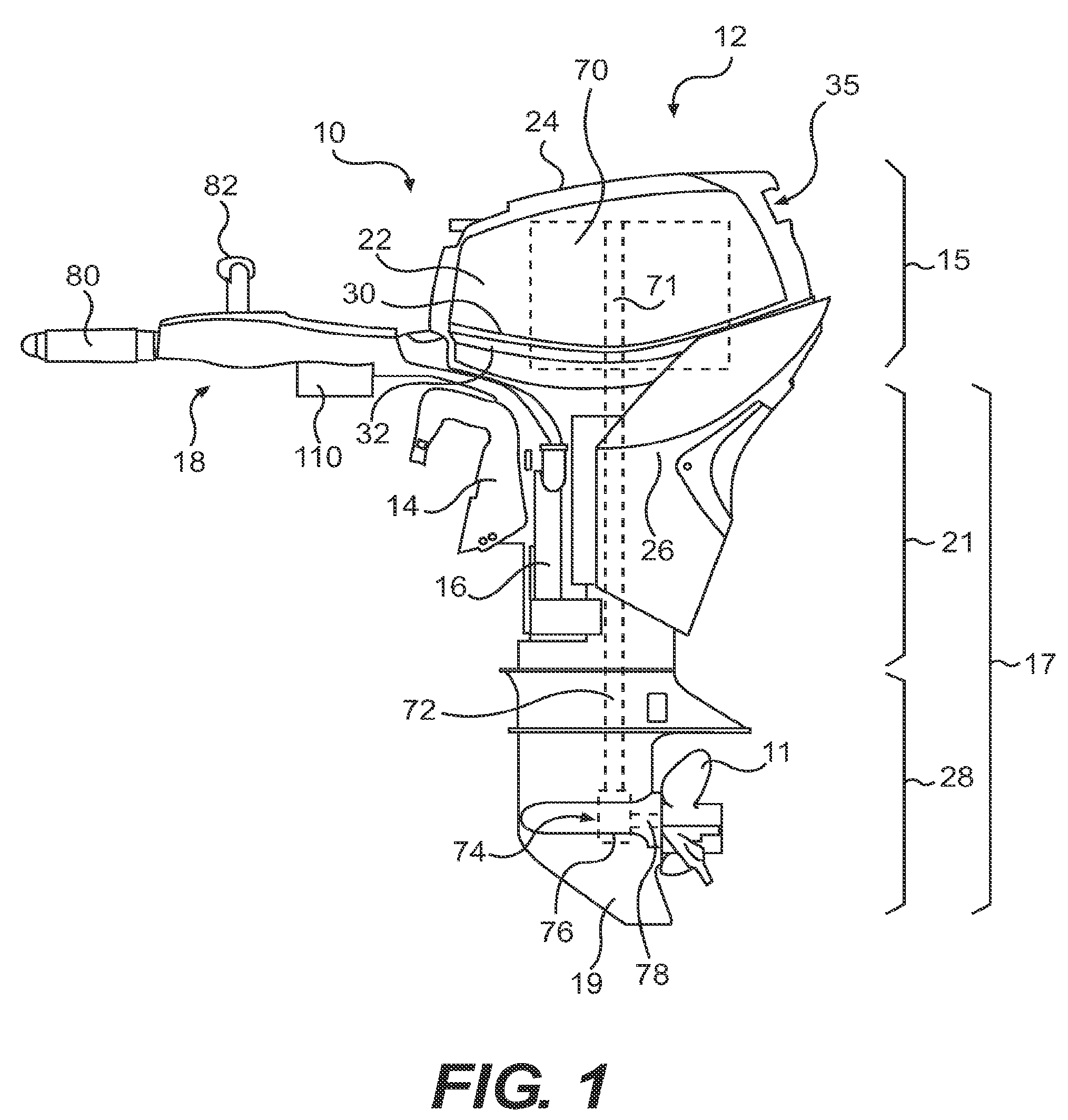

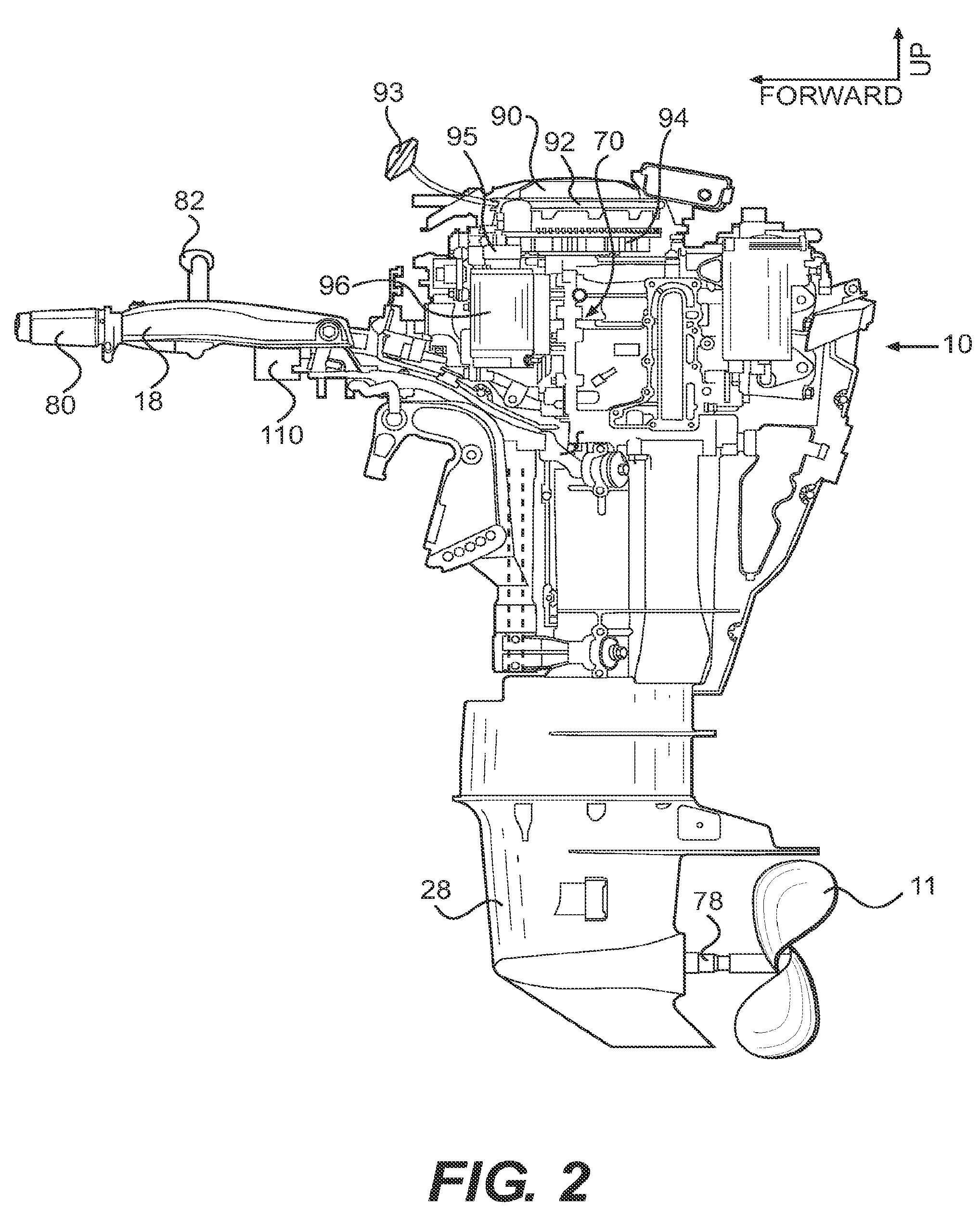

Engine starting system for a marine outboard engine

InactiveUS7704110B2Increasing weight and sizeSolution to short lifePropulsion power plantsMuscle operated startersAlternatorWatercraft

A marine outboard engine for a watercraft is disclosed. The marine outboard engine includes a starter motor operatively connected to the crankshaft of the engine and a capacitor electrically connected to the starter motor. The capacitor is powering the starter motor to initiate rotation of the crankshaft. An alternator is operatively connected to the engine and is electrically connected to the capacitor for charging the capacitor when the engine is operating. A starting system and a method for operating a starting system of a marine outboard engine are also disclosed.

Owner:BRP US

Engine starting system for a marine outboard engine

InactiveUS20090061705A1Reduce inconvenienceIncreasing weight and sizePropulsion power plantsMuscle operated startersAlternatorWatercraft

A marine outboard engine for a watercraft is disclosed. The marine outboard engine includes a starter motor operatively connected to the crankshaft of the engine and a capacitor electrically connected to the starter motor. The capacitor is powering the starter motor to initiate rotation of the crankshaft. An alternator is operatively connected to the engine and is electrically connected to the capacitor for charging the capacitor when the engine is operating. A starting system and a method for operating a starting system of a marine outboard engine are also disclosed.

Owner:BRP US

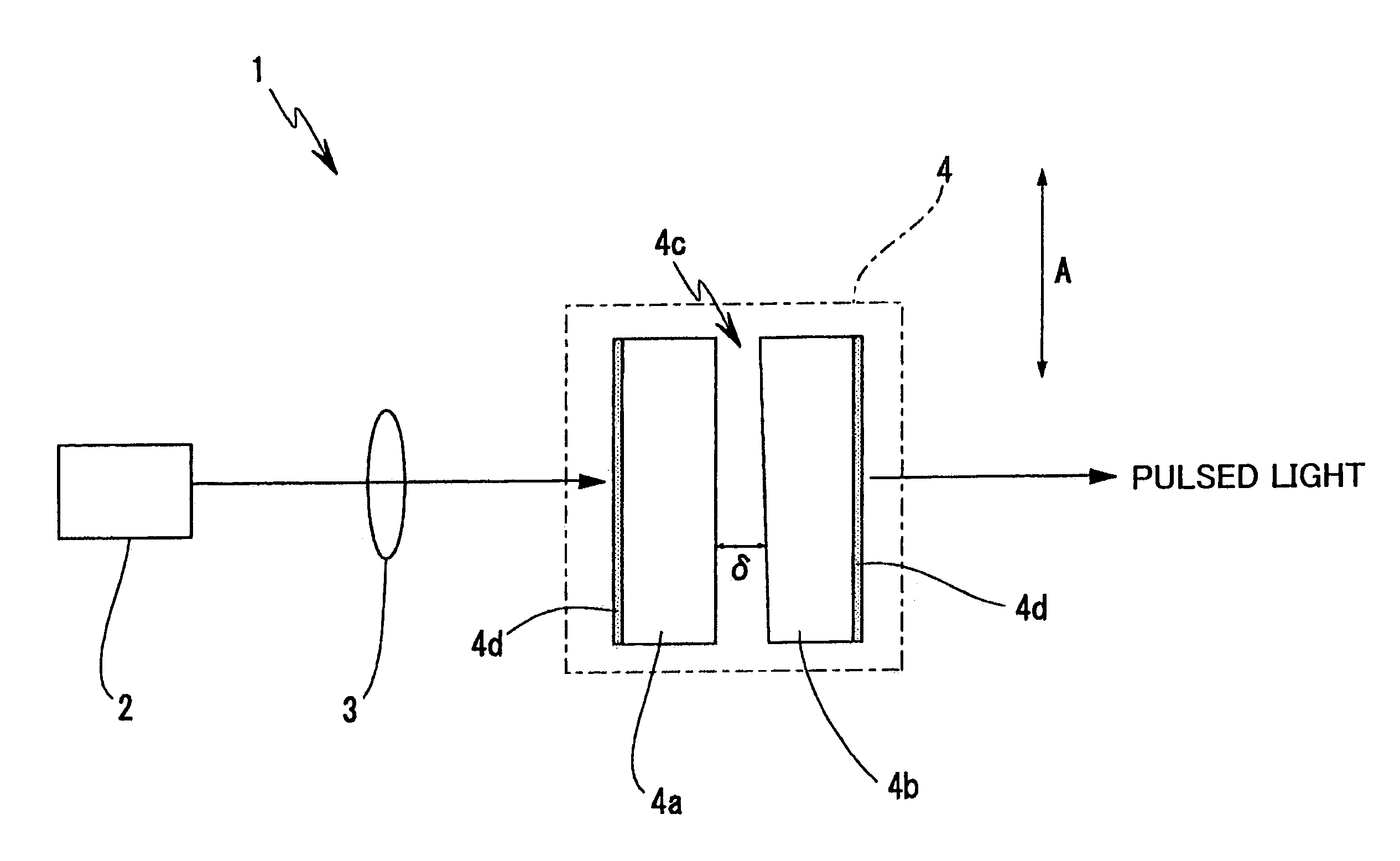

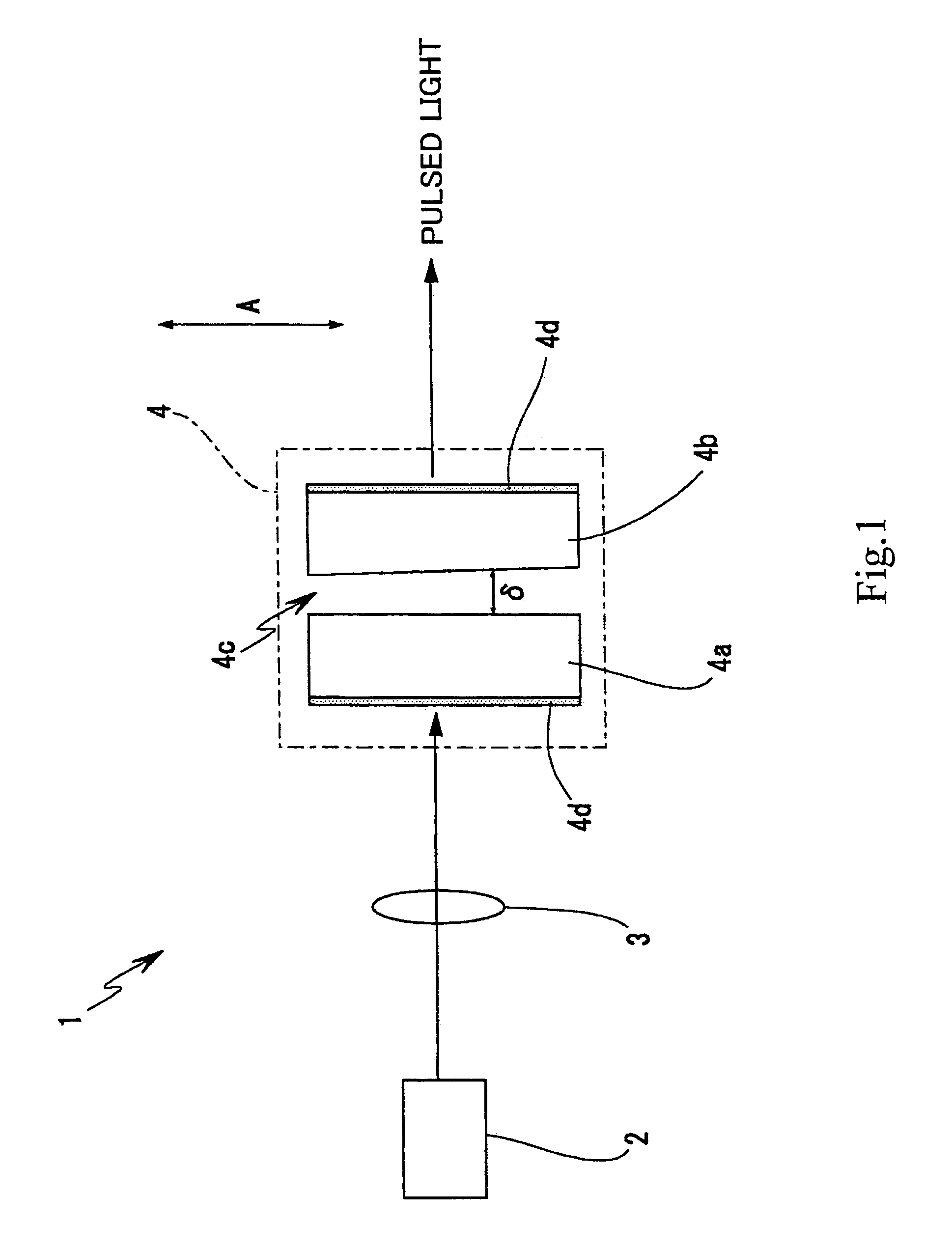

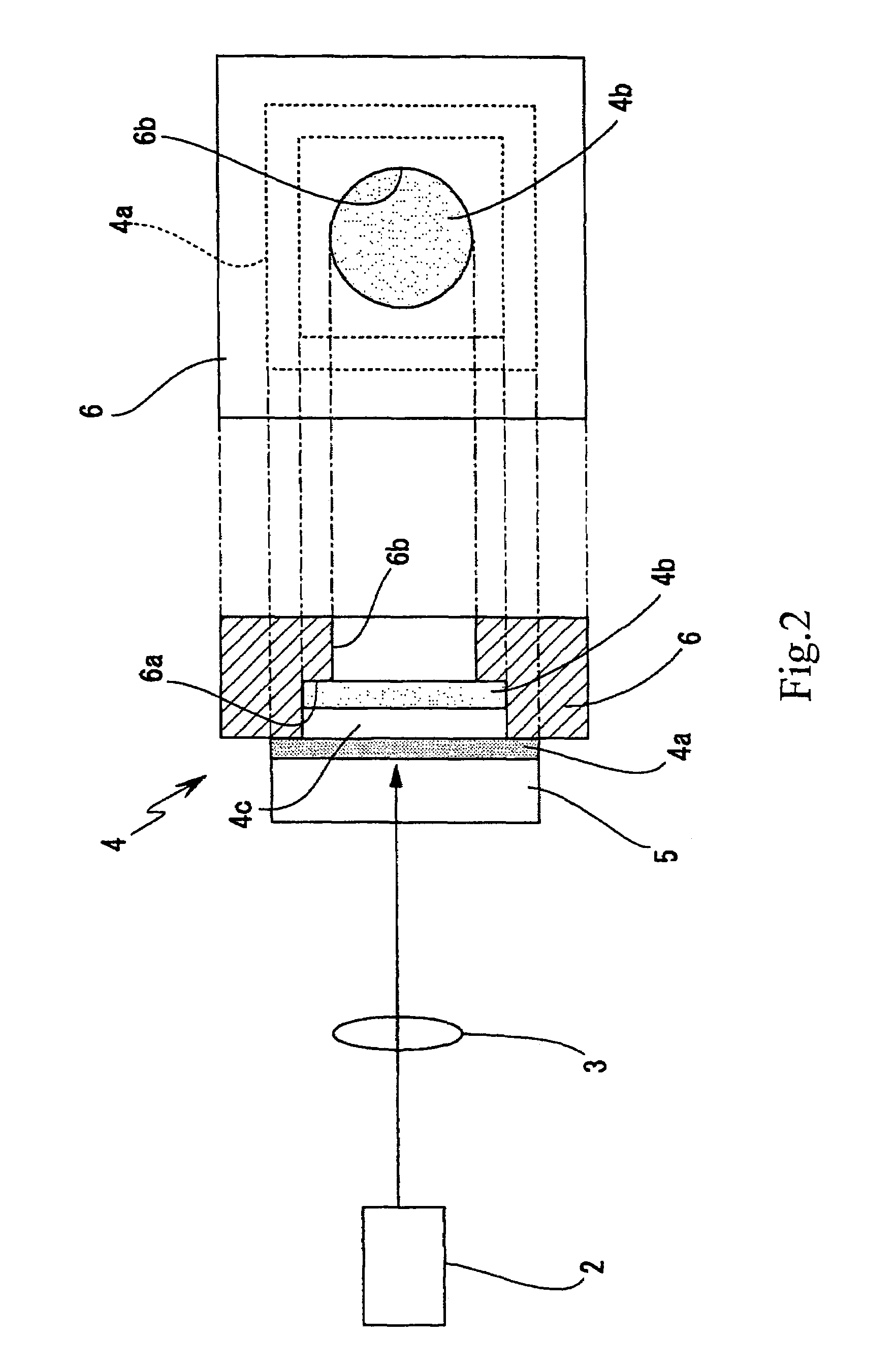

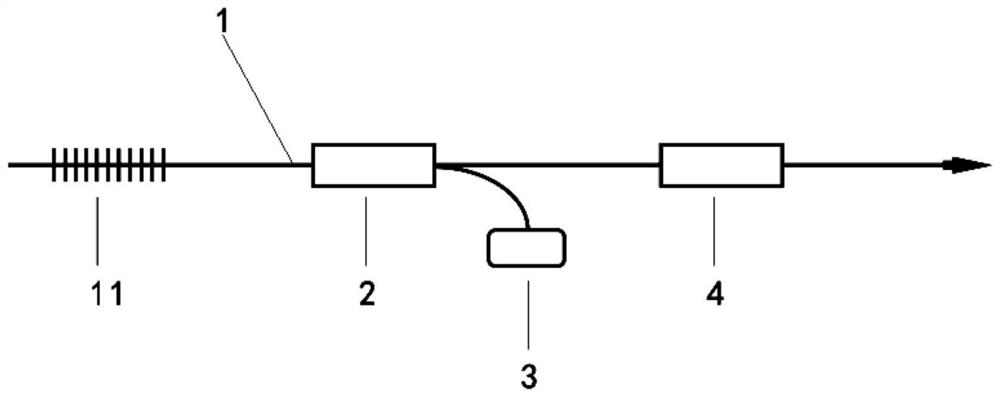

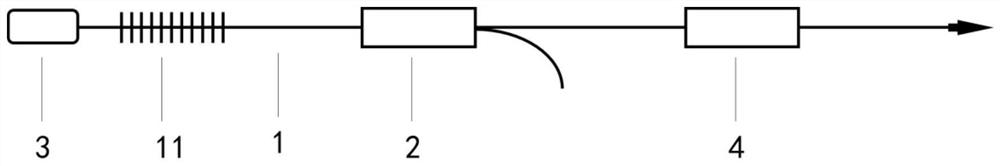

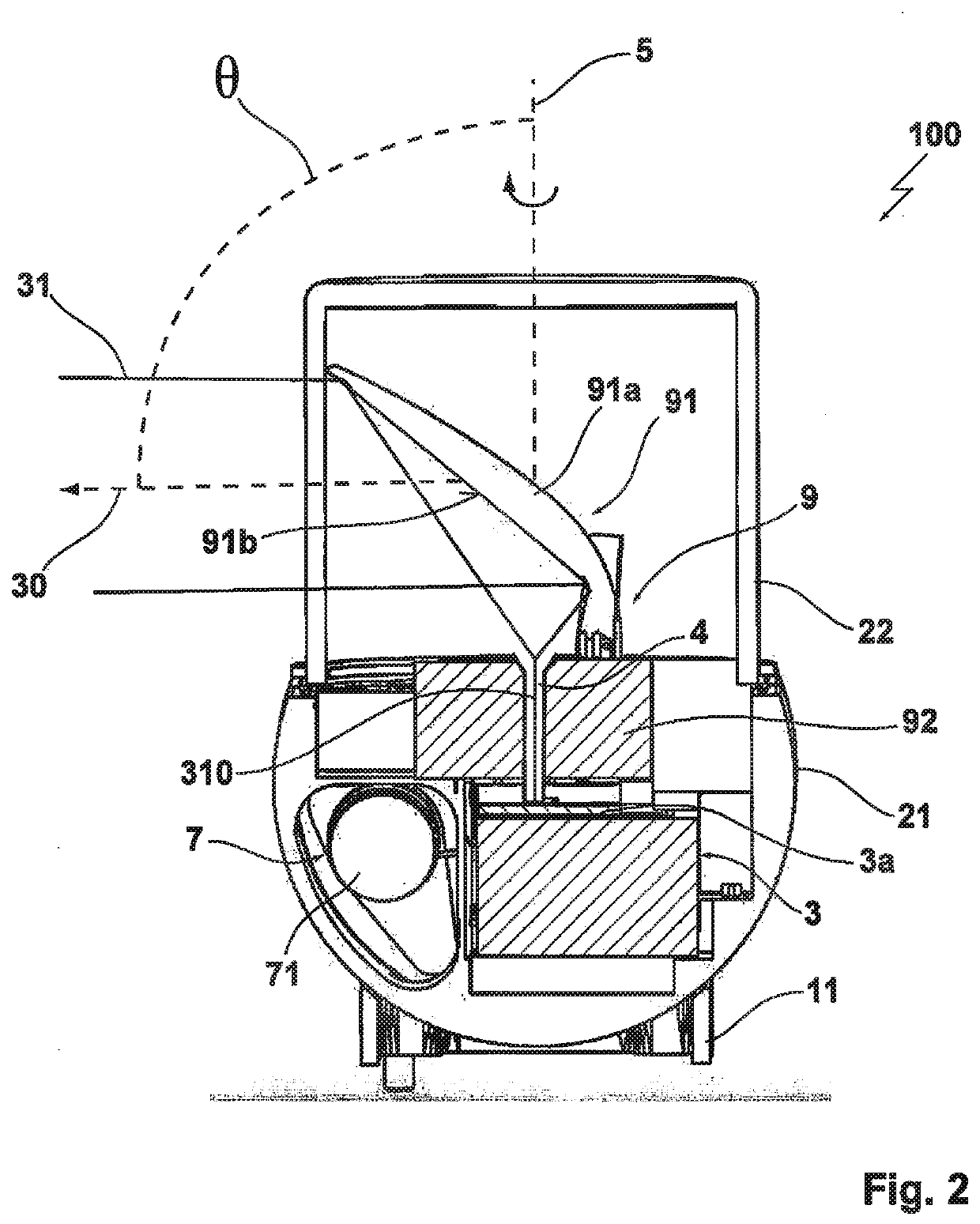

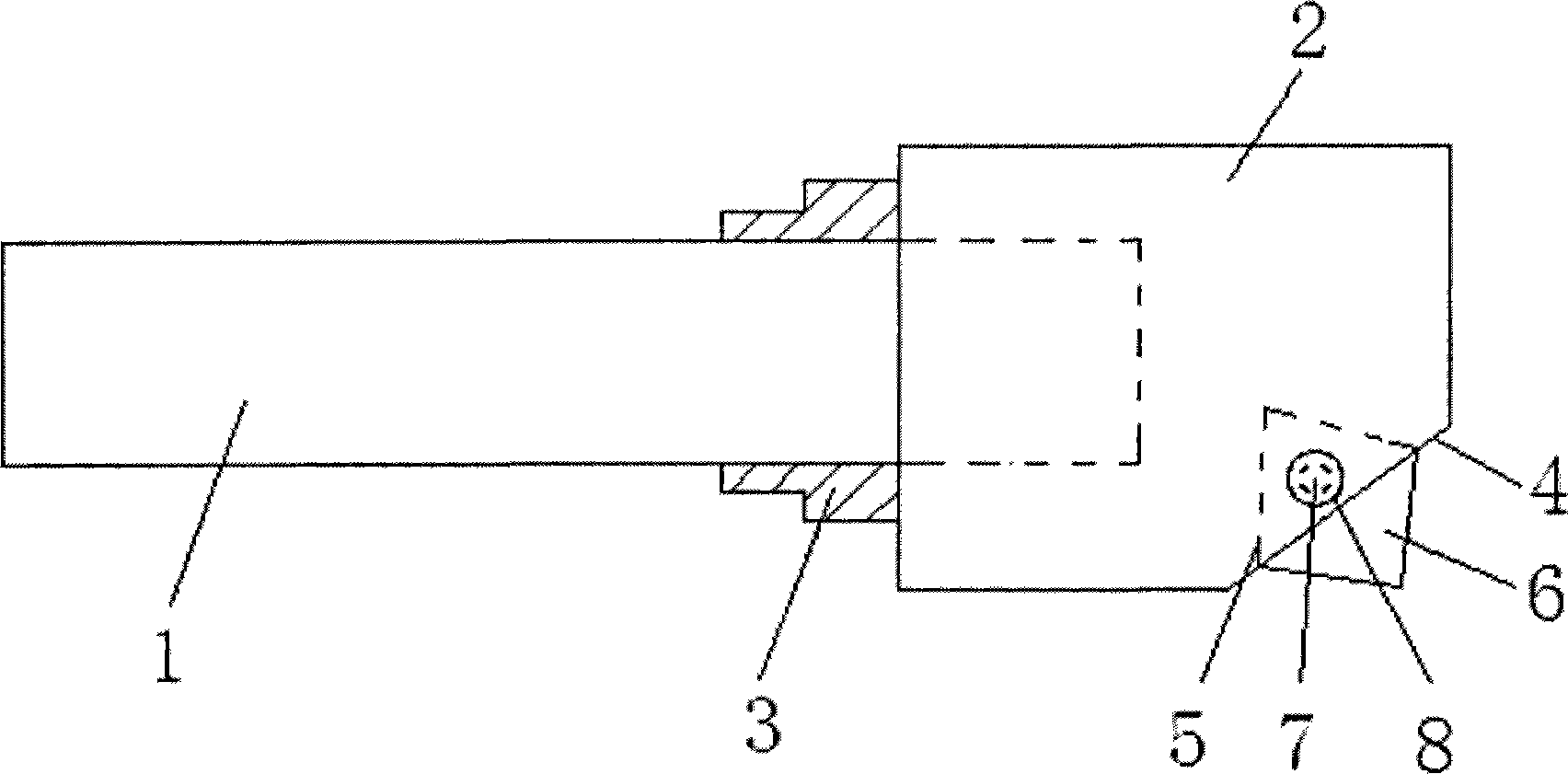

Laser light generating device and method of fabricating the same

InactiveUS7254148B2Less susceptible to vibrationOptical resonator shape and constructionActive medium materialPath lengthOperating point

In a laser light generating device, the stability against vibration and time-dependent changes will be improved, and influences of temperature changes exerted on the resonator will be reduced. In a laser light generating device (1) which includes an excitation light source (2) for generating a continuous-wave excitation light and a solid-state laser resonator (4) based on using thermal lens effect caused by heat generation at a position of excitation, the solid-state laser resonator further includes a laser medium (4a) a saturable absorber (4b) an intermediate medium (4c) and reflection means (4d) as the constituents. Influence of vibration is reduced by bonding a substrate of the laser medium (4a) and a substrate of the saturable absorber (4b) so as to integrate them. By adopting a configuration which does not need any method of selecting operating point based on temperature changes and is less susceptible to heat, and by relatively moving the excitation optical system and the resonator in the positional relation of the both to thereby adjust the light path length of the resonator, so as to make it possible to select a stable operating point.

Owner:SONY CORP

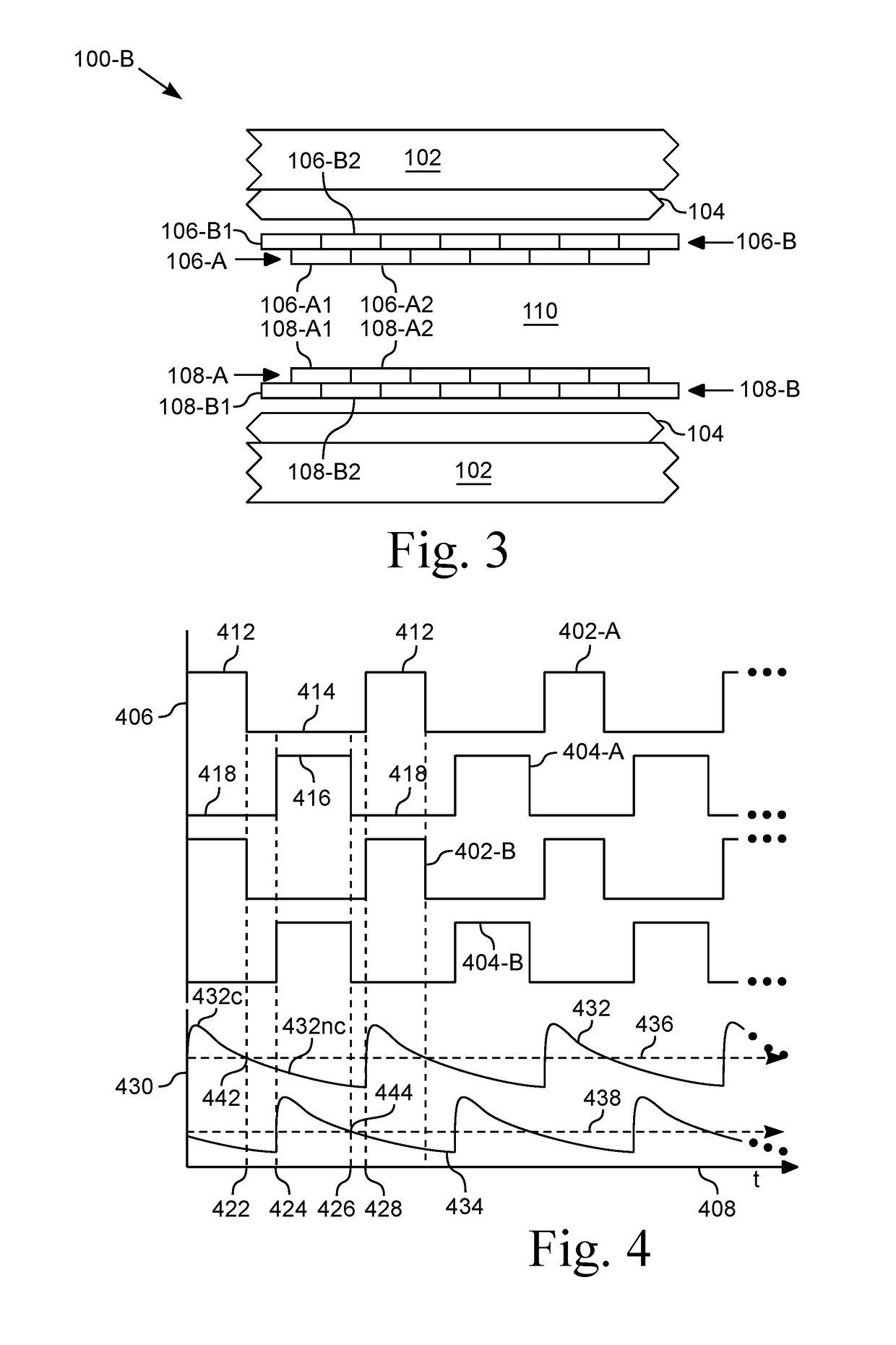

Method and apparatus for optical disc playback

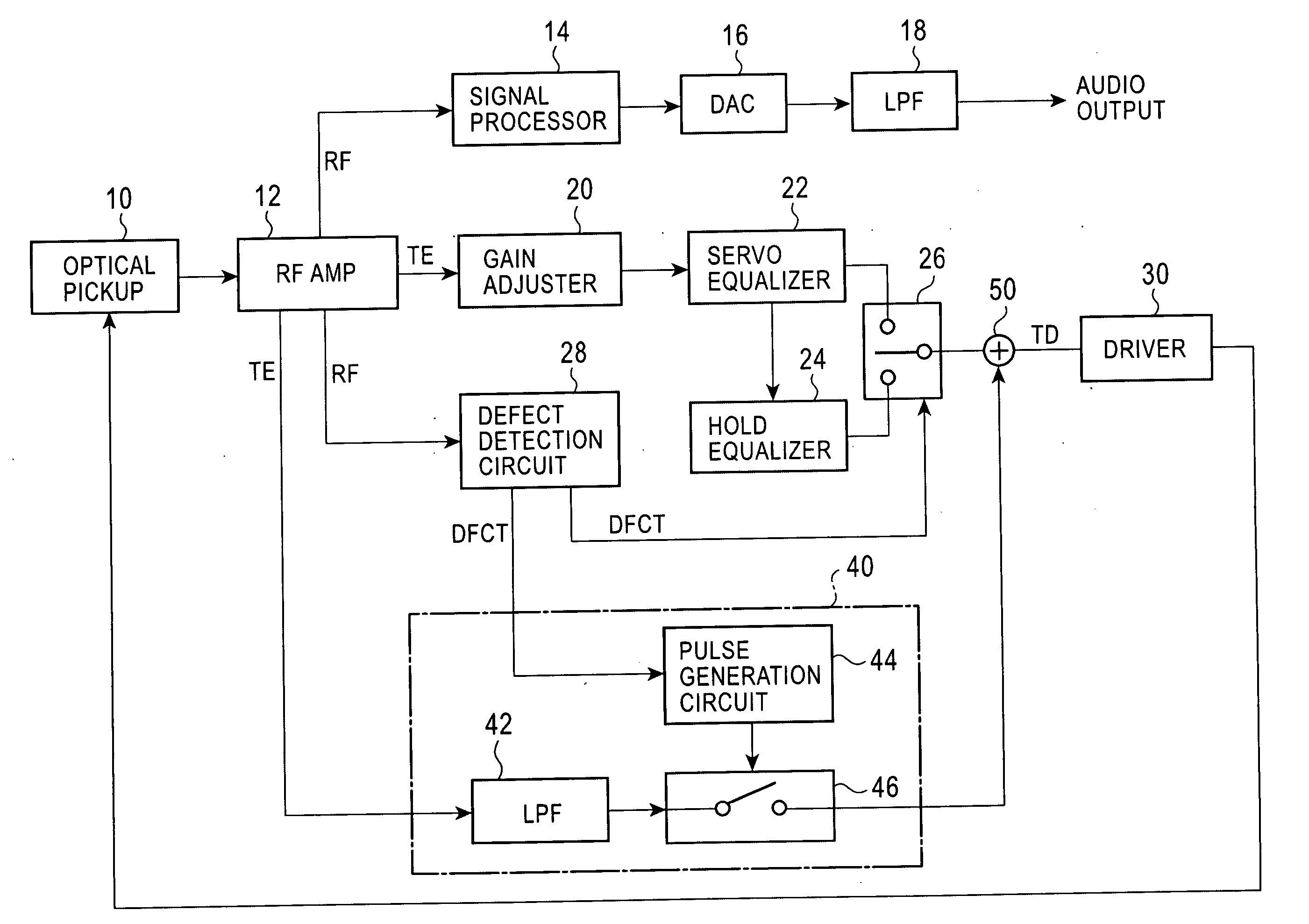

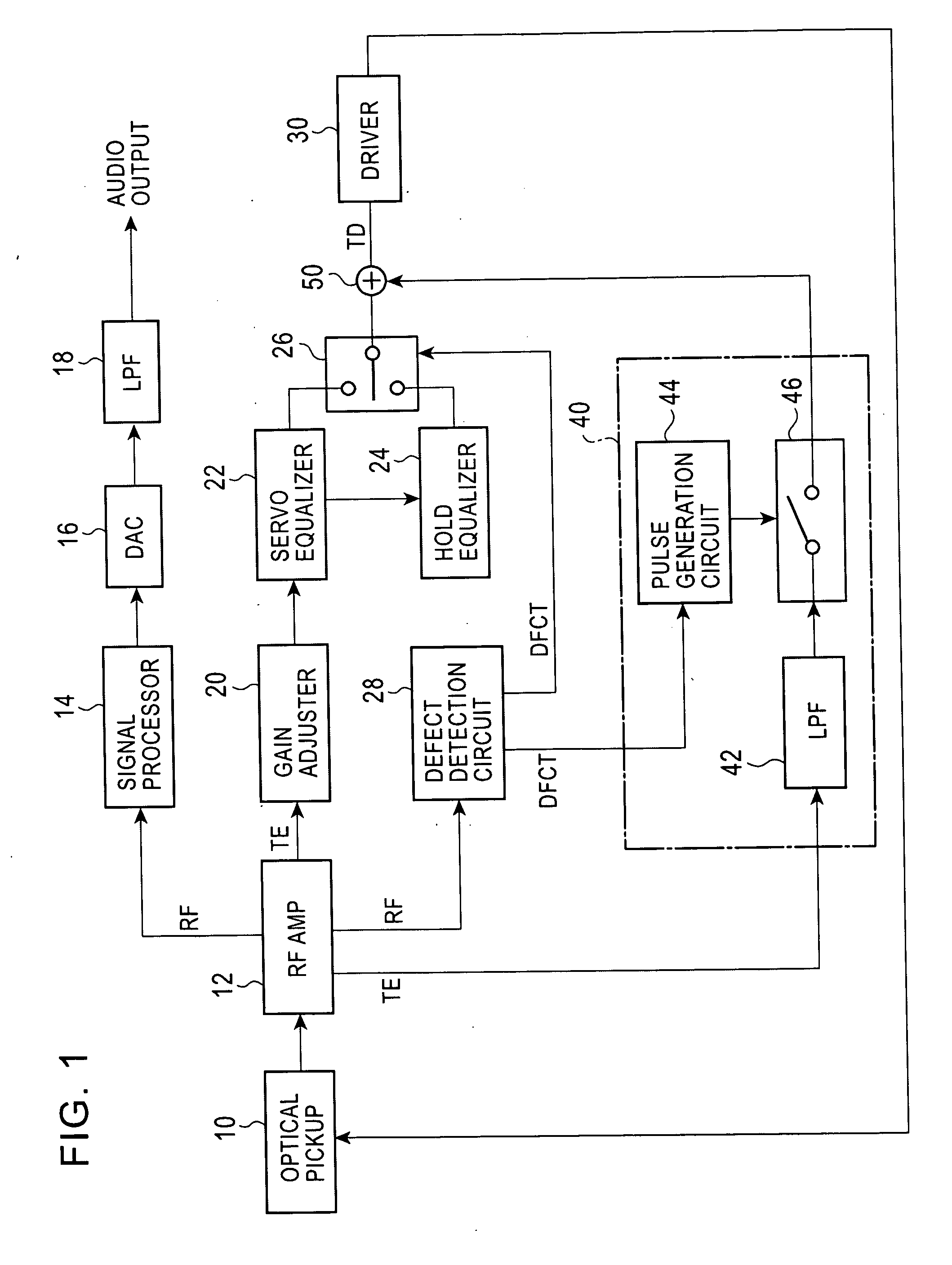

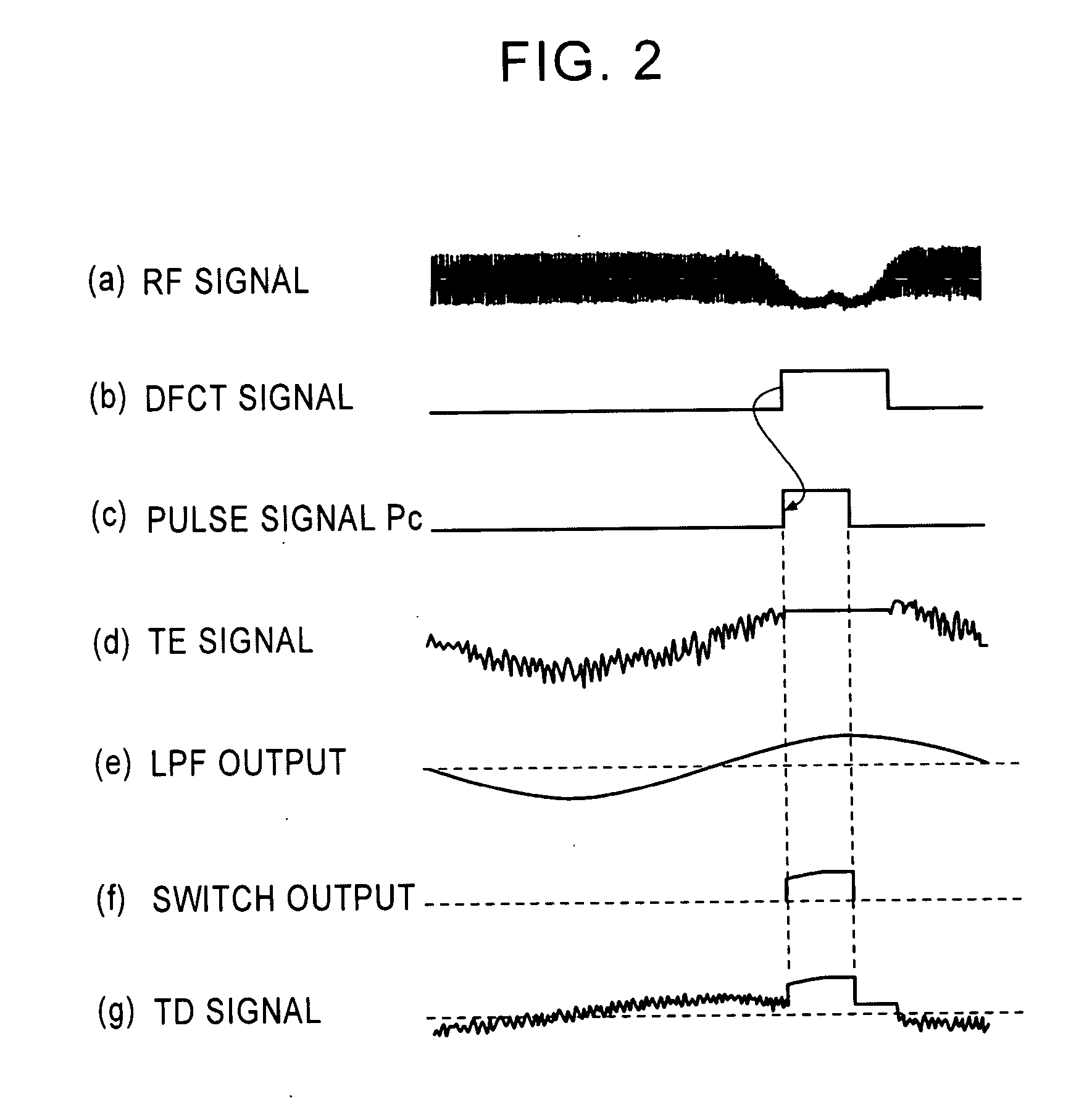

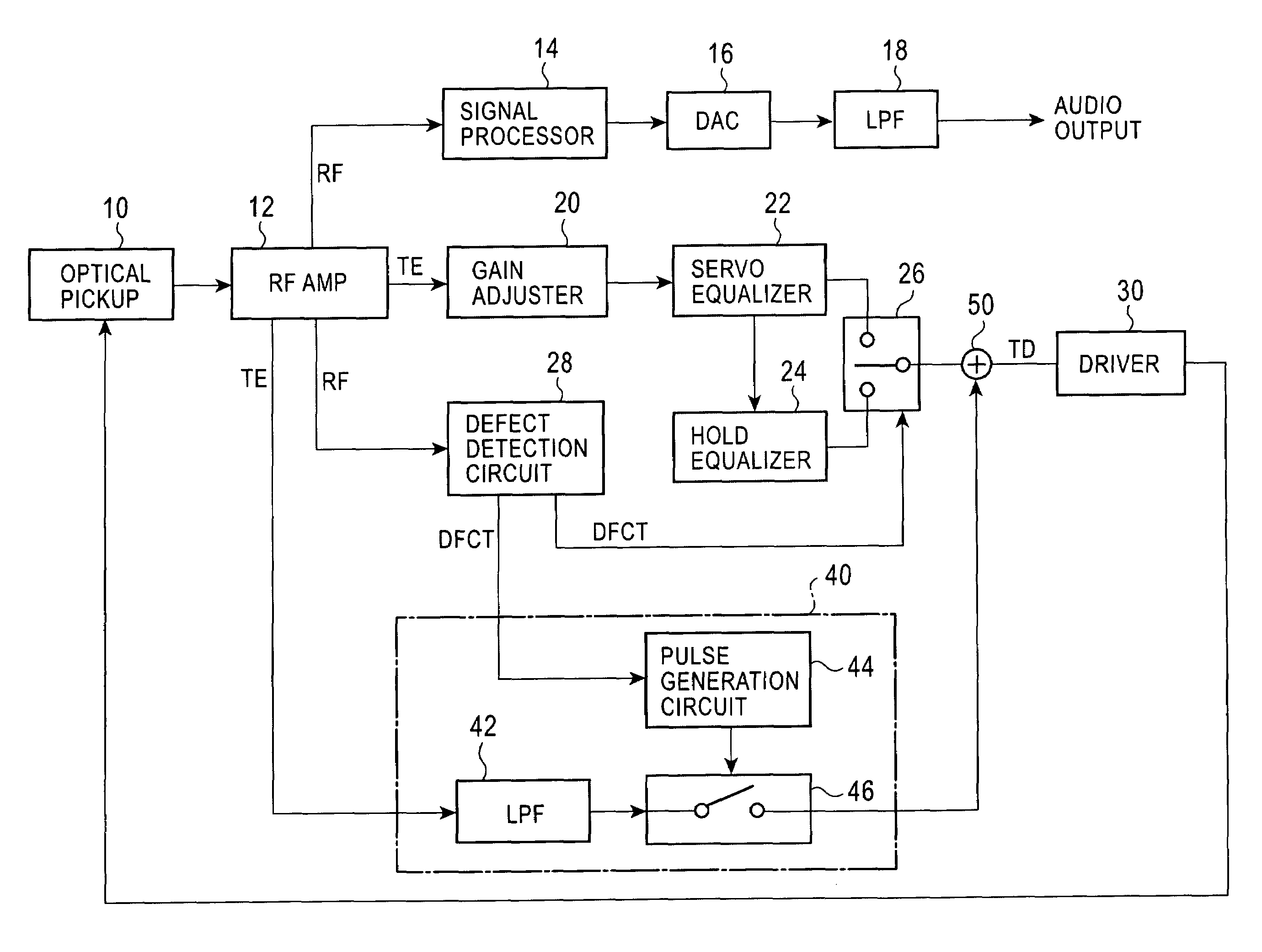

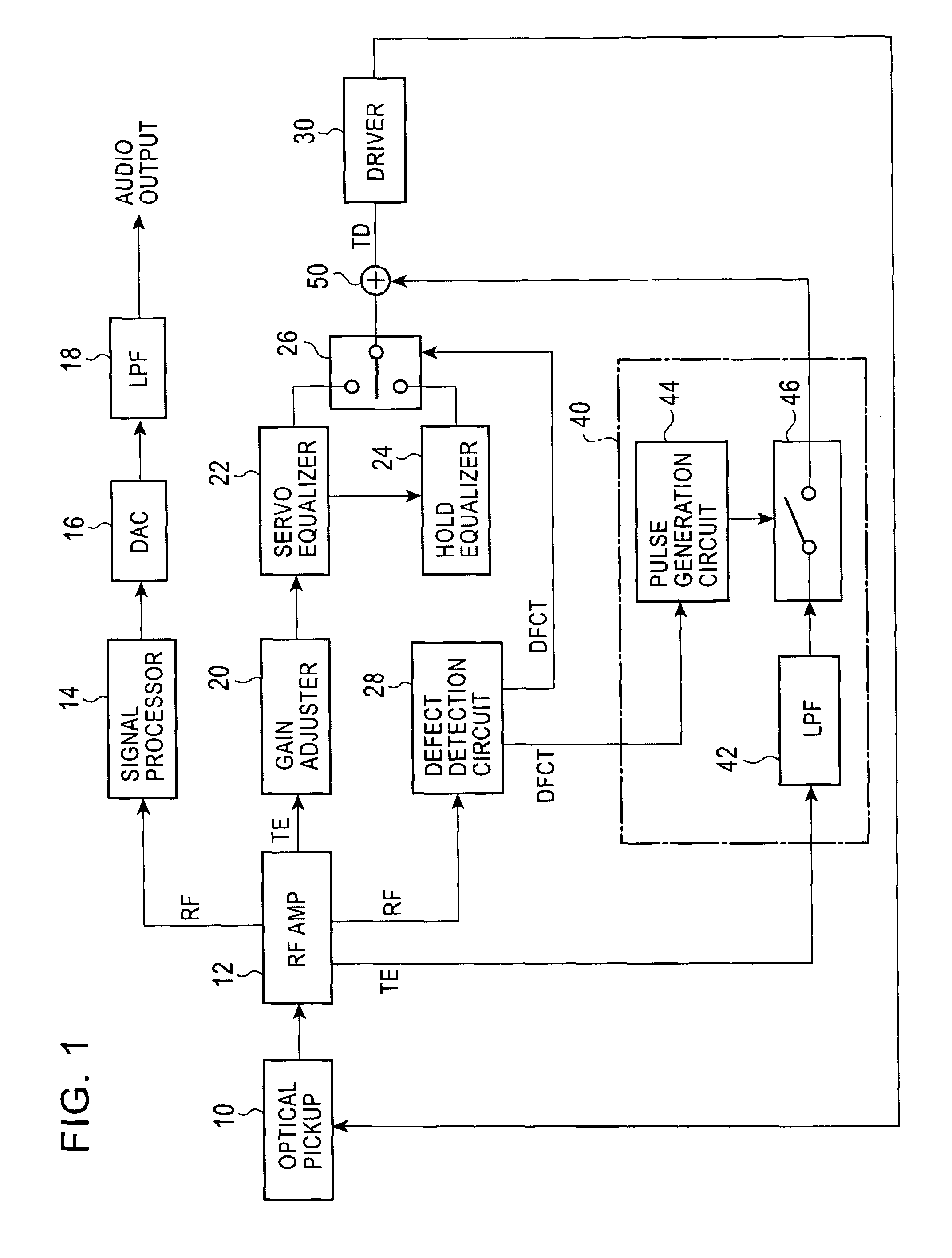

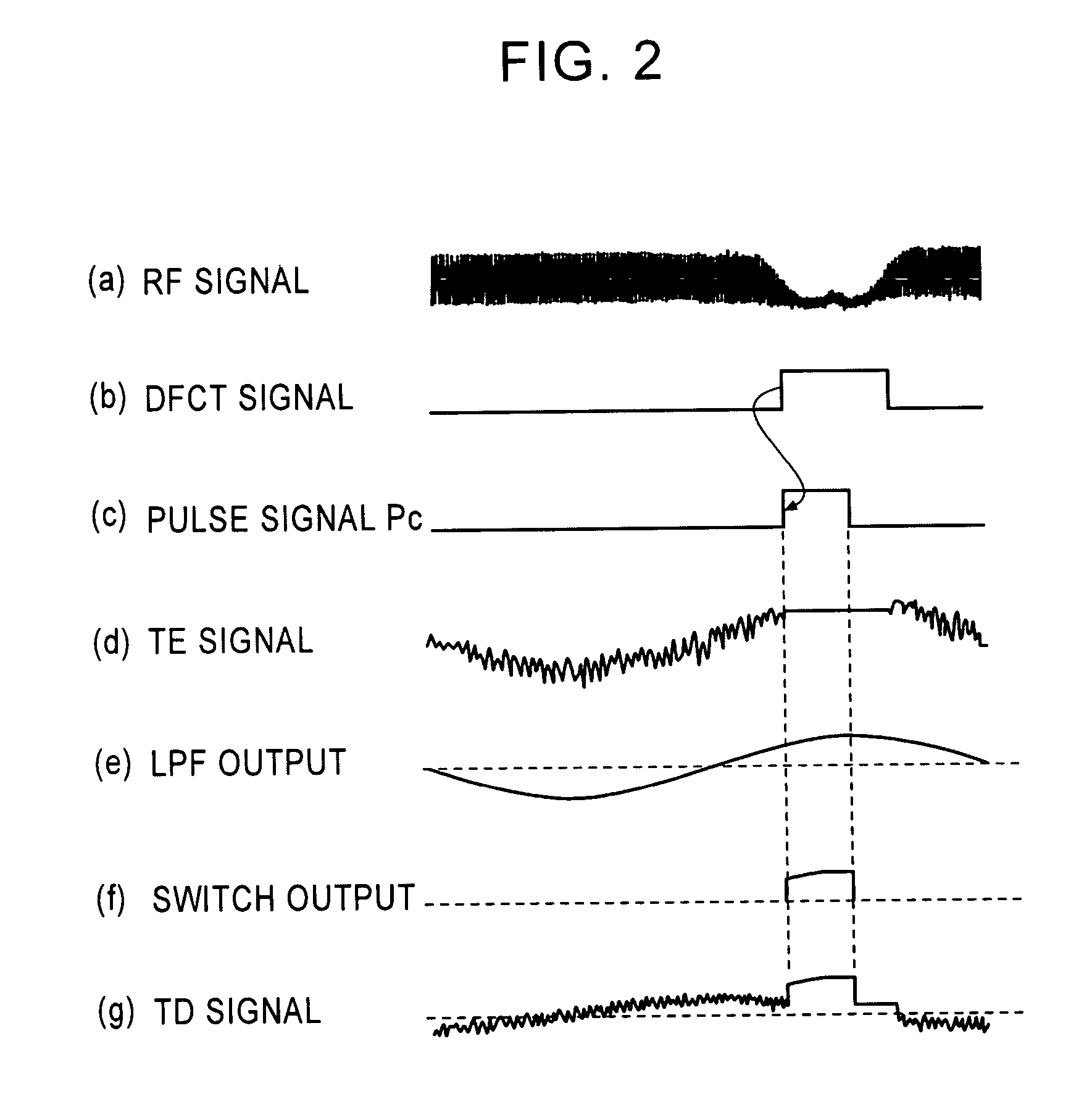

InactiveUS20050169146A1Improve the immunityLess susceptible to vibrationCombination recordingRecord information storageOptical pickupEngineering

An optical disc playback apparatus includes an optical pickup, an RF amplifier that generates a tracking error (TE) signal based on an electrical signal from the optical pickup, a defect detector that detects a defect on the optical disc and that outputs a DFCT signal indicating the detected defect, a switch that outputs a hold signal when a defect is detected based on the DFCT signal, a driver that controls the optical pickup based on the output signal of the switch, a corrector that extracts an oscillation component of the optical pickup from the TE signal in response to the DFCT signal when a defect is detected and that outputs a correction signal indicating the oscillation component, and an adder that adds the correction signal from the corrector to the hold signal.

Owner:ALPINE ELECTRONICS INC

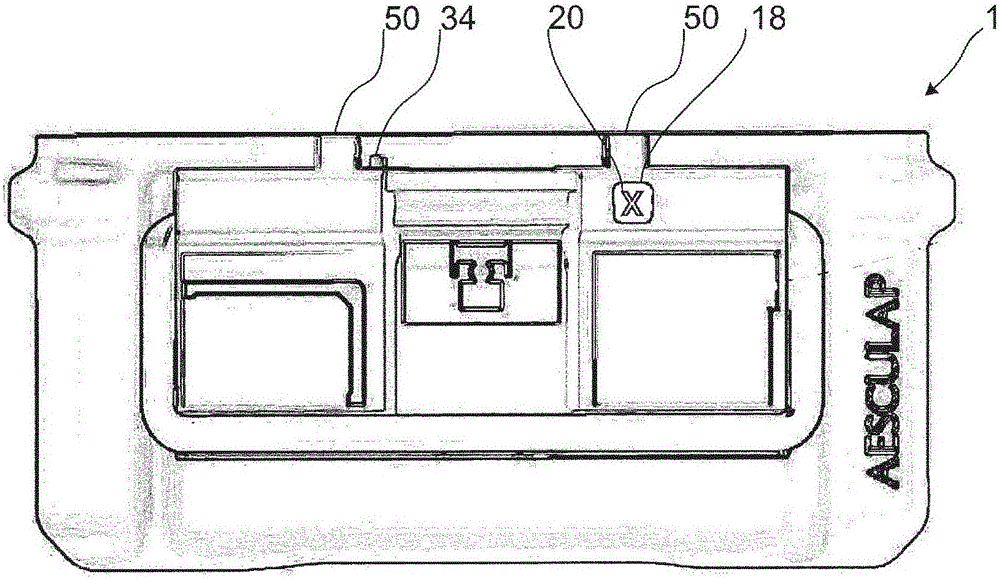

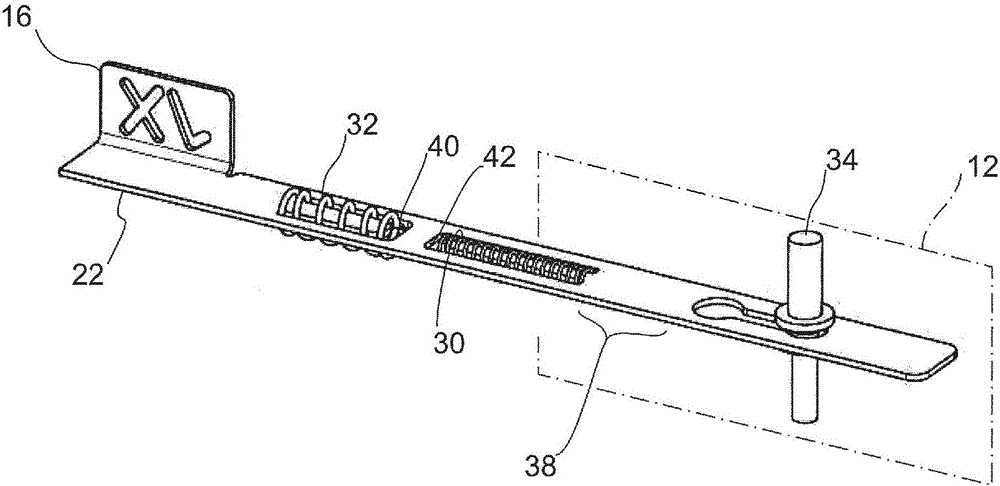

Sterilization indicator for a sterile container

ActiveCN105682695ASolution to short lifeReduce loadEngine sealsSurgical furnitureLocking mechanismCoil spring

The present invention discloses a sterilization indicator for a sterile container, having a shape-memory element in the form of an axially acting compression spring, preferably of the helical-spring type, which, when a predetermined sterilization temperature is reached or exceeded, subjects an indicating unit to a defined axial compressive force, said indicating unit, in turn, being prestressed by means of a restoring spring, preferably of the helical-spring type, in the direction counter to the shape-memory element by way of a restoring force which is smaller than the defined axial compressive force, and having a latching mechanism, which can be actuated by a manually actuable closing or locking mechanism of the sterile container and is designed such that, following or during the operation of the sterile container being closed or locked, it retains the indicating unit in a sterile position once said unit has been moved into the sterile position by the shape-memory element and, upon opening or unlocking of the sterile container below the sterilization temperature, it frees the indicating unit, whereupon the restoring spring moves the indicating unit back into an unsterile position.

Owner:AESCULAP AG

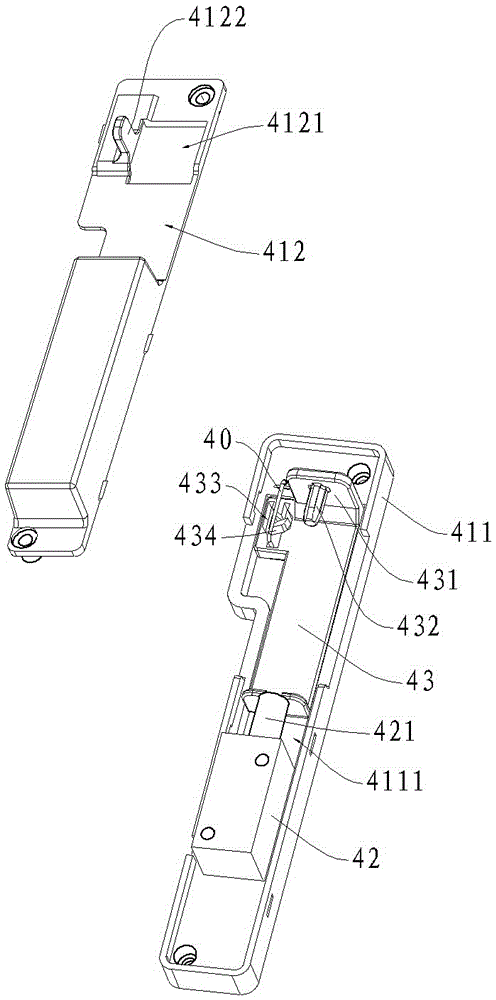

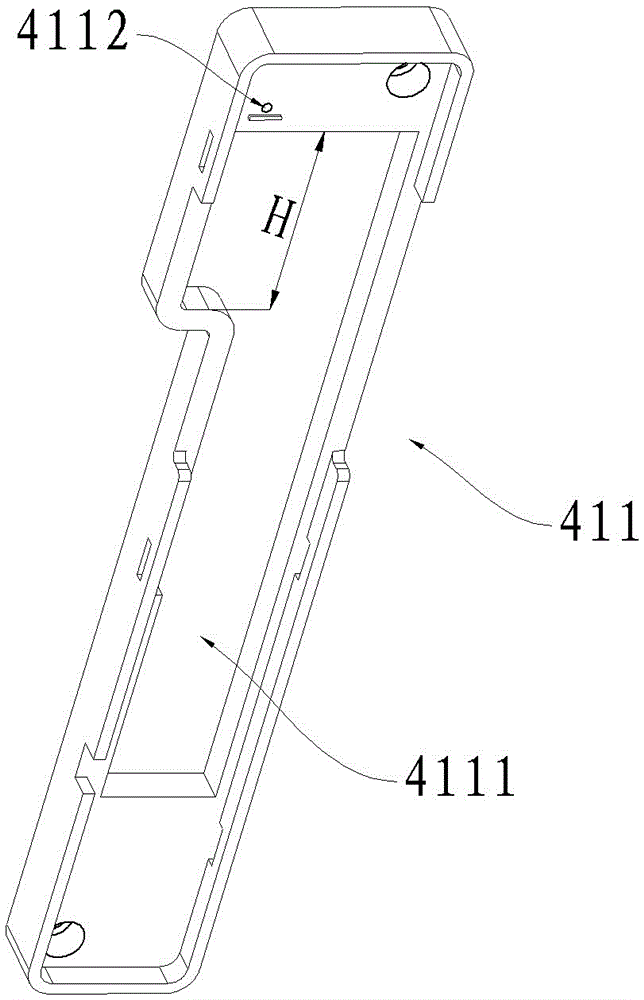

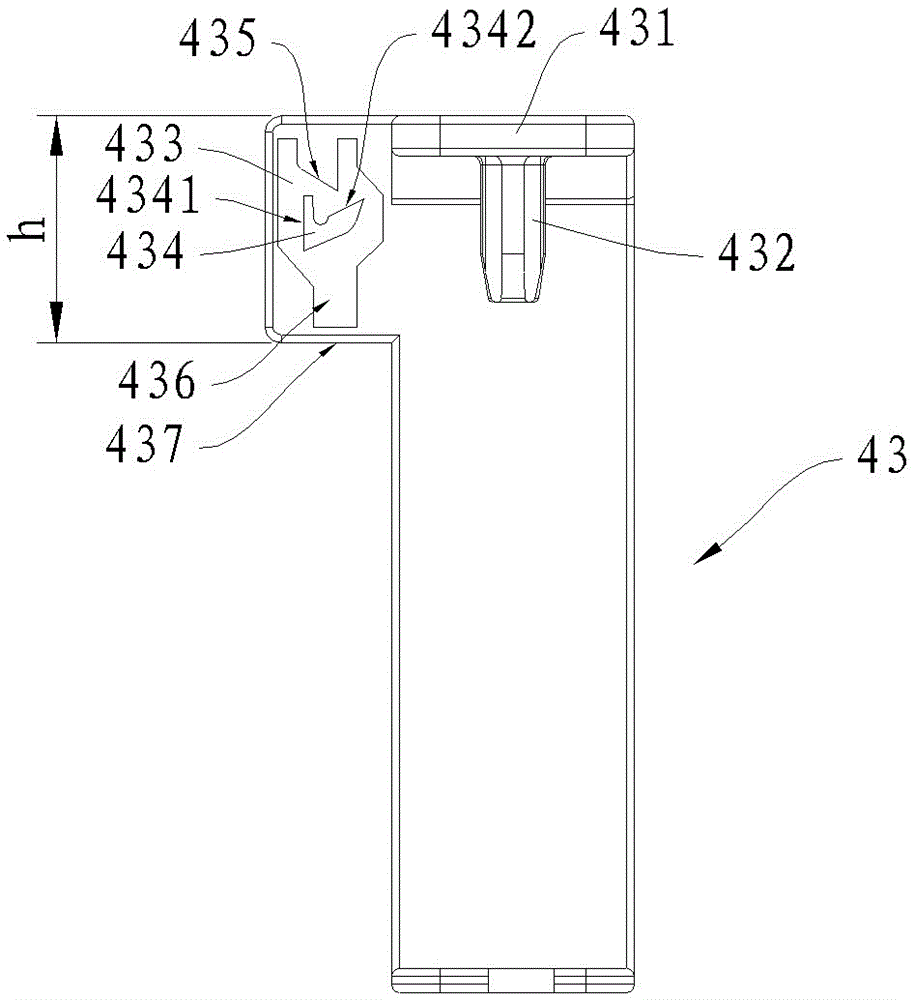

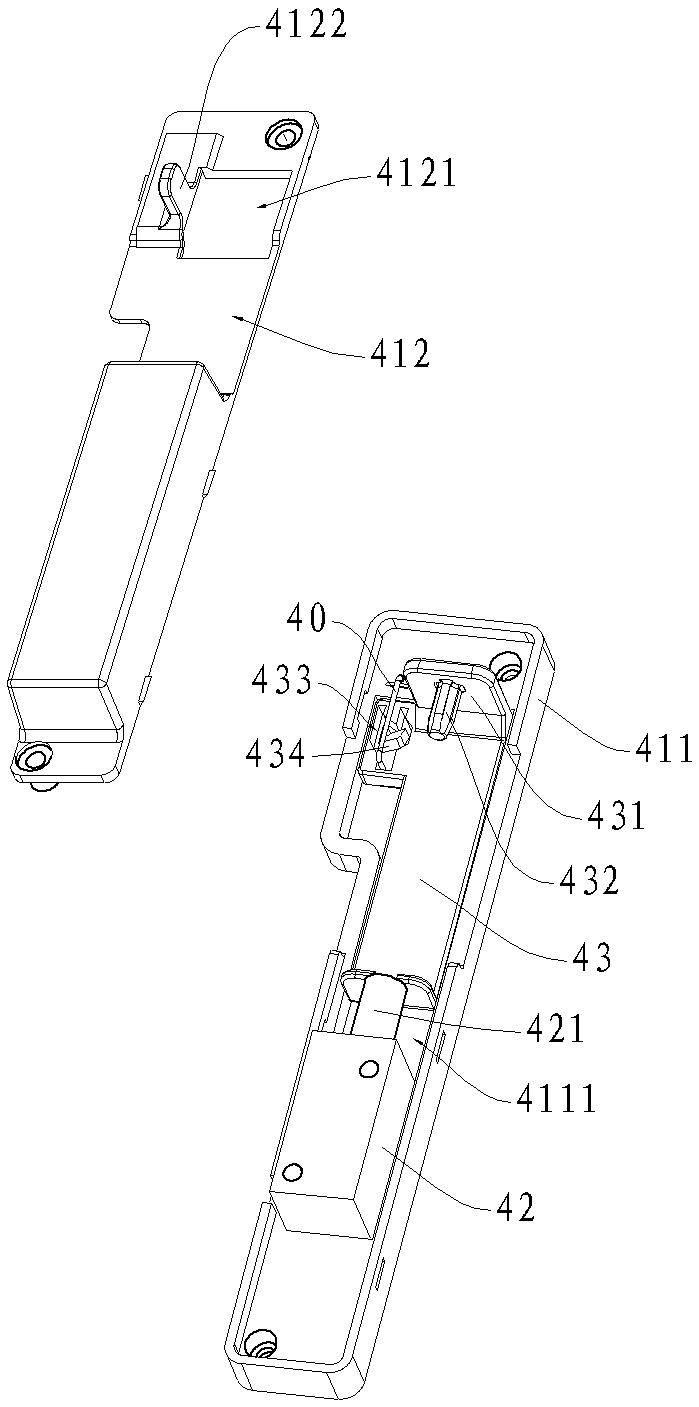

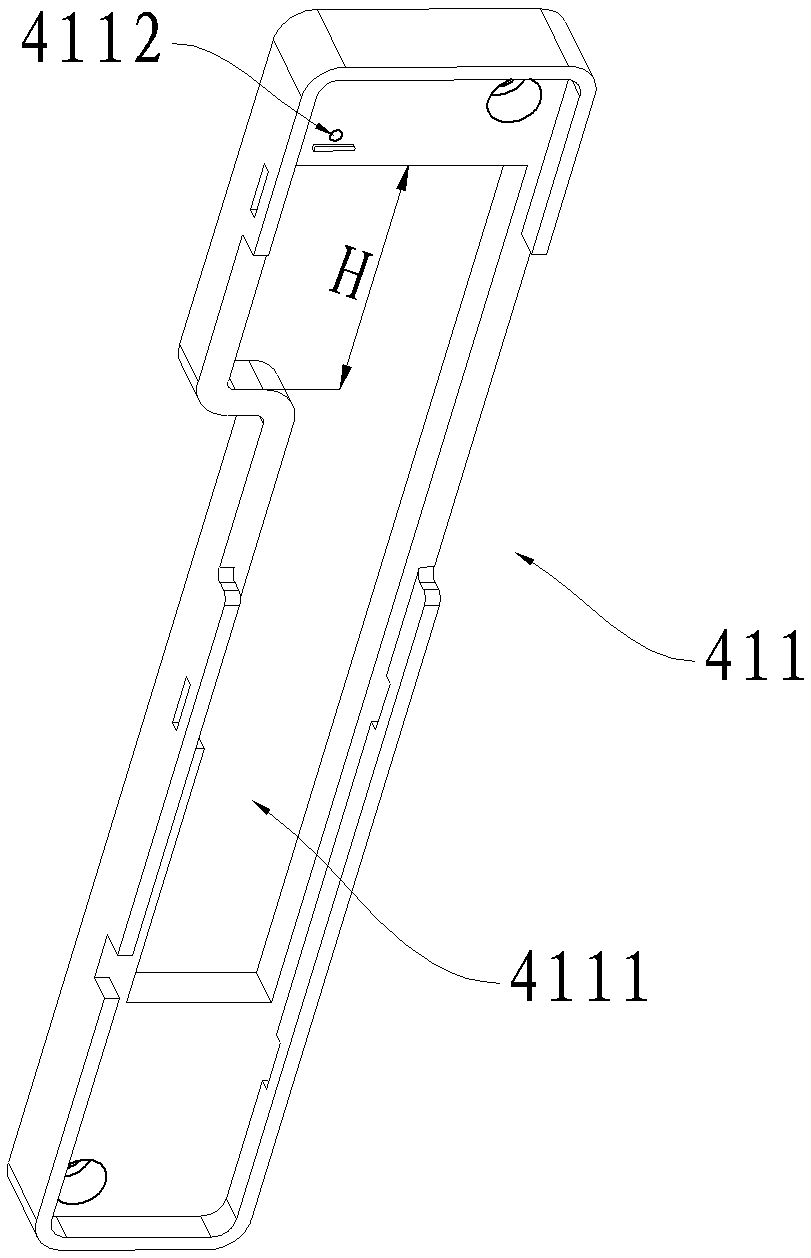

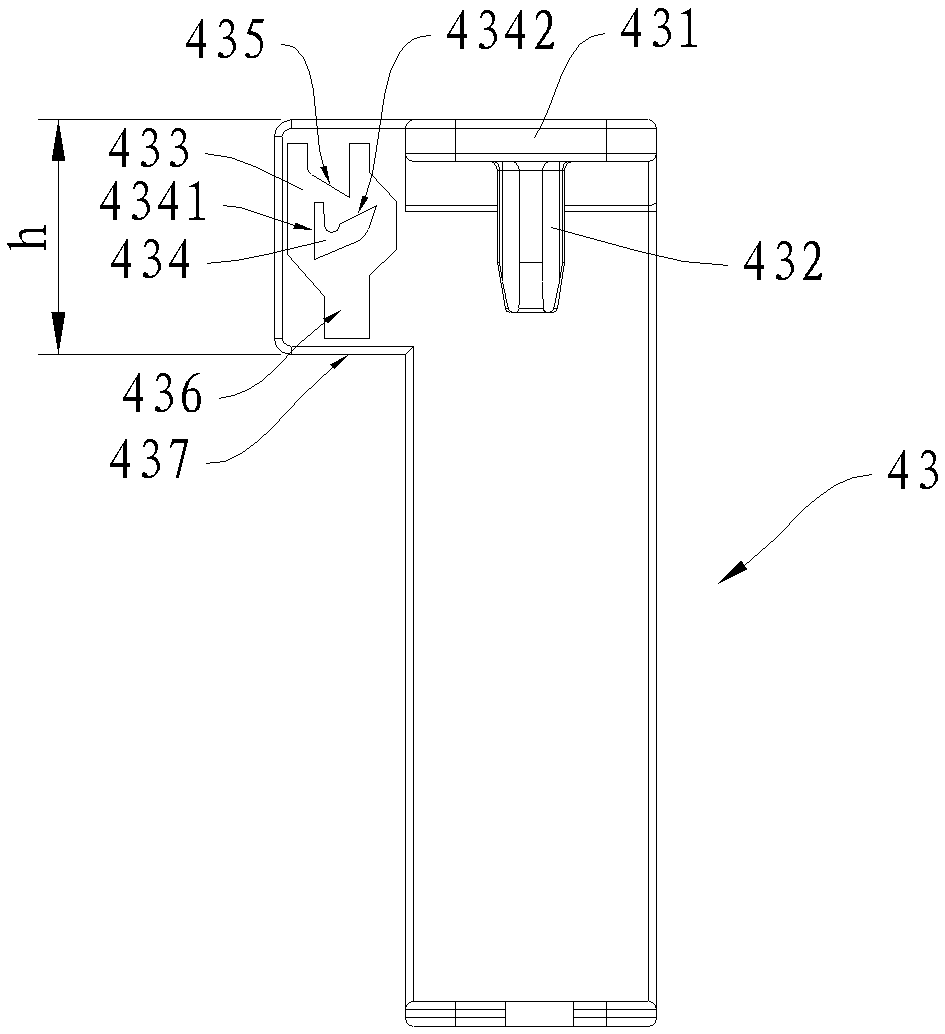

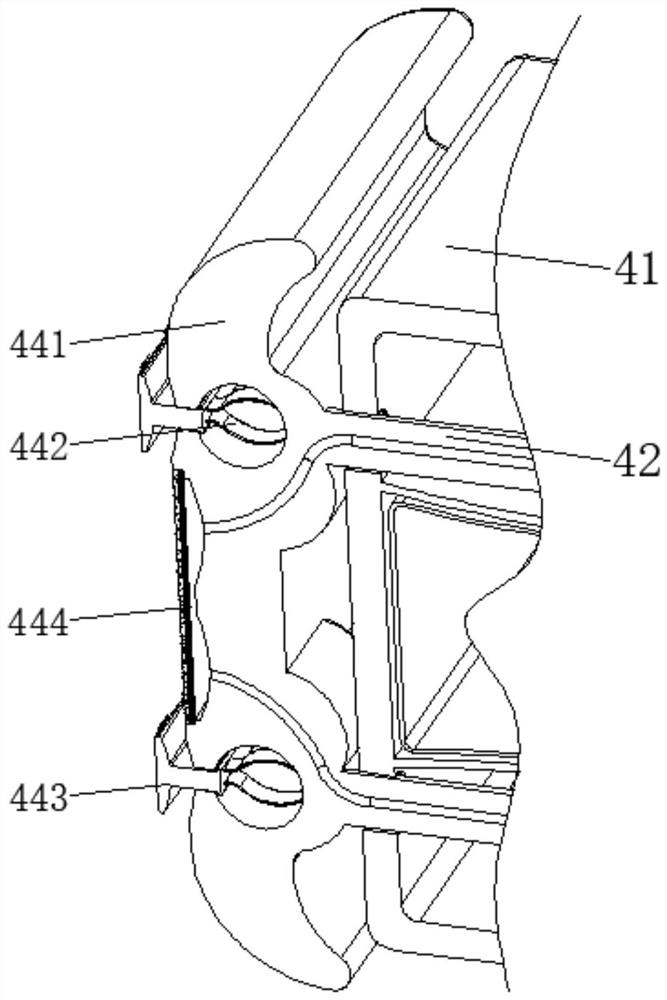

Sliding rail with self-locking function

The invention provides a sliding rail with a self-locking function, which can solve the problems that the service life of a lock catch is short because of long-term use impact and the sealing performance of an electrical appliance is poor in the kitchen electrical appliance which is provided with a pulling basket drawer. The sliding rail with the self-locking function comprises a fixed guide rail and a movable guide rail; the movable guide rail is mounted on the fixed guide rail in a sliding manner; a sliding rail door plate bracket is mounted at the front end of the movable guide rail; the sliding rail door plate bracket is fixed and connected to a pulling basket drawer door plate; the fixed guide rail is fixedly mounted on a liner frame of the electrical appliance; an electromagnetic locking system is mounted on the side surface, which faces the liner wall of the electrical appliance, of the rear end part of the fixed guide rail; a pin hole is formed in the top surface of the rear end of the movable guide rail; the electromagnetic locking system can act when the fixed guide rail and the movable guide rail are positioned in a closed position so as to realize the locking or unlocking between the electromagnetic locking system and the pin hole.

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

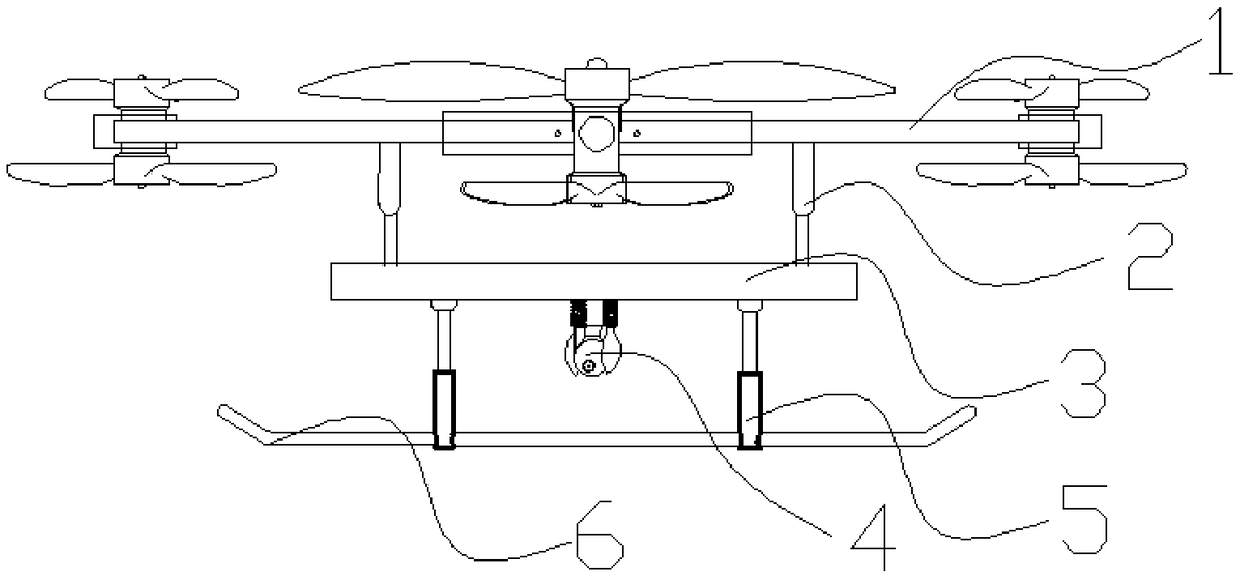

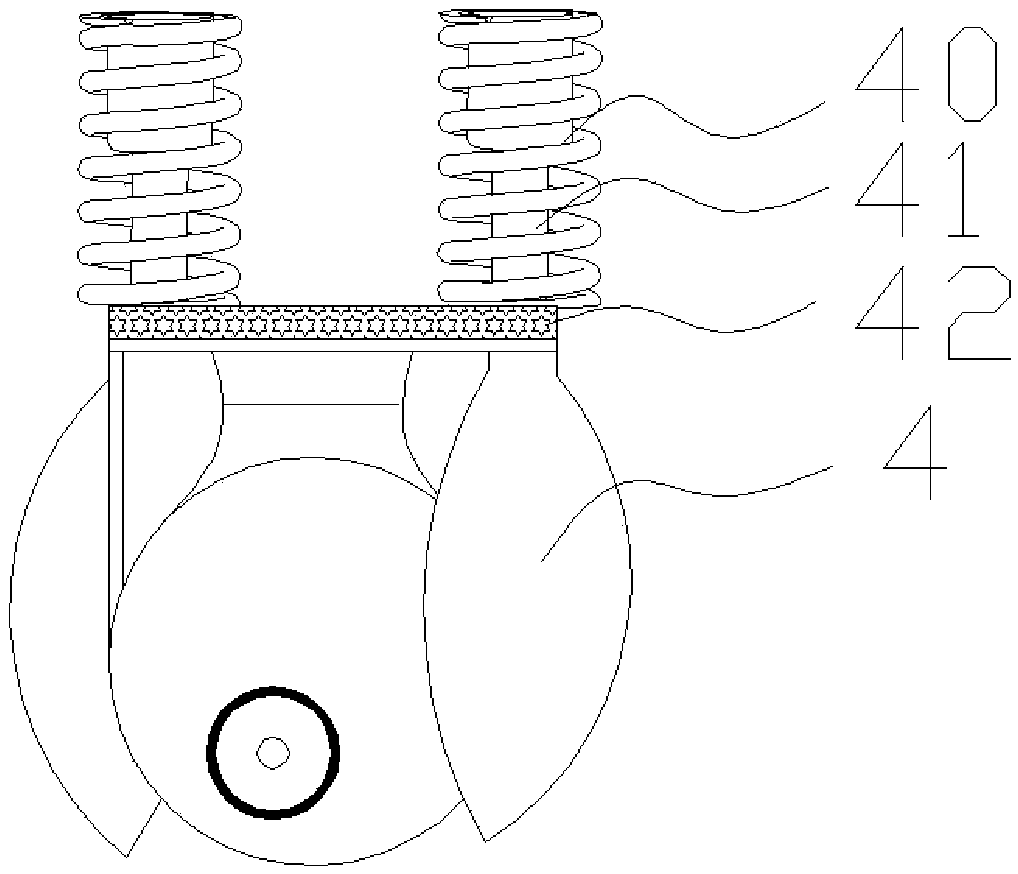

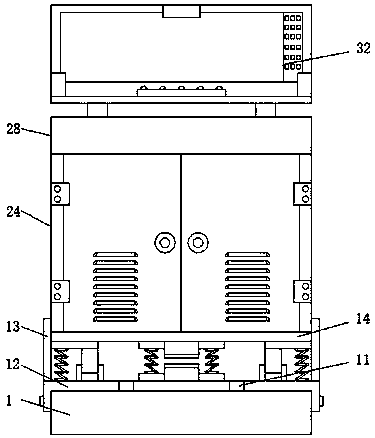

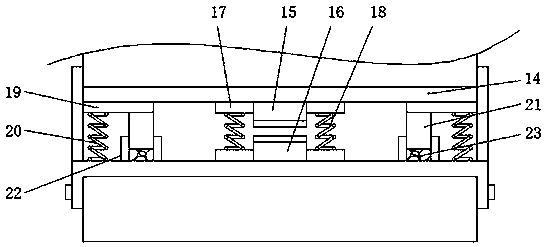

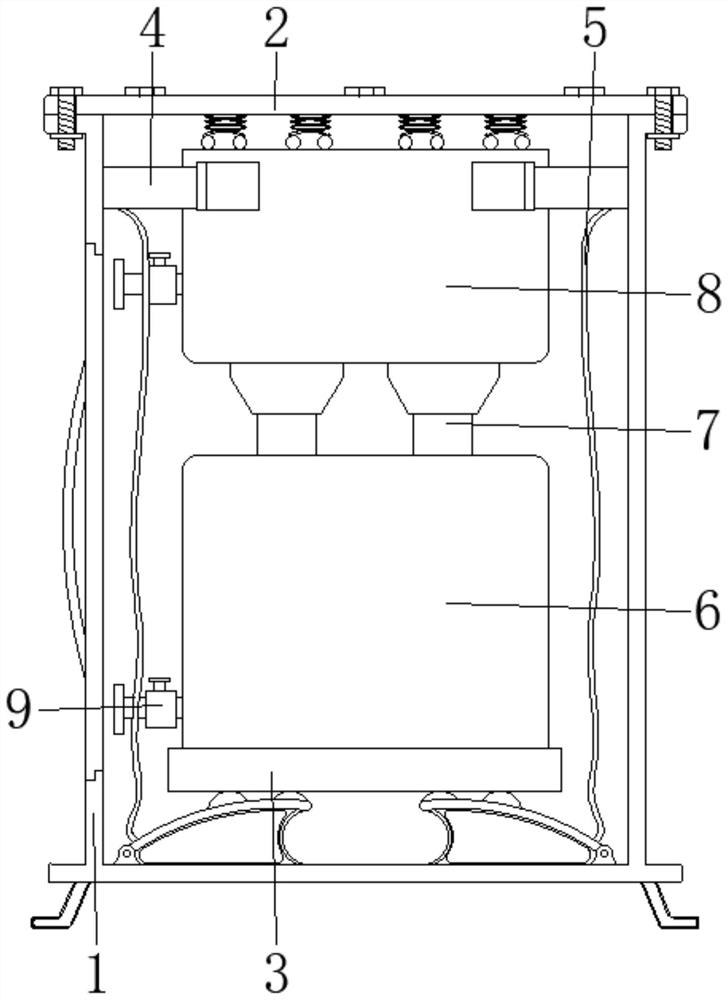

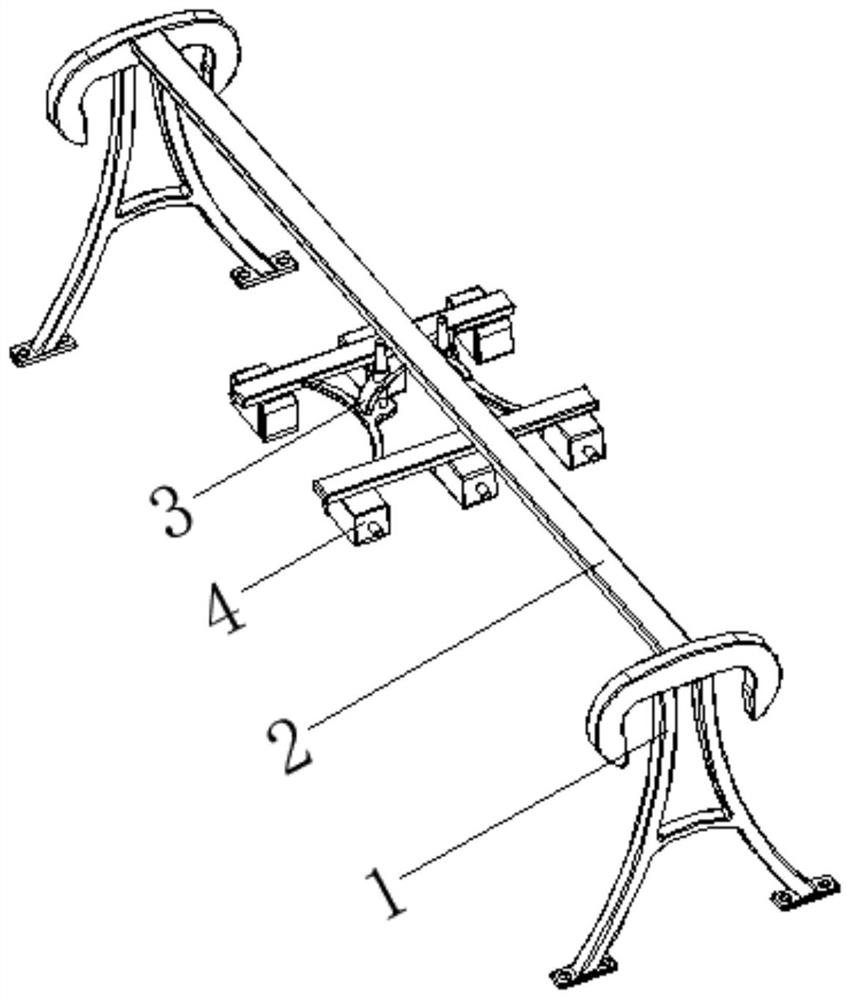

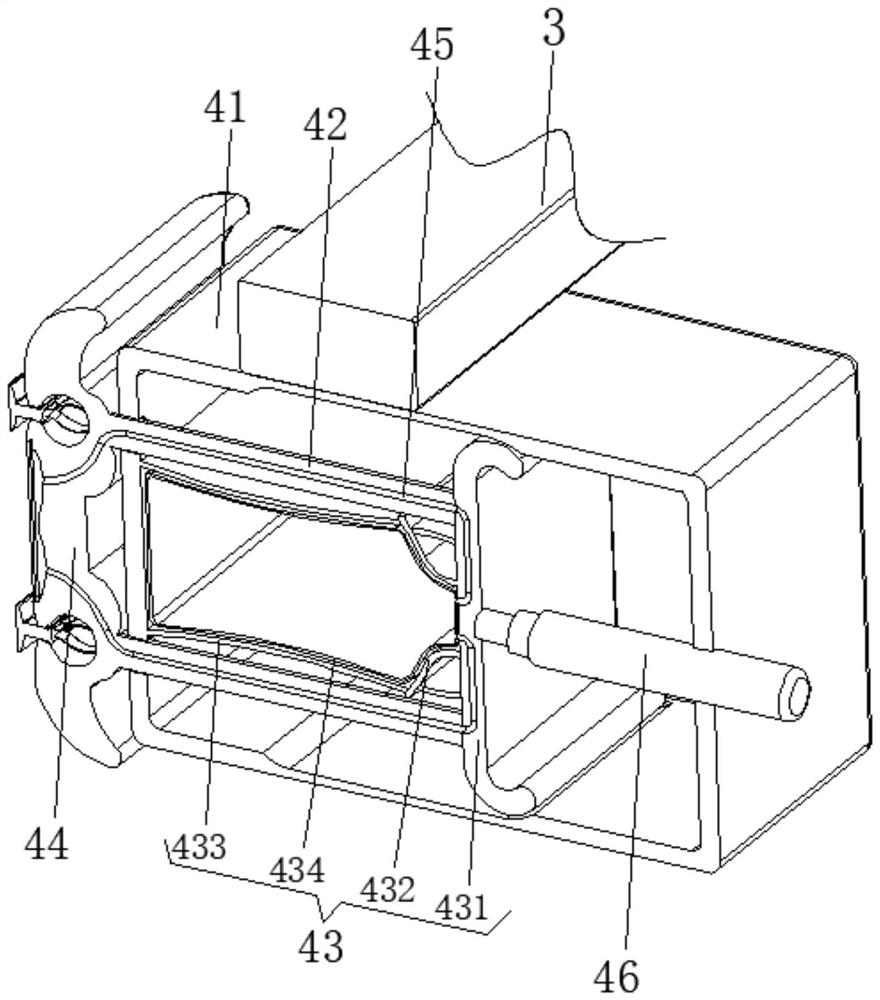

Unmanned aerial vehicle camera damping device

InactiveCN108773496AAccurate shock absorptionLess susceptible to vibrationAircraft componentsVehicle frameEngineering

The invention discloses an unmanned aerial vehicle camera damping device. The unmanned aerial vehicle camera damping device includes a vehicle frame or vehicle body, supports, an objective table, footstand brackets, a foot stand and the camera damping device; one ends of the supports are fixedly connected to an aircraft platform, and the other ends of the supports are connected to the objective table; one ends of the foot stand brackets are fixed on the lower end of the objective table, and the other ends of the foot stand brackets are fixed on a foot stand; the camera damping device includessprings, dampers, a camera installation platform and a camera; the springs and the dampers are in coaxial connection; the upper end of the camera installation platform is fixedly connected to the dampers; the upper end face of the camera installation platform is connected to the springs in a contact manner; and the lower end face of the camera installation platform is connected to the camera. Thecamera is not liable to suffer vibration caused by the rotation of rotors during flying through a simple and exquisite structure, and accurate damping on the parts needing shock absorption can be realized.

Owner:芜湖翼讯飞行智能装备有限公司

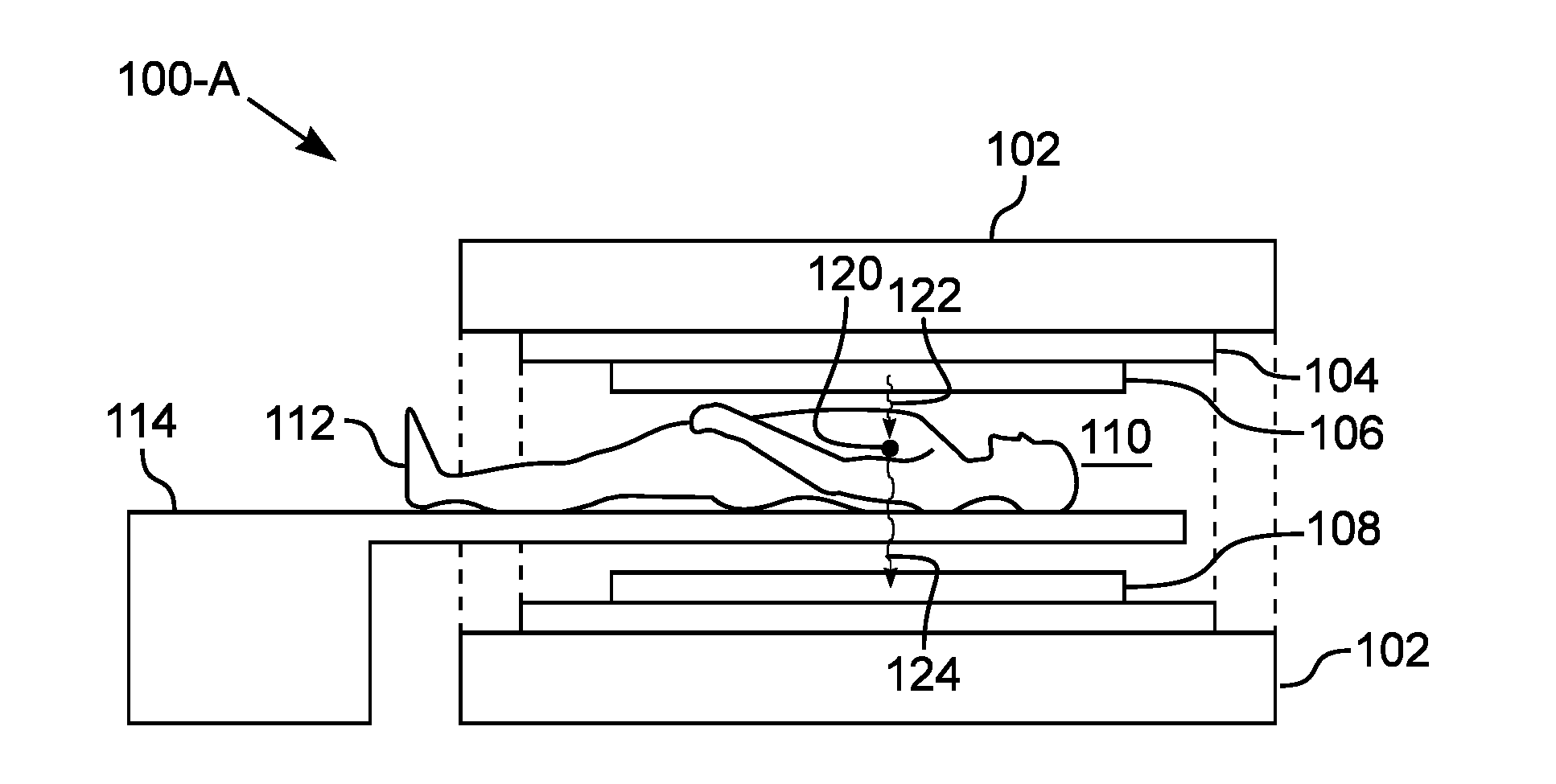

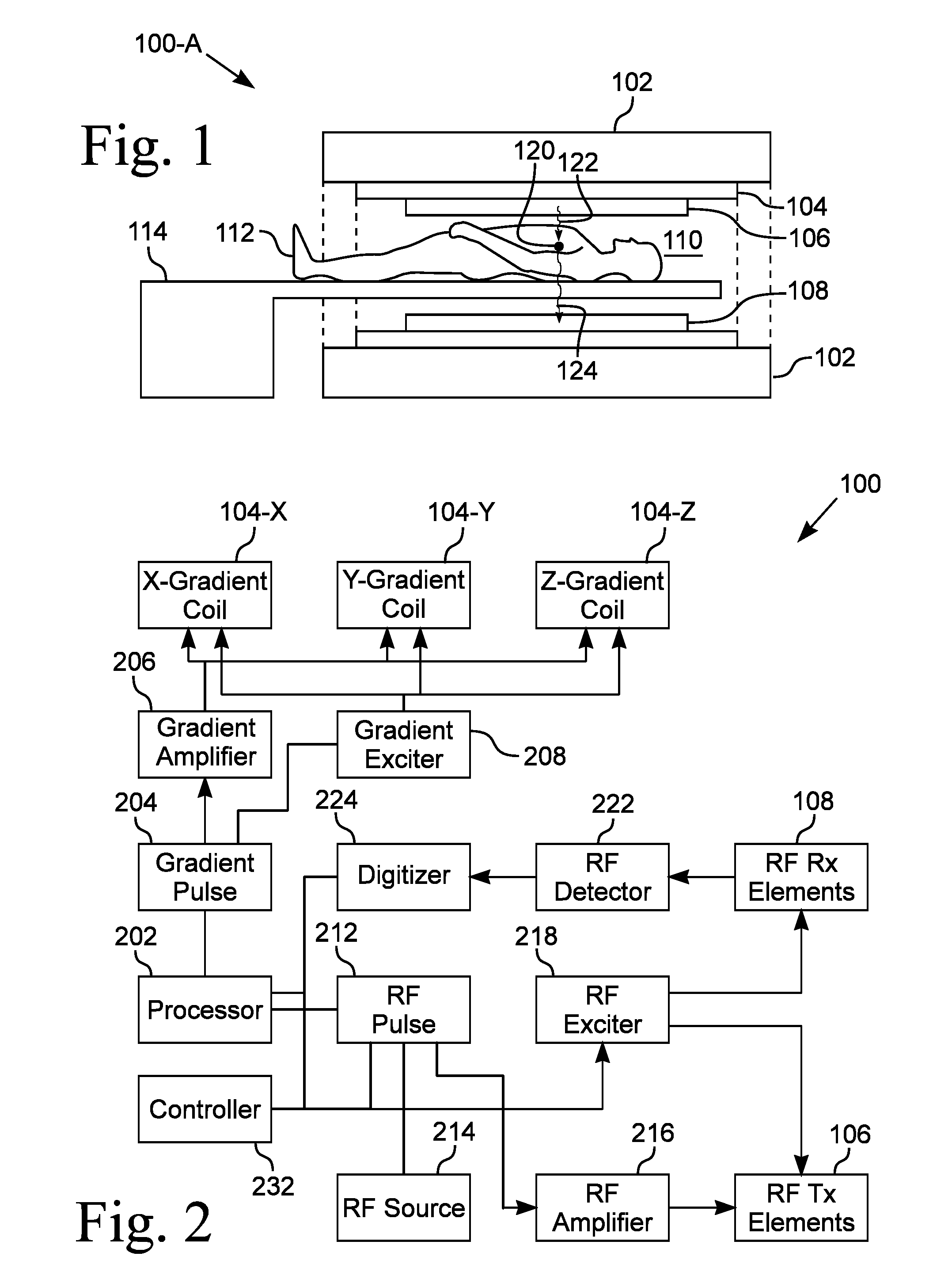

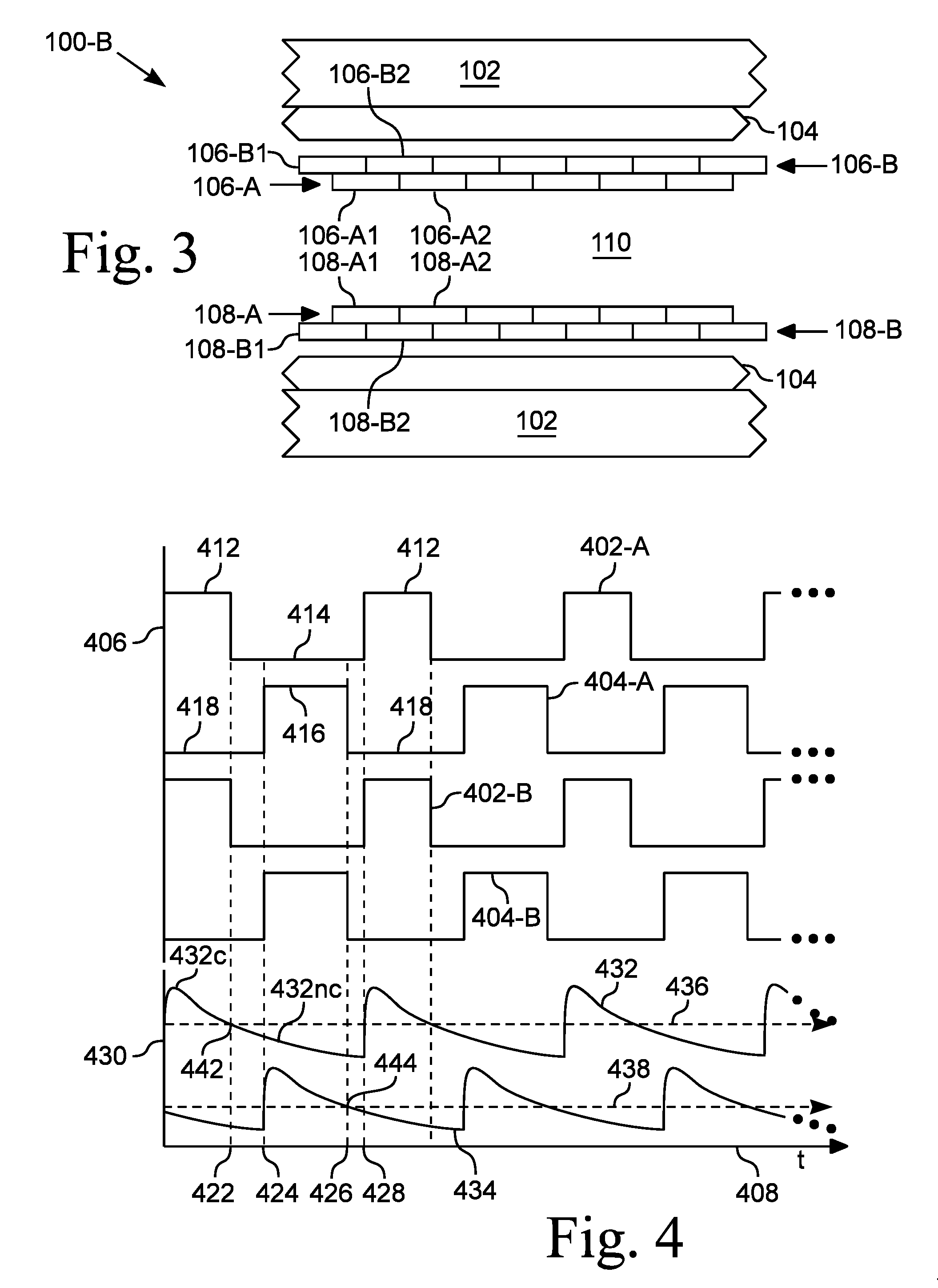

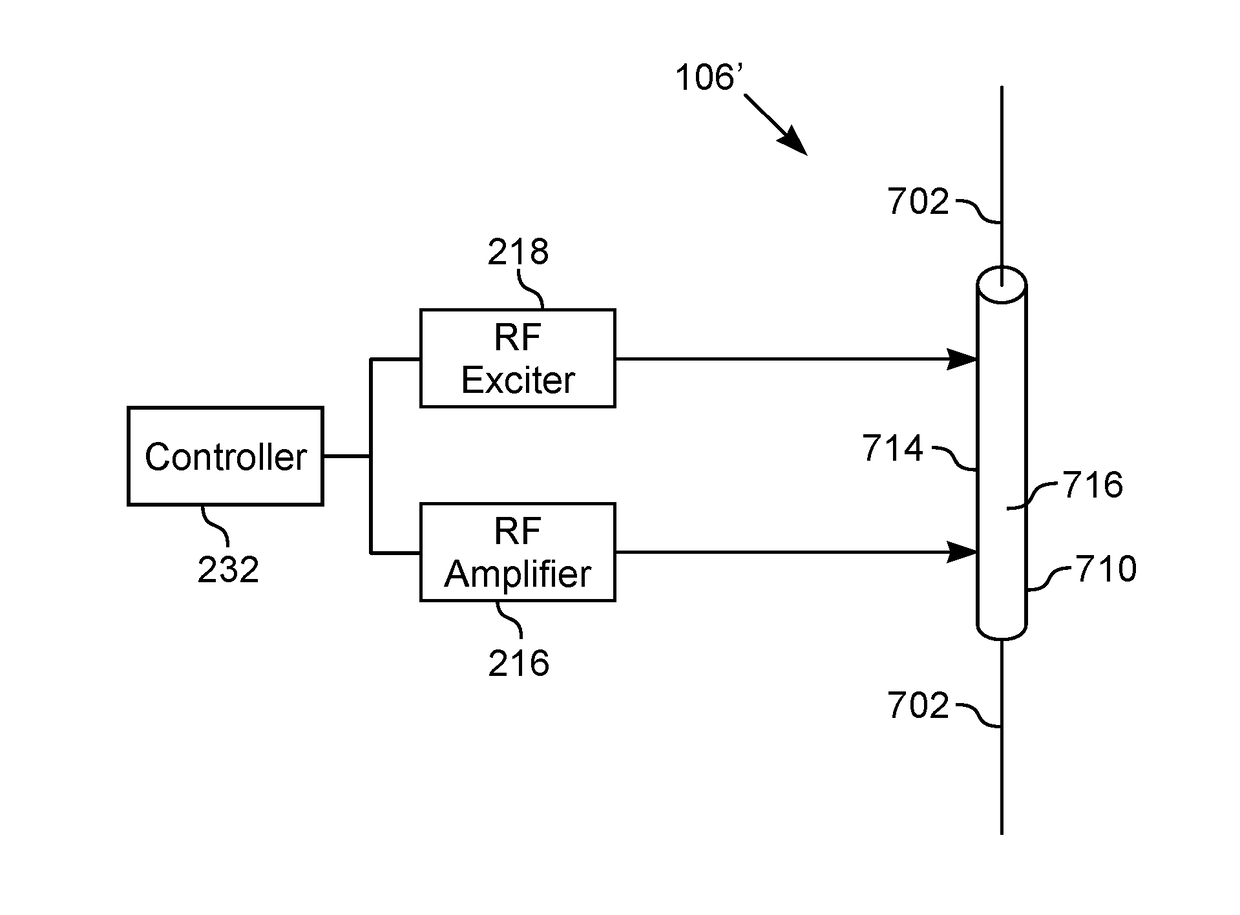

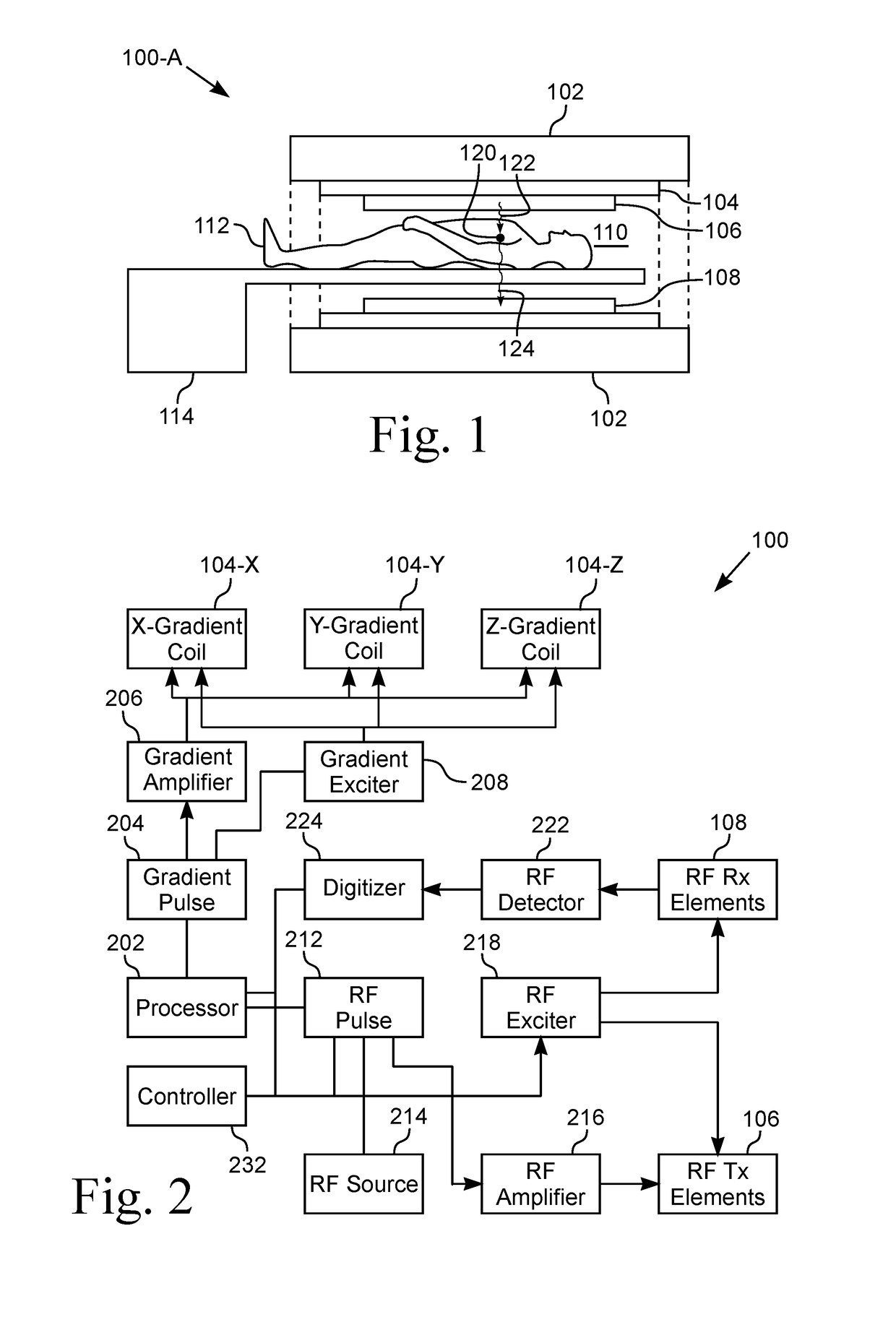

Plasma elements in medical imaging devices

InactiveUS20160370442A1Improve patient experienceImprove image qualityMeasurements using magnetic resonanceElectricityExcited molecule

Apparatus for a nuclear resonance imaging (MRI) machine that includes plasma elements. The MRI machine includes gradient coils that generate time-dependent gradient magnetic fields, transmitting elements that excite target molecules with RF energy, and receiving elements responsive to RF energy emitted by the excited molecules. The gradient coils include plasma conductors in which the plasma is ignited by an exciter. The plasma conductors are electrically connected to a gradient amplifier that outputs a signal to produce the gradient fields. The transmitting elements are plasma devices configured to emit RF energy. The receiving elements are plasma devices responsive to emitted RF energy. An RF exciter selectively and alternatingly ignites said plasma devices to avoid coupling and interference between them.

Owner:ANDERSON THEODORE R

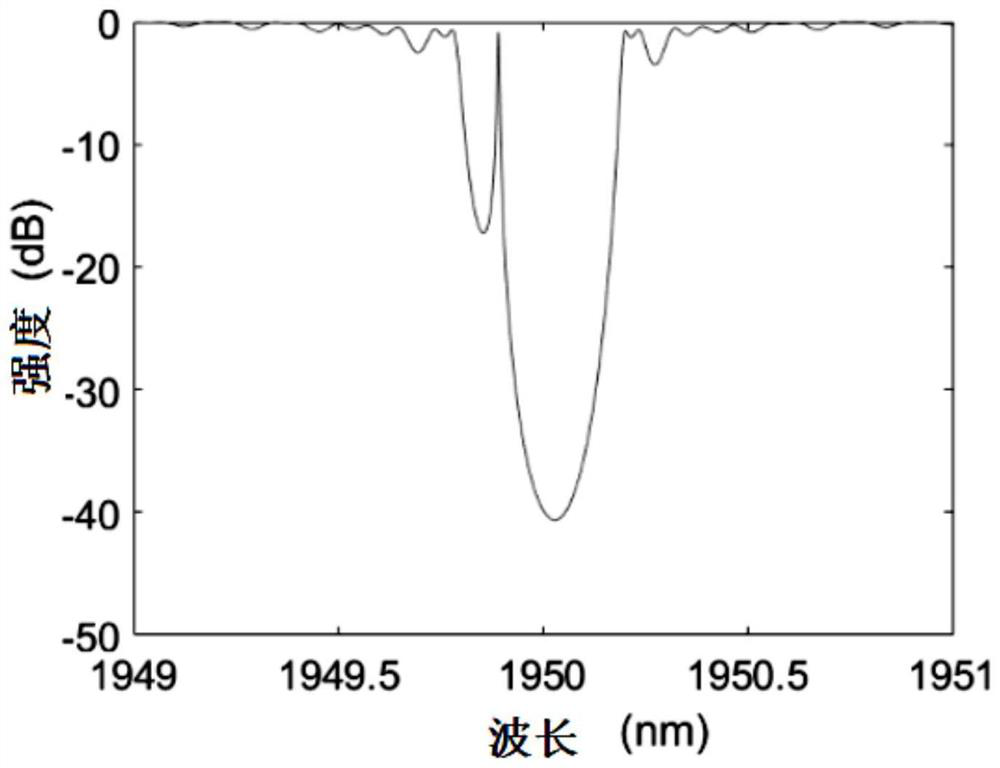

Narrow-linewidth single-frequency thulium-doped distributed feedback fiber laser and system

PendingCN113922195ALess susceptible to interferenceNot susceptible to temperatureLaser arrangementsActive medium shape and constructionGratingLine width

The invention relates to the technical field of optical signals, in particular to a narrow-linewidth single-frequency thulium-doped distributed feedback fiber laser and system. The narrow-linewidth single-frequency thulium-doped distributed feedback fiber laser comprises a thulium-doped fiber, a fiber bragg grating with phase shift is preset, the thulium-doped fiber is used for receiving a pump light signal, and when the pump light signal is transmitted to the phase shift grating, the phase shift grating forms laser oscillation based on the pump light signal and outputs a single-frequency laser signal; and the wavelength division multiplexer is arranged on a single-frequency laser signal output optical path track and is used for receiving the optical signal and outputting the optical signal to the phase shift grating, or is used for receiving the single-frequency laser signal and outputting the single-frequency laser signal along the single-frequency thulium-doped distributed optical fiber.

Owner:SHANGHAI PRECILASERS TECH CO LTD

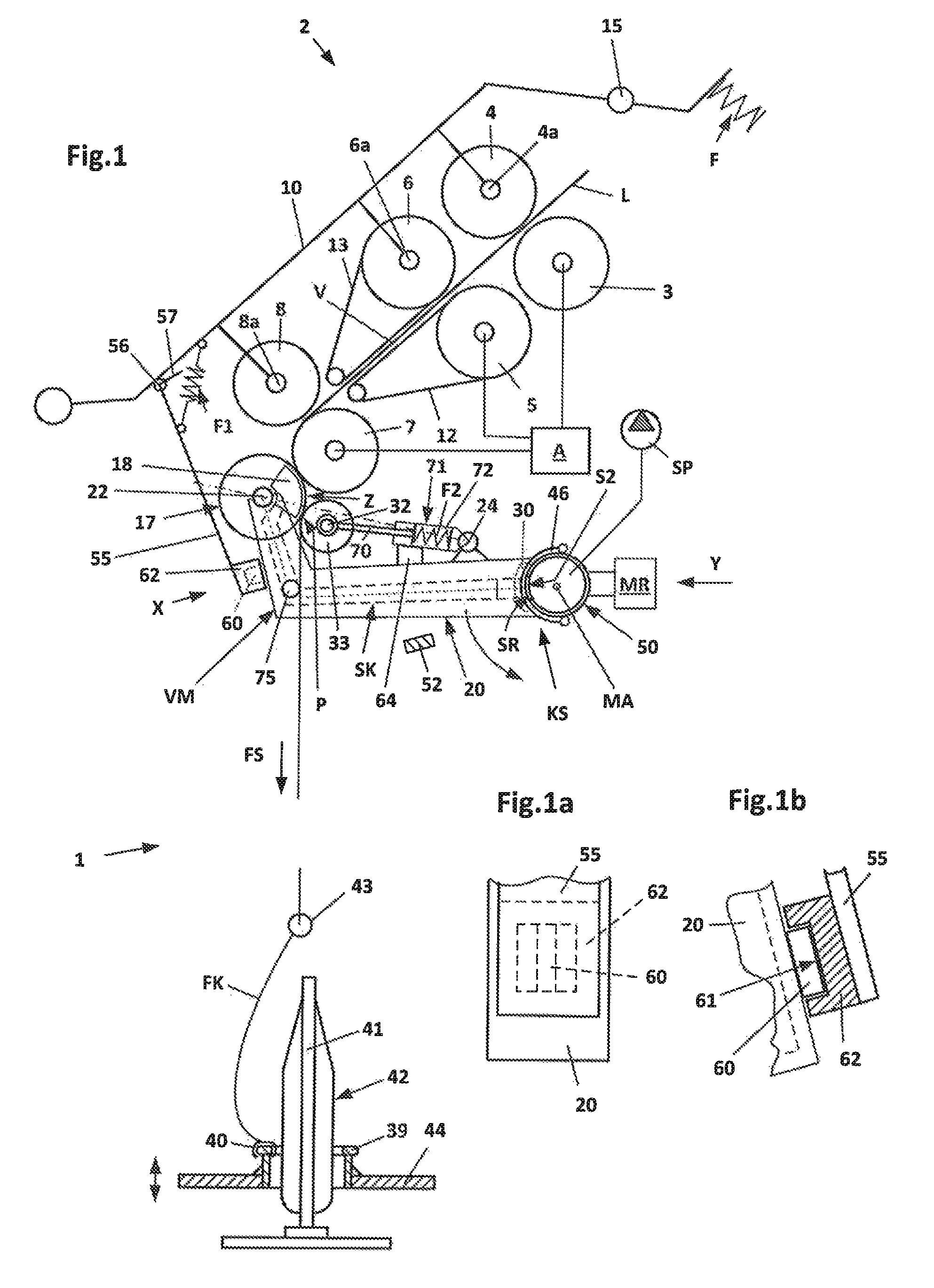

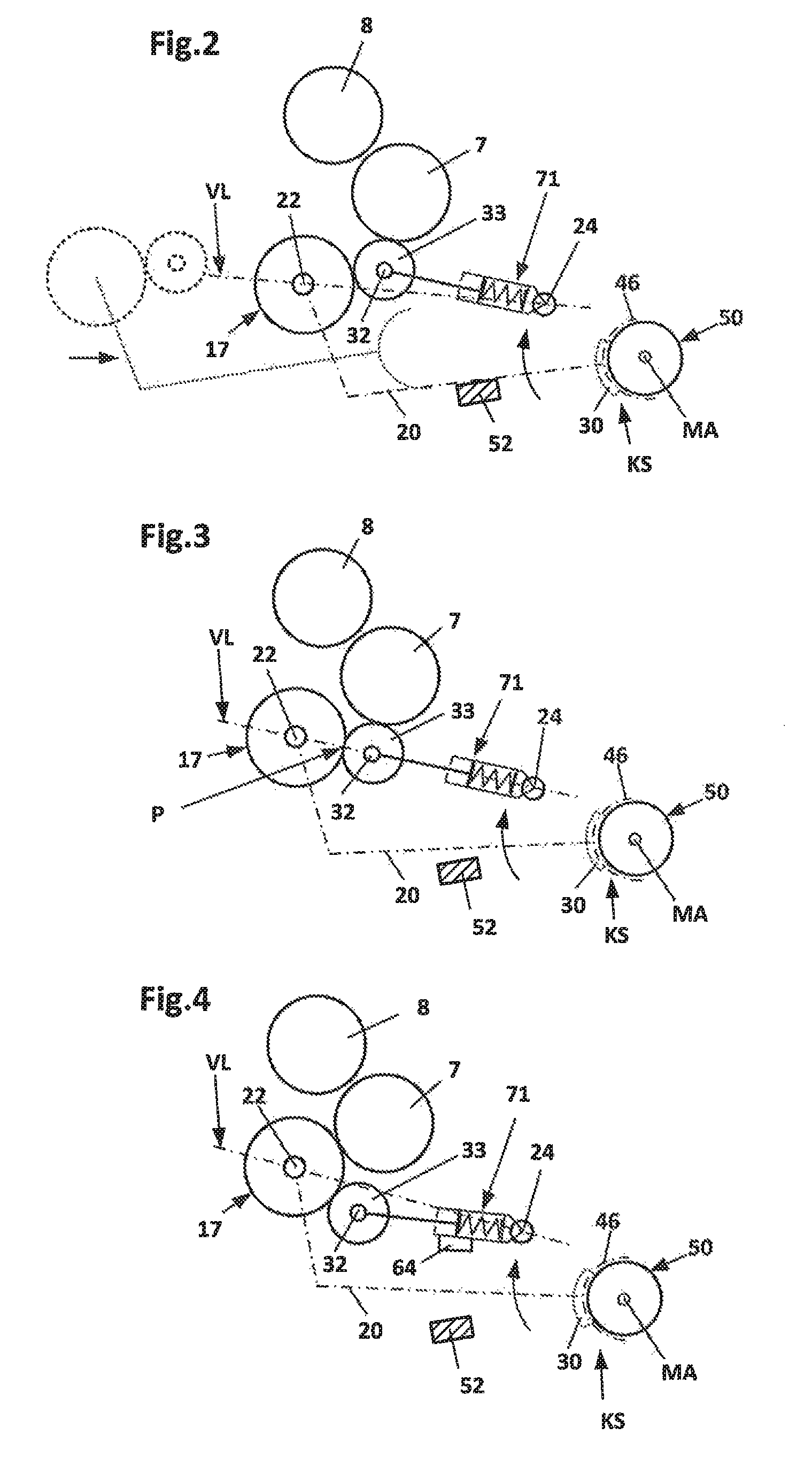

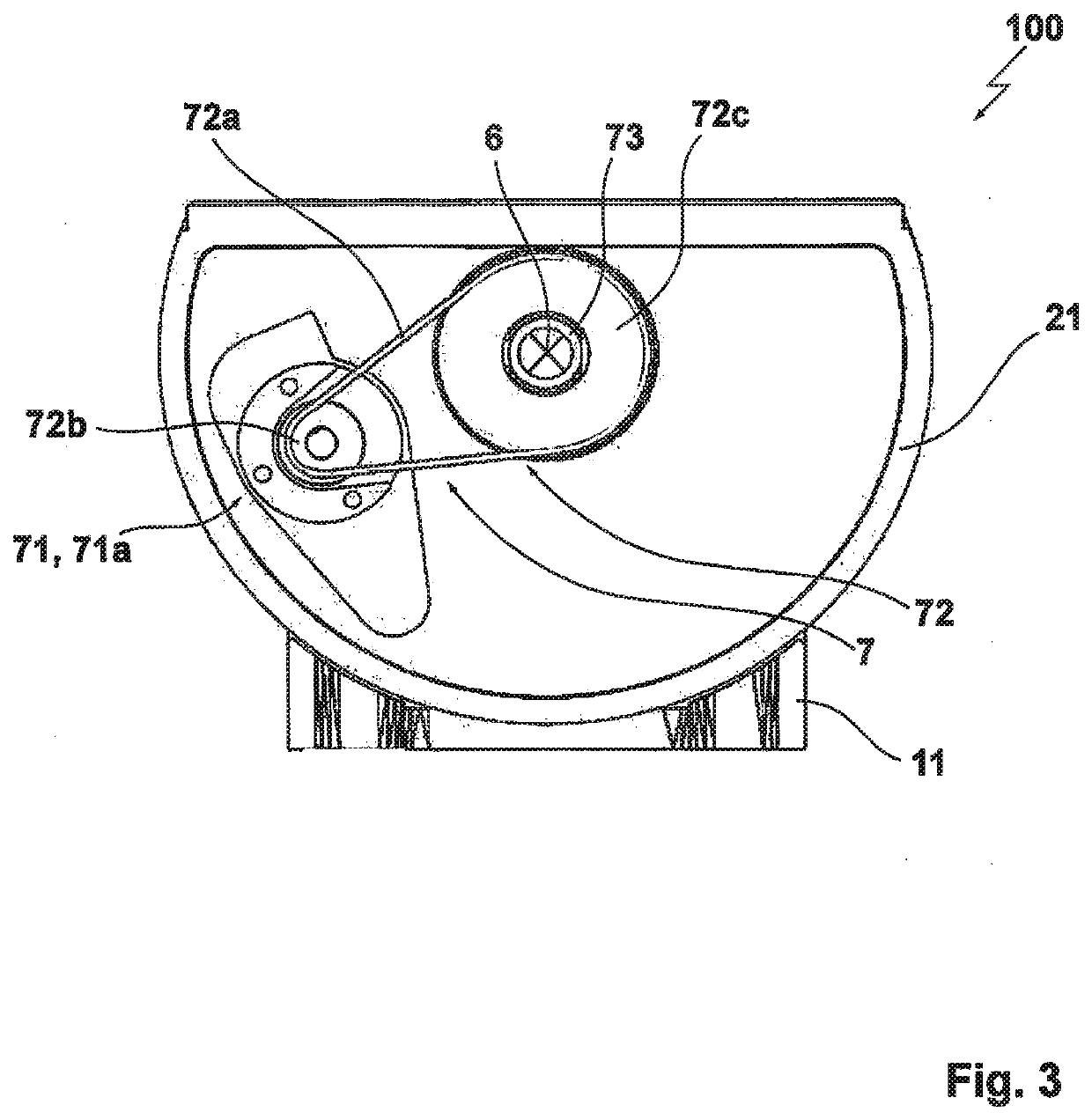

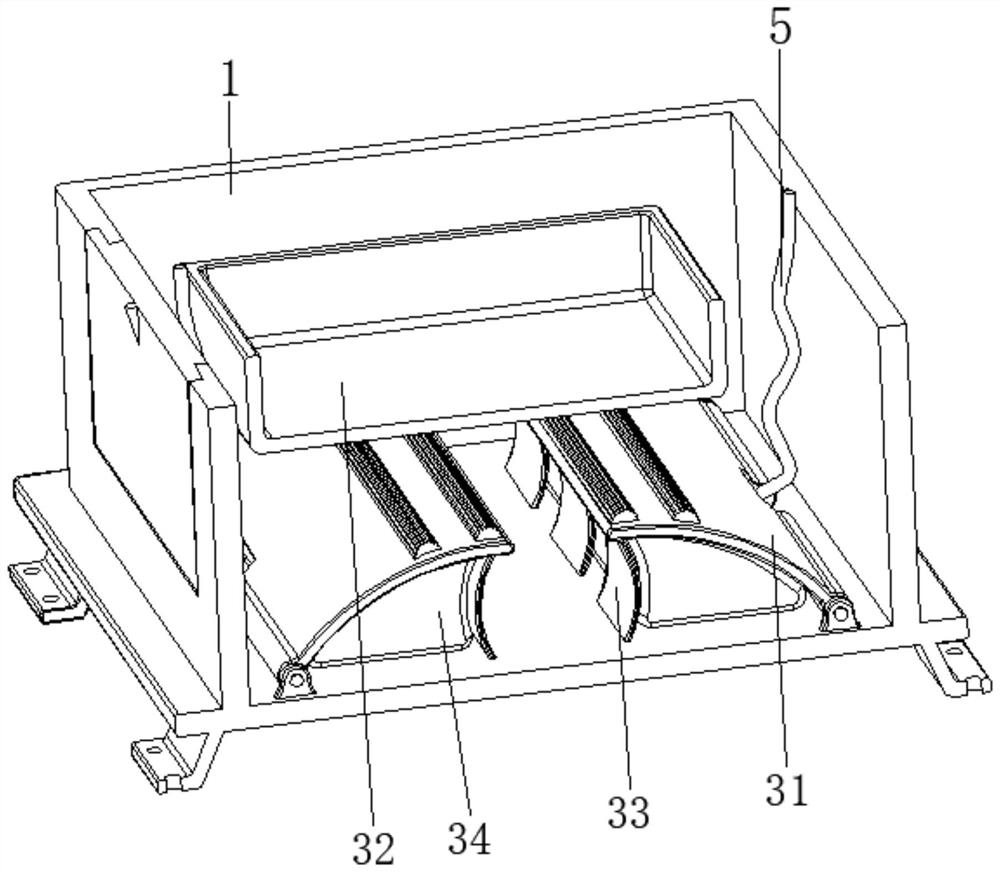

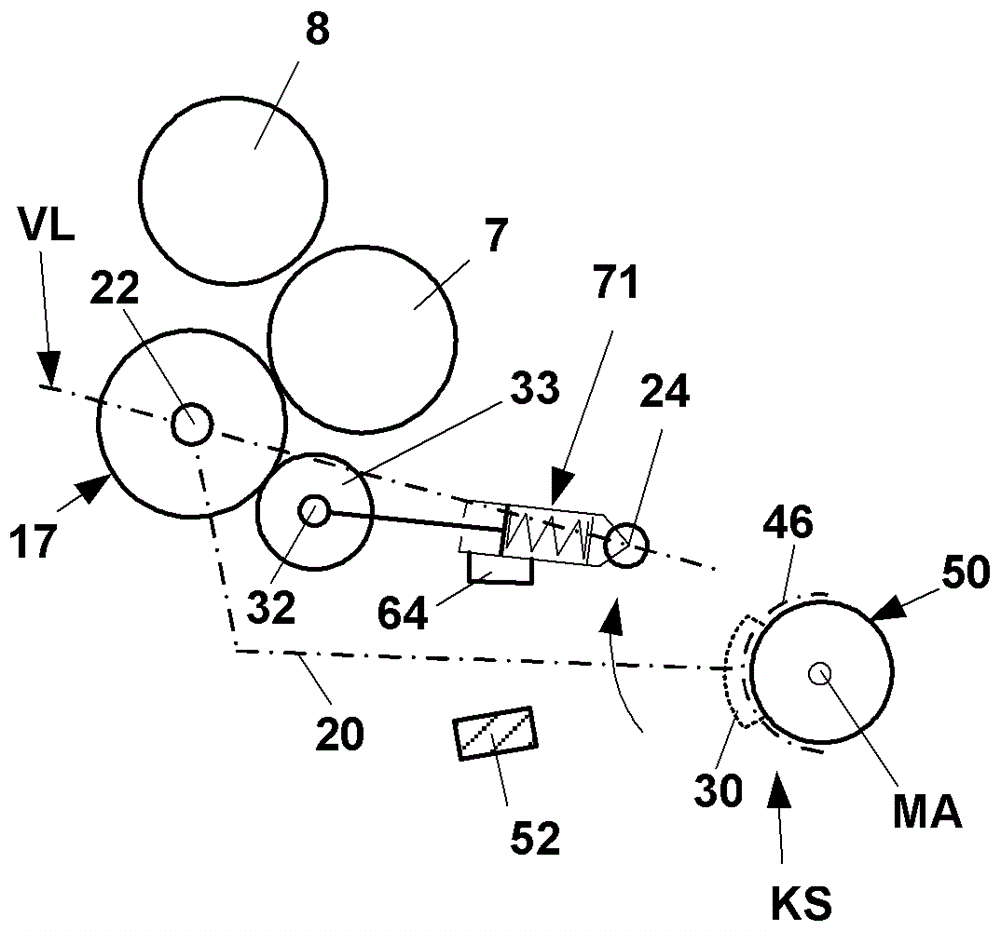

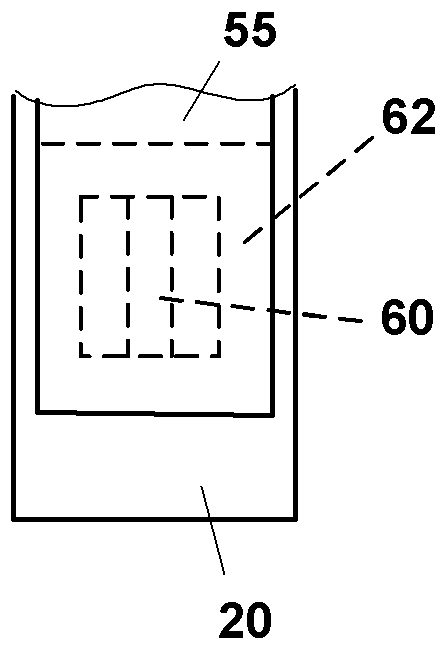

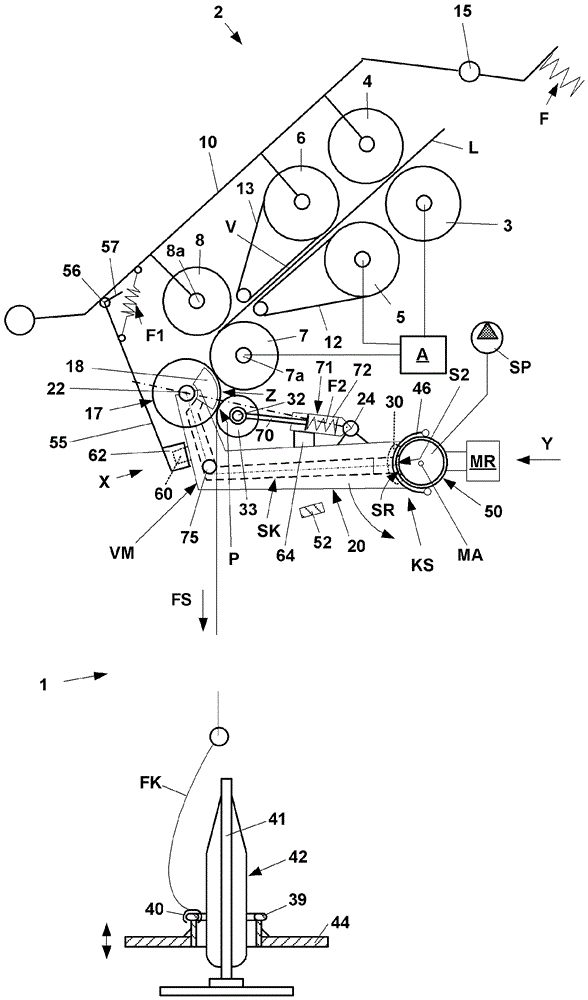

Spinning machine having a compaction device

ActiveUS9353464B2Less susceptible to vibrationEasy and quick operabilityDrafting machinesContinuous wound-up machinesRotational axisEngineering

A device for compacting a fiber composite on a spinning machine includes consecutive drafting arrangement roller pairs. A compaction unit is pivotably mounted on the machine frame downstream of the delivery roller pairs with a pivot axis parallel to the rotational axes of the delivery roller pair, and includes a support with a suction drum rotatably supported on the support. At the end of a suction zone of the drum, a nip roller is fastened to the support to form a nip line. The support is spring-loaded to form a drive connection between the lower roller of the delivery roller pair and the suction drum, wherein the suction drum is moved against the lower roller. Guide means fix the compaction unit in position as mounted on the machine frame, and the spring element is mounted on the free end of the pressure lever.

Owner:MASCHINENFABRIK RIETER AG

Method and apparatus for tracking servo control of an optical disc playback apparatus

InactiveUS7551528B2Less susceptible to vibrationCombination recordingRecord information storageOptical pickupEngineering

An optical disc playback apparatus includes an optical pickup, an RF amplifier that generates a tracking error (TE) signal based on an electrical signal from the optical pickup, a defect detector that detects a defect on the optical disc and that outputs a DFCT signal indicating the detected defect, a switch that outputs a hold signal when a defect is detected based on the DFCT signal, a driver that controls the optical pickup based on the output signal of the switch, a corrector that extracts an oscillation component of the optical pickup from the TE signal in response to the DFCT signal when a defect is detected and that outputs a correction signal indicating the oscillation component, and an adder that adds the correction signal from the corrector to the hold signal.

Owner:ALPINE ELECTRONICS INC

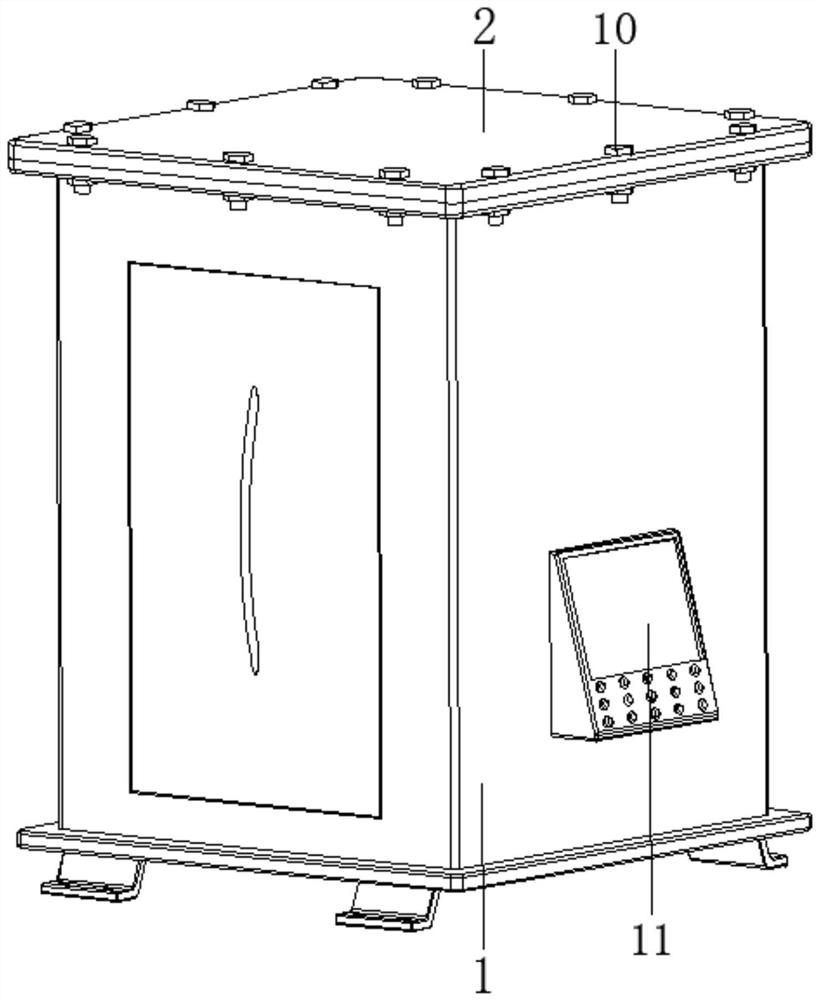

Mathematical teaching model and using method

InactiveCN110491195AStable structureLess susceptible to vibrationEducational modelsElectrical appliancesPiston rodMagnet

The invention discloses a mathematical teaching model and a using method. The mathematical teaching model includes a base, limit levers, a first air cylinder, a first piston rod, a fixing plate, chutes, fixing seats, mobile wheels, through holes, fixed pins, pin holes, a support frame, side plates, a support plate, a first magnet, a second magnet, spring seats, first springs, extrusion boards, second springs, support inner barrels, support sleeves, rubber mats, a cabinet body, an electrical box, a main spare power supply, storage areas, a lifting box, second air cylinders, second piston rods,a teaching platform, a display screen, a camera, an operation panel, a servo motor and a placing plate. The first air cylinder is welded on the top of the inner wall of the base, an output end of thefirst air cylinder is fixedly connected with the fixing plate through the first piston rod, and the limit levers are arranged on two corresponding ends at one side of the inner wall of the base and penetrate through the fixing plate. The mathematical teaching model has the advantages of being good in direct viewing effect, convenient to display and move, high in teaching quality, stable in structure, and not liable to be affected by vibration.

Owner:李茗洲

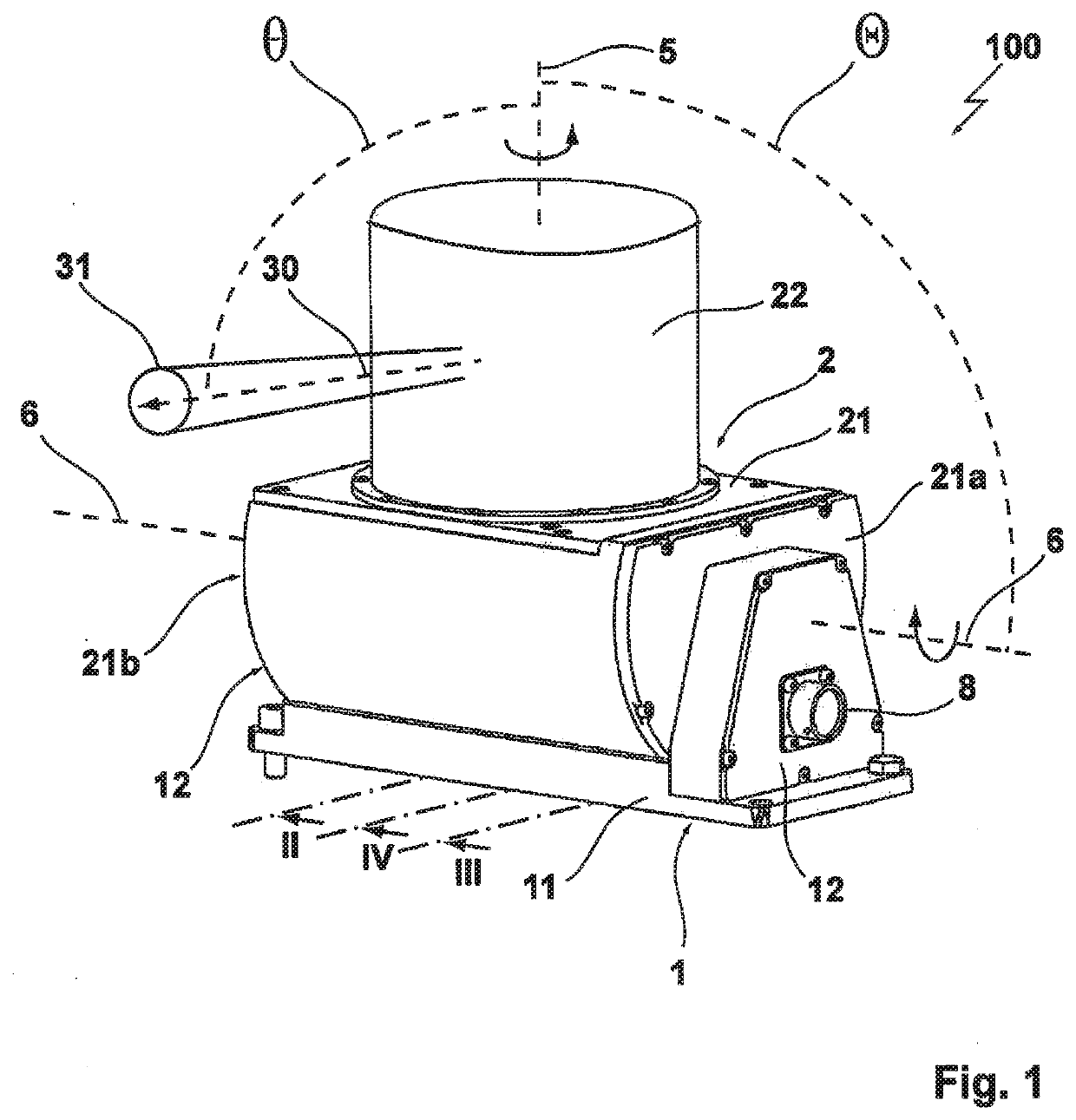

Radar sensor

ActiveUS20200158818A1Less susceptible to interferenceCompact designRadiating element housingsRadio wave reradiation/reflectionRadarElectrical and Electronics engineering

A radar sensor having a frame, a housing arranged at the frame, a transmission and reception unit for high frequency signals arranged within the housing, wherein a radiation direction of the high frequency signals irradiated by the transmission and reception unit is rotatable about an axis of rotation. The radiation direction of the high frequency signals irradiated by the transmission and reception unit is substantially orthogonally oriented toward the axis of rotation, and the housing is supported at the frame rotatably about a pivot axis.

Owner:INDURAD

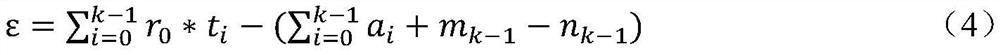

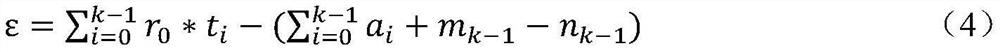

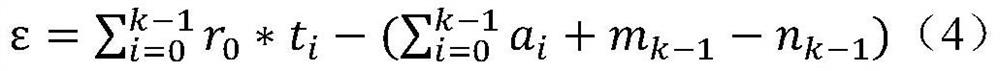

Uniform mixing production process control method

ActiveCN113156818AHigh precisionImprove working conditionsAdaptive controlProcess engineeringIndustrial engineering

The invention discloses a uniform mixing production process control method, and belongs to the technical field of ore blending. The method provided by the invention comprises the following steps: 1, obtaining a tank adding amount a, an initial in-bin material amount m, a period end material amount n, a batching amount c, a batching rate r and a theoretical batching rate r0 within an adjustment period t in a uniform mixing process; 2, determining a relative error between quantitative feeding equipment and a hopper scale, and calculating an absolute error in a mixing period; 3, introducing metering data of a tank adding scale, and compensating and correcting errors of the quantitative feeding equipment; and 4, obtaining correction data, and adjusting the discharging process of the quantitative feeding equipment in each period. According to the invention, error correction is carried out on the data collected by the quantitative feeding equipment by introducing the metering data of the tank adding scale, so that the obtained feeding amount is closer to a real value, and the batching precision of the uniform mixing system is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Slide rails with self-locking function

The invention provides a sliding rail with a self-locking function, which can solve the problems that the service life of a lock catch is short because of long-term use impact and the sealing performance of an electrical appliance is poor in the kitchen electrical appliance which is provided with a pulling basket drawer. The sliding rail with the self-locking function comprises a fixed guide rail and a movable guide rail; the movable guide rail is mounted on the fixed guide rail in a sliding manner; a sliding rail door plate bracket is mounted at the front end of the movable guide rail; the sliding rail door plate bracket is fixed and connected to a pulling basket drawer door plate; the fixed guide rail is fixedly mounted on a liner frame of the electrical appliance; an electromagnetic locking system is mounted on the side surface, which faces the liner wall of the electrical appliance, of the rear end part of the fixed guide rail; a pin hole is formed in the top surface of the rear end of the movable guide rail; the electromagnetic locking system can act when the fixed guide rail and the movable guide rail are positioned in a closed position so as to realize the locking or unlocking between the electromagnetic locking system and the pin hole.

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

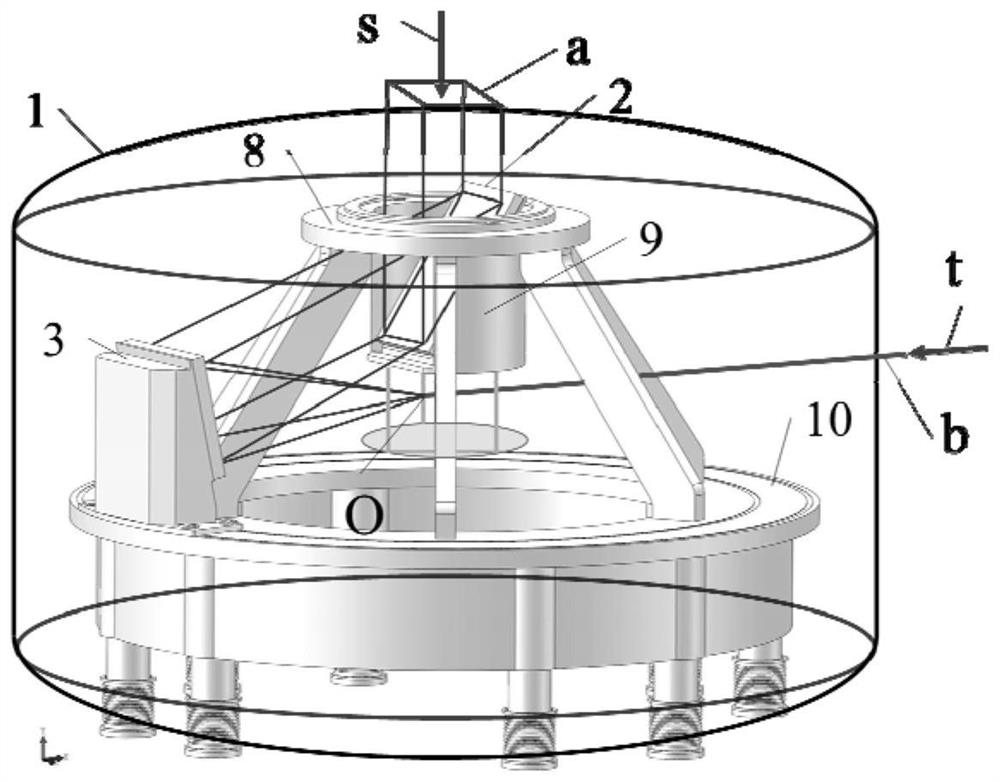

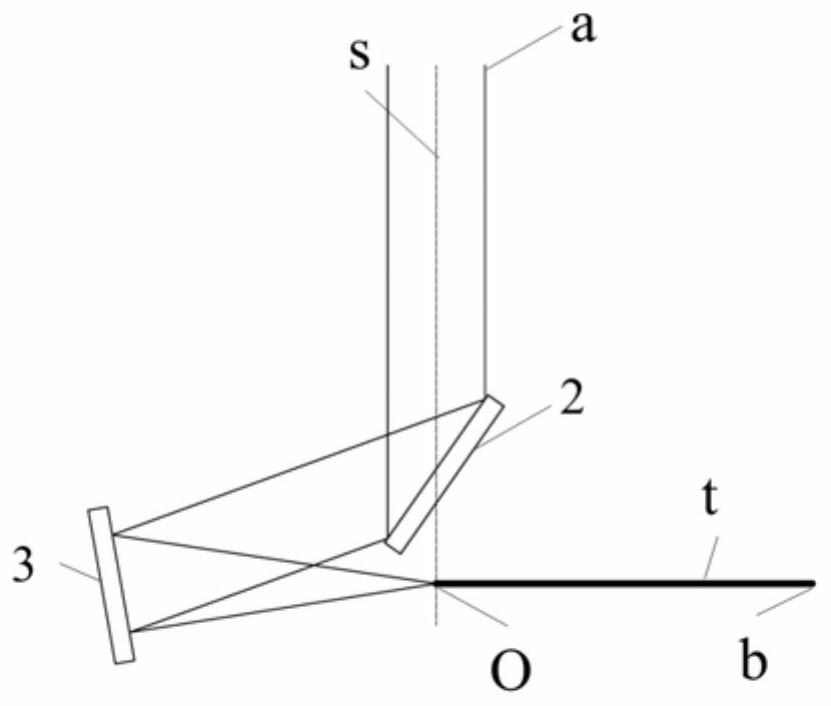

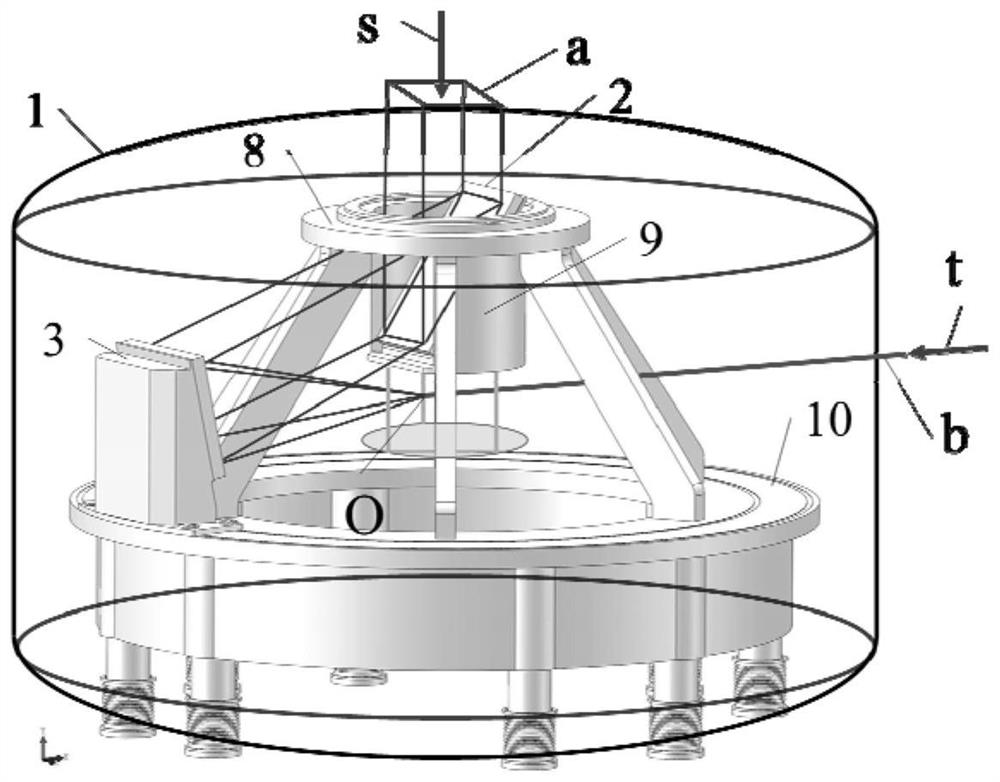

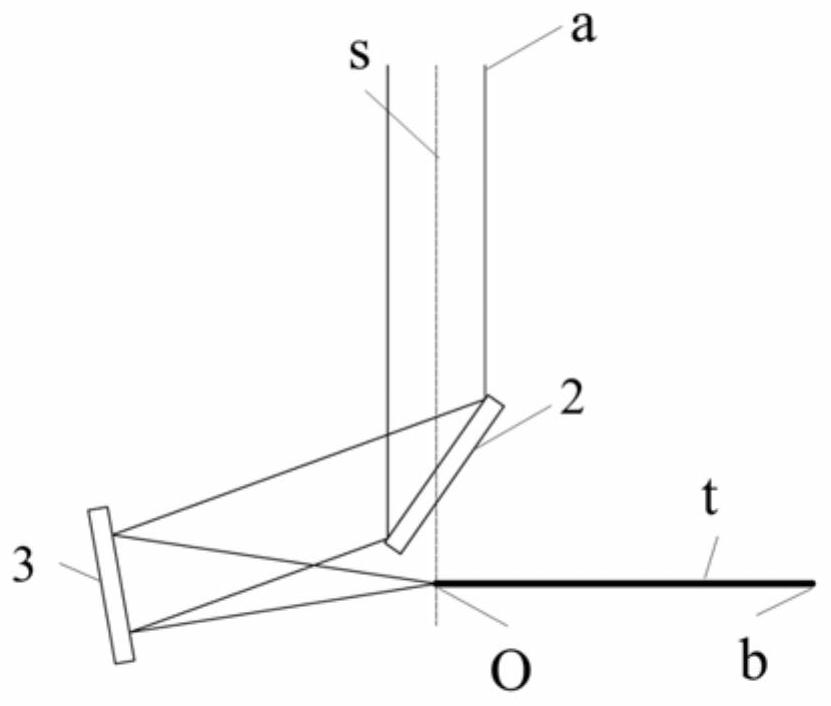

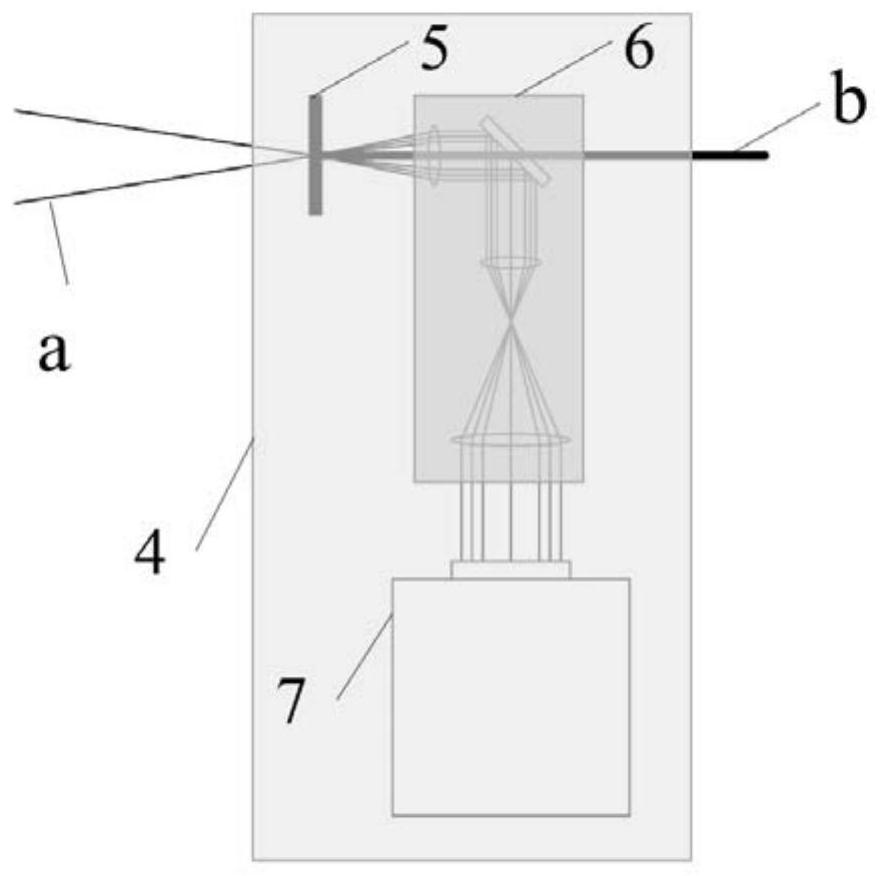

Laser Focus Adjustment System Realizing 360° Interaction with Oriented Beamlines

A laser focus adjustment system that realizes 360-degree interaction with a directional beamline, including a focus optical path, a focal spot detection and alignment system, and a vacuum cavity. In the present invention, the laser initially propagates vertically from top to bottom, the optical axis is s, the directional beamline propagates along the horizontal direction, the central axis is t, and the axes s and t intersect at point O (fixed laser focal spot position). The present invention utilizes plane mirror (reflection angle is M, 45 °

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A kind of mixing production process control method

The invention discloses a method for controlling a mixing production process, which belongs to the technical field of ore blending. The method of the present invention comprises the following steps: step 1, obtaining the slotting amount a, the initial material volume m in the warehouse, the cycle-ending material volume n, the batching amount c, the batching rate r and the theoretical Batching rate r 0 Step 2, determine the relative error of the quantitative feeding equipment and the hopper scale, and calculate the absolute error in the mixing cycle; Step 3, introduce the measurement data of the slotting scale, and compensate and correct the error of the quantitative feeding equipment; Step 4, Obtain correction data to adjust the feeding process of the dosing equipment every cycle. The invention introduces the metering data of the slotting scale to correct the error of the data collected by the quantitative feeding equipment, so that the obtained feeding amount is closer to the real value, and the batching accuracy of the mixing system is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

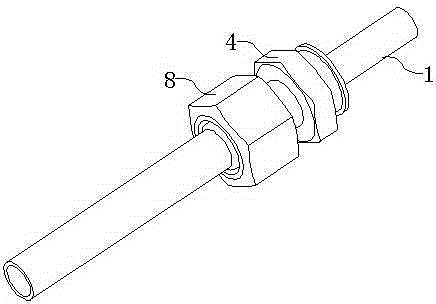

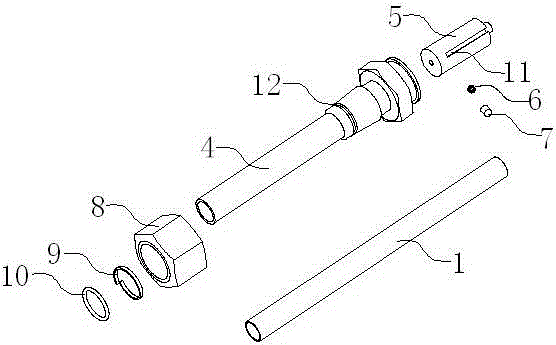

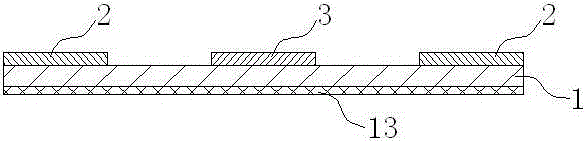

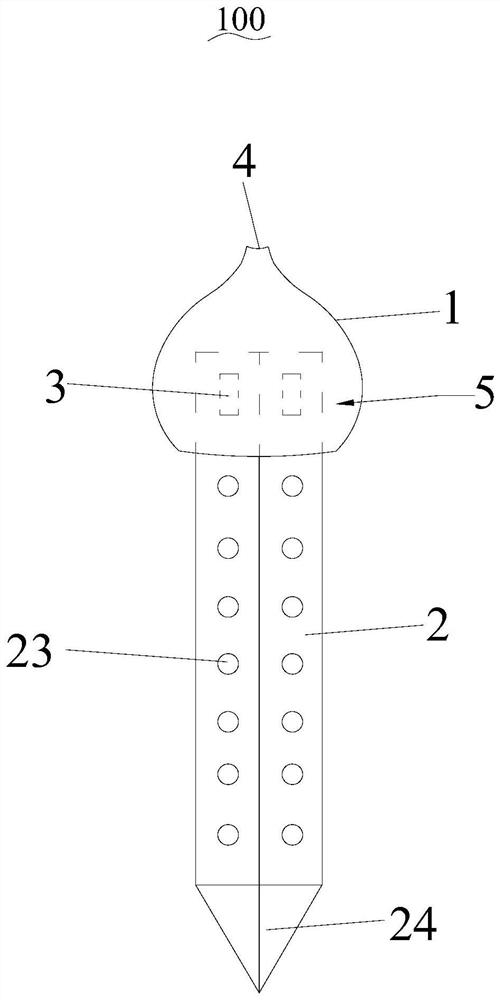

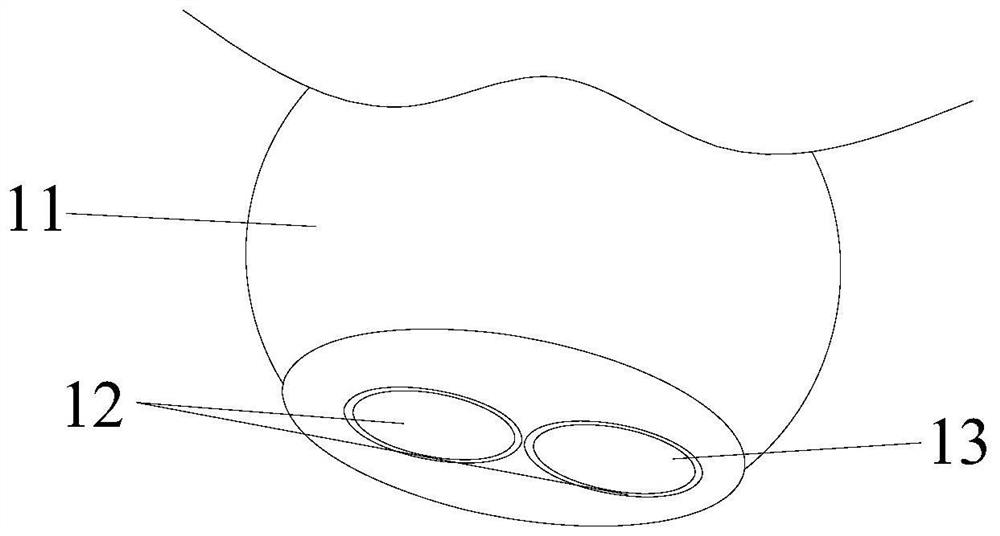

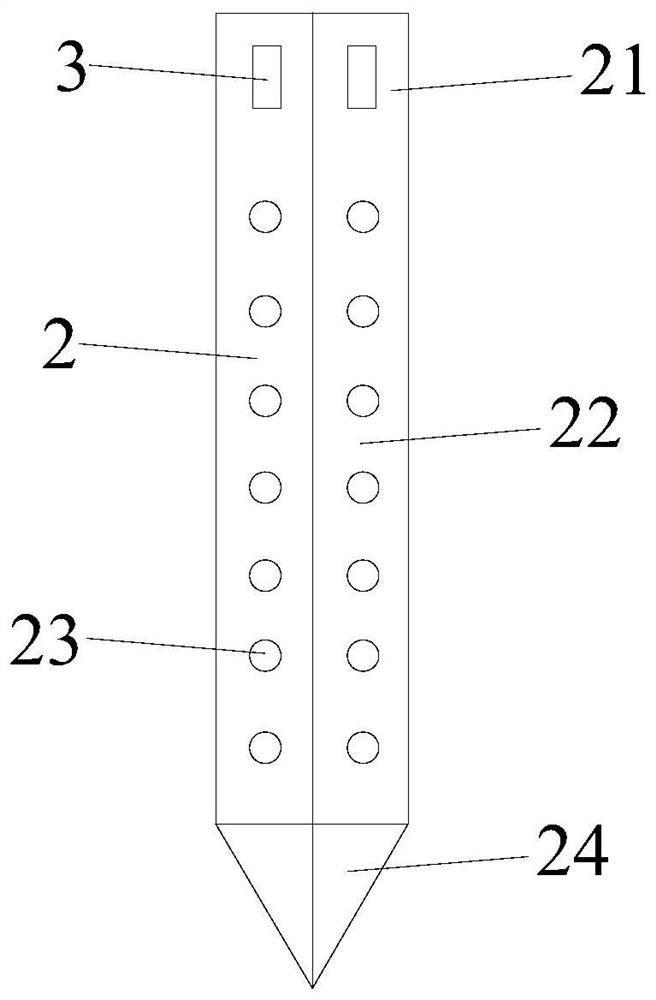

A thermal flow sensor probe

Owner:EMA PRECISION ELECTRONICS SUZHOU

Concentration and crystallization device for N-methylformamide

ActiveCN114452674ANot easy to interfereReduce random movementSolution crystallizationCrystallization by component evaporationMechanical engineeringMethyl palmoxirate

The N-methylformamide concentration and crystallization device comprises a machine body, an elastic pressing device, a buffering device, a limiting device and a connecting hose, the elastic pressing device is arranged at the top of the machine body, the buffering device is arranged at the bottom of the inner wall of the machine body, and the limiting device is arranged on the inner wall of the machine body and is close to the top; the arc-shaped elastic piece is fixed between the end of the hold-down device and the two corresponding sides of the bottom of the inner wall of the machine body, the expansion air bag is arranged between the bottom of the hold-down device and the two corresponding sides of the bottom of the inner wall of the machine body and is close to the arc-shaped elastic piece, and an air port of the expansion air bag is communicated with the bottom end of the connecting hose. The concentration and crystallization device for N-methylformamide achieves the effect of buffer protection, can perform elastic contact and buffer protection, is not easily influenced by external force or vibration, is good in overall stability, is not easy to interfere with the concentration and crystallization process, is safe and reliable, and improves the working efficiency and the use performance.

Owner:SUQIAN XINYA TECH

Structure for mounting boring cutter in embedding manner

The invention discloses a structure for mounting a boring cutter in an embedding manner. The structure comprises a cutter bar, wherein a block-shaped cutter holder is mounted at the front end of the cutter bar in a screwing manner; a locking sleeve is mounted on the outer wall of the cutter bar in a screwing manner; the front end surface of the locking sleeve is propped against the cutter holder; the lower right corner of the cutter holder is cut into an oblique plane; a triangular installation hole extending into the cutter holder is formed in the oblique plane; the boring cutter is inserted into the installation hole in the embedding manner; a locking hole opposite to the installation hole of the boring cutter is formed in the front end surface of the cutter holder; a locking bolt is screwed in the locking hole; and the front end of the locking bolt is propped against the boring cutter. According to the structure, the structural design is novel; the locking sleeve guarantees the firm connection between the cutter bar and the cutter holder; and the boring cutter is mounted in the cutter holder in an embedding manner, so that the stability is improved, influence caused by vibration can be avoided easily, and the mechanical processing accuracy is greatly improved.

Owner:HEFEI HONGQIANG METALLURGICAL TECH

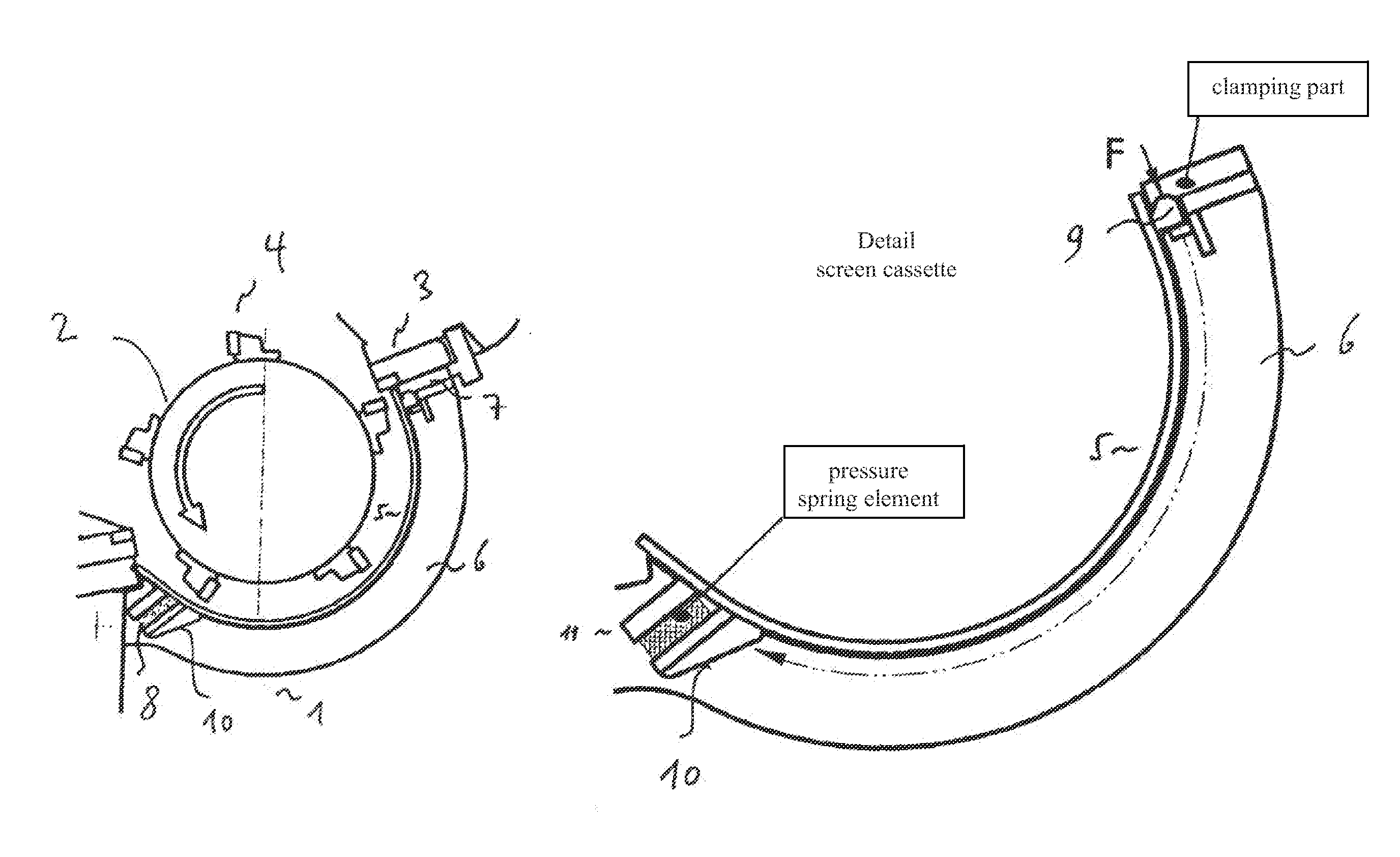

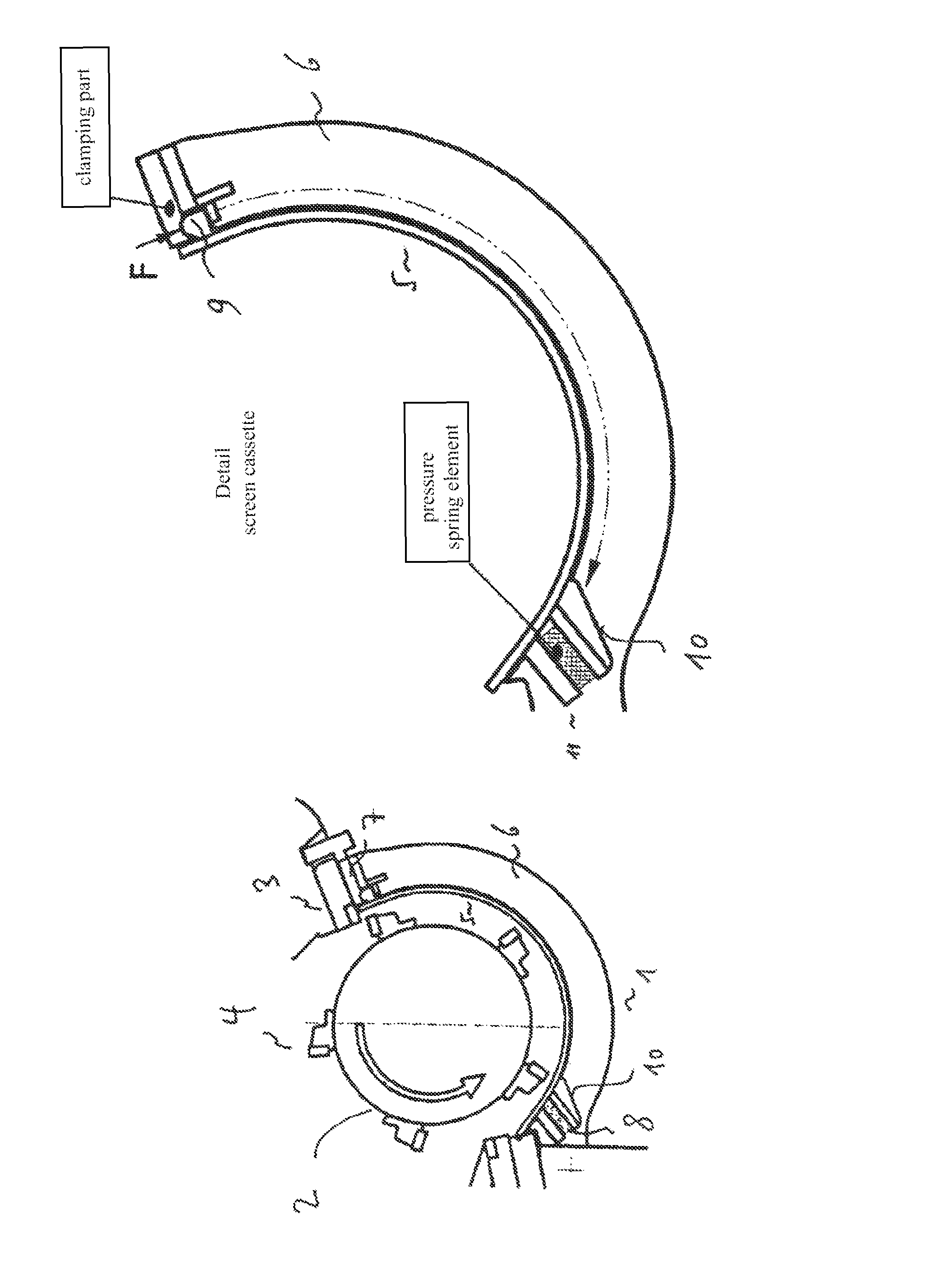

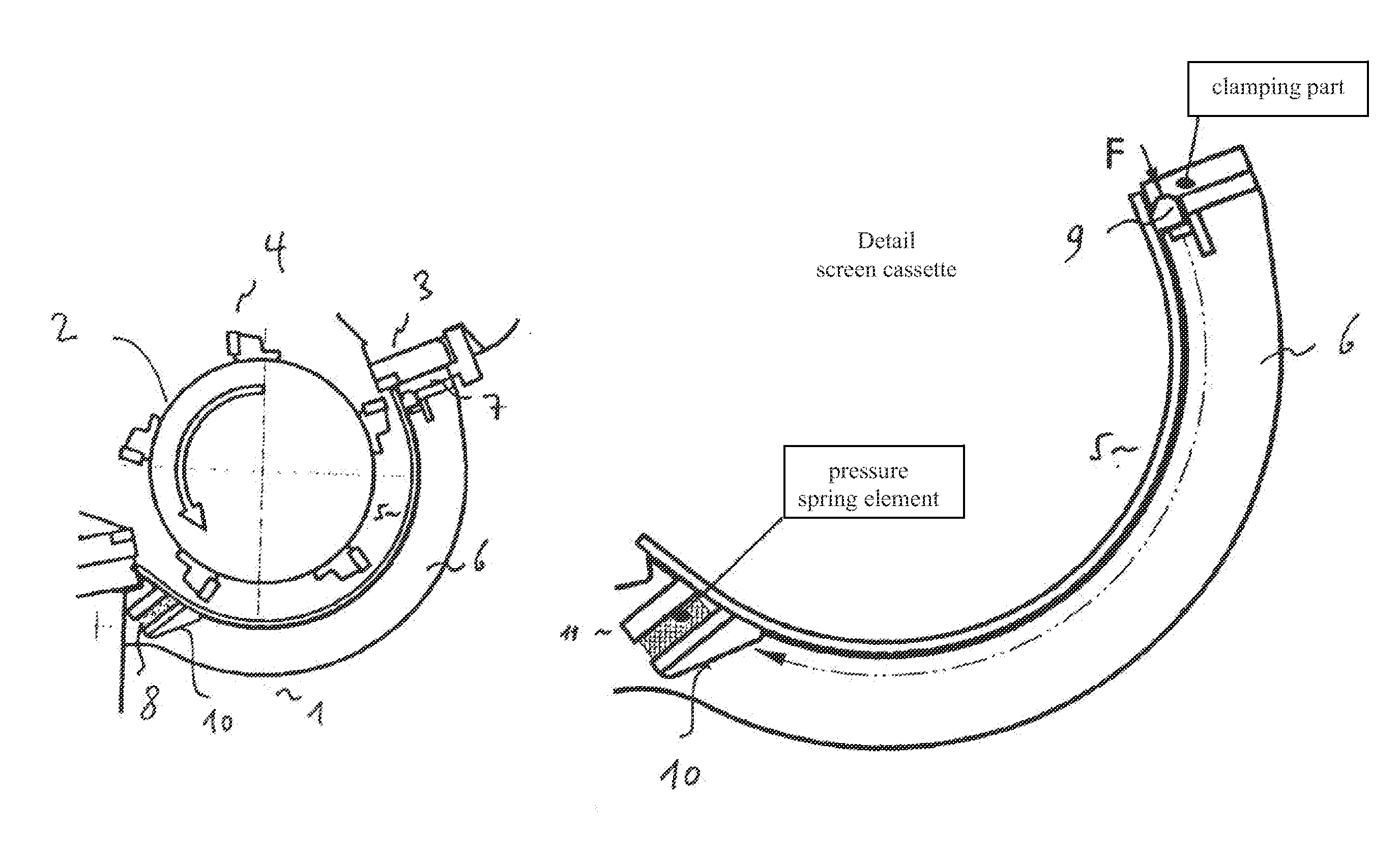

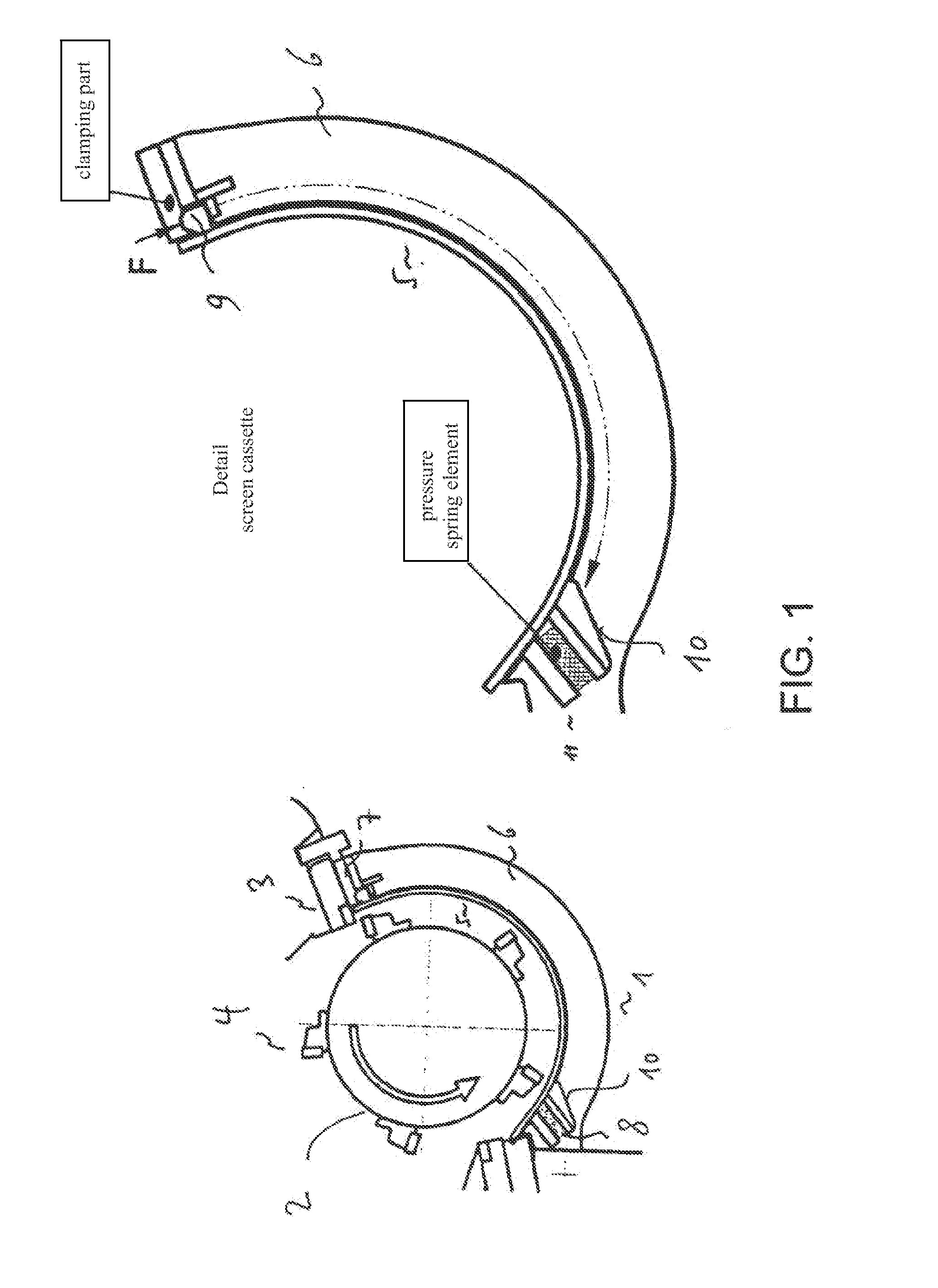

Screen device and fastening means for screen plates

ActiveUS8387904B2Less susceptible to vibrationMore reliableSievingScreeningEngineeringRestoring force

The present invention relates to fastening means for fastening a screen plate onto a screen carrier of a screen device for a comminuting device, comprising a first tensioning element, which is connected to the screen device, particularly to the screen carrier, and which is designed to exert a force on the screen plate; a second tensioning element, which is connected to the screen device, particularly the screen carrier, and which is designed to exert a force on the screen plate, wherein at least one of the tensioning elements is an elastic element, which is designed to exert an elastic restoring force on the screen plate such that the screen plate is tensioned between the first and the second tensioning elements. The invention further relates to a method for fastening a screen plate onto a screen carrier of a screen device for a comminuting device.

Owner:LINDNER MANUEL

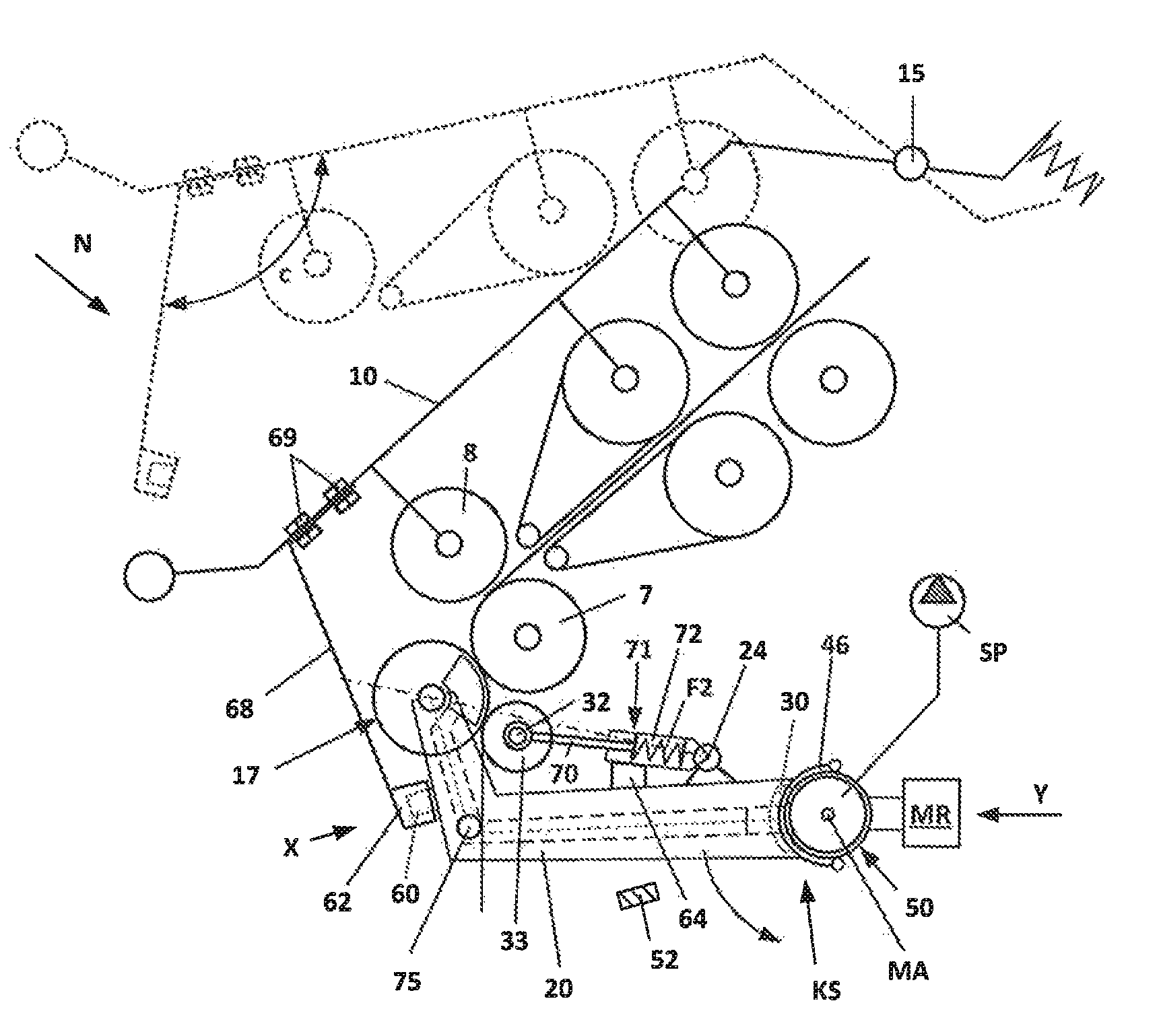

Spinning machine with compactor

ActiveCN103687985BLess susceptible to vibrationAvoid insufficient frictionDrafting machinesContinuous wound-up machinesRotational axisFiber

The invention relates to a device for compacting fiber strands (V) on a spinning machine, comprising a pair of drafting rollers (3, 4; 5, 6; 7, 8) The drafting mechanism unit (2), the pressure rollers (4, 6, 8) of the drafting mechanism roller pair are held on the pressure rod (10) supported on the frame (MR) in a deflectable manner and has a compacting unit (VM) deflectably mounted on the frame (MR) immediately behind the output roller pair (7, 8) of the drafting mechanism unit (2) , the deflection axis (MA) of the compacting unit extends parallel to and spaced relative to the axis of rotation (7a, 8a) of the output roller pair (7, 8), and the compacting unit has a carriage ( 20), at least one suction drum (17) provided with a suction zone (Z) is rotatably supported on said carriage, in order to form a clamping line (P) at the end of said suction zone (Z) , correspondingly a pinch roller (33) fixed on the bracket (20) is placed on the suction drum under the action of the pressure element (F2), and in order to move the output roller pair (7, 8) forming a drive connection between the lower roller (7) and said suction drum (17) via at least one spring element (F1 , 55; 68) load the carriage (20), thereby moving the suction drum (17) towards the lower roller (7) of the output roller pair (7, 8). In order to improve the known solutions, it is proposed to provide guides (30) in the region of the deflection axis (MA) of the carrier (20) of the compaction unit (VM), by means of which the The compaction unit is fixed in the position where it is mounted on the frame (MR), seen in the direction of its deflection axis (MA), and the spring element (F1, 55; 68) is mounted on the compactor on the free end of the rod (10).

Owner:MASCHINENFABRIK RIETER AG

Screen Device and Fastening Means for Screen Plates

ActiveUS20110186665A1Less susceptible to vibrationMore reliableSievingScreeningEngineeringRestoring force

The present invention relates to fastening means for fastening a screen plate onto a screen carrier of a screen device for a comminuting device, comprising a first tensioning element, which is connected to the screen device, particularly to the screen carrier, and which is designed to exert a force on the screen plate; a second tensioning element, which is connected to the screen device, particularly the screen carrier, and which is designed to exert a force on the screen plate, wherein at least one of the tensioning elements is an elastic element, which is designed to exert an elastic restoring force on the screen plate such that the screen plate is tensioned between the first and the second tensioning elements. The invention further relates to a method for fastening a screen plate onto a screen carrier of a screen device for a comminuting device.

Owner:LINDNER MANUEL

MRI device with plasma conductor

ActiveUS20170371014A1Improve image qualityImprove machine performanceMeasurements using NMR imaging systemsCouplingExcited molecule

Owner:ANDERSON THEODORE R

Single slit space carrier shear speckle interferometry system and measurement method

ActiveCN104482875BQuick solveFast dynamic real-time measurementOptically investigating flaws/contaminationUsing optical meansDiffusionTarget surface

The invention discloses a single-slit spatial carrier shearing speckle interferometry measuring system and a measuring method. The measuring system and the measuring method are characterized in that laser shot by a laser device passes through a beam expander and then irradiate a measured object in the form of diffusion light, diffuse reflection light on the surface of the measured object sequentially passes through an imaging lens, a slit diaphragm, a 4f system and a Michelson type device to be projected onto a target surface of an CCD camera. The measuring system and the measuring method can carry out nondestructive, full-field, rapid and dynamic measurement for the defects and stress deformation of the surface of the measured object and is convenient for field measurement.

Owner:HEFEI UNIV OF TECH

Laser focusing adjustment system for realizing interaction with 360-degree configuration of directional beam line

The invention discloses a laser focusing adjustment system for realizing the interaction with the 360-degree configuration of a directional beam line. The laser focusing adjustment system comprises afocusing light path, a focal spot detection alignment system and a vacuum cavity. According to the laser focusing adjustment system for realizing the interaction with the 360-degree configuration of the directional beam line provided by the invention, a laser light is initially and vertically transmitted from top to bottom, an optical axis is s, the directional beam line is transmitted along the horizontal direction, a central axis is t, and the axis s and the axis t intersect at a point O (a fixed laser focal spot position). According to the laser focusing adjustment system for realizing theinteraction with the 360-degree configuration of the directional beam line provided by the invention, a planar mirror (the reflection angle is M, and the M is more than 45 degrees and less than 90 degrees) is used for deflecting the laser light to the side lower part, and then the laser light is reflected by an off-axis paraboloidal mirror (the off-axis angle is N, and the N is equal to 2M-90 degrees) along the horizontal direction and is focused at the point O under the assistance of the focal spot detection alignment system. The planar mirror and the off-axis paraboloidal mirror are stably supported on a three-dimensional pagoda platform. The planar mirror and the off-axis paraboloidal mirror synchronously rotate along the axis s, so that the interaction of the laser light and the 360-degree configuration of the directional beam line at the point O is realized. The laser focusing adjustment system for realizing the interaction with the 360-degree configuration of the directional beamline provided by the invention has the characteristics of simple optical path, low cost, flexible operation and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

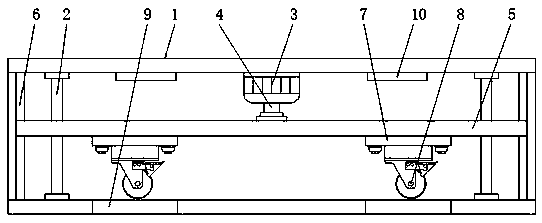

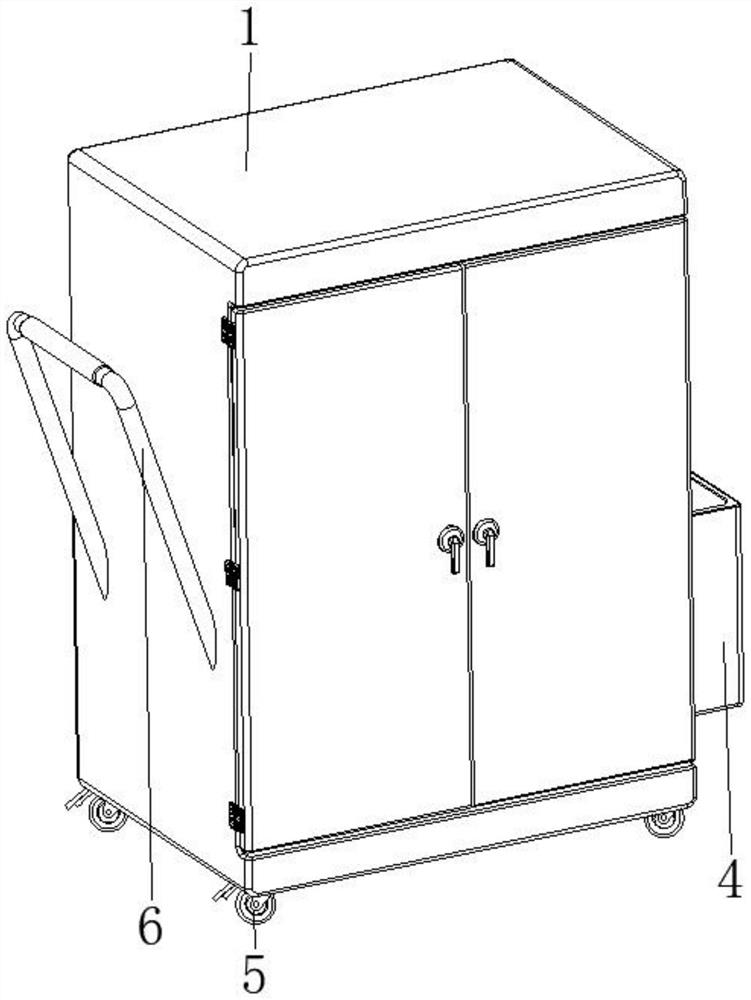

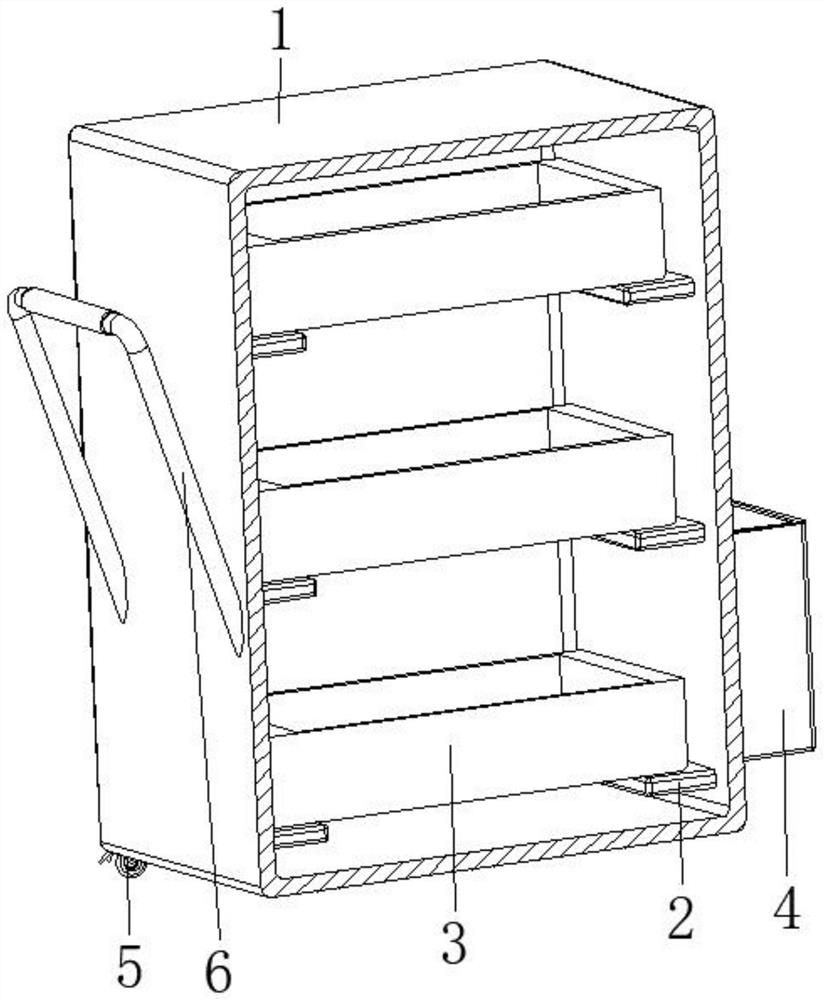

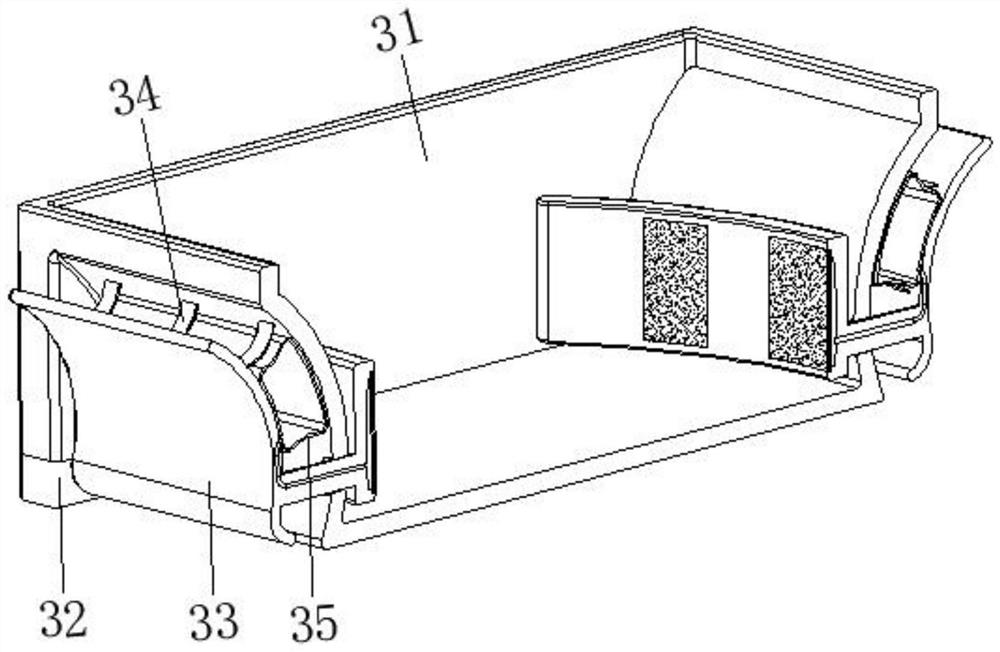

Anti-shaking and anti-toppling nursing trolley for department of pediatrics

PendingCN114748277ALess susceptible to external forcesLess susceptible to vibrationNursing accommodationMedical equipmentNursing care

The anti-shaking and anti-toppling nursing trolley comprises a trolley body, a supporting device and a storage device, the storage device is arranged in the trolley body and close to the supporting device, a magnetic block is arranged at the bottom of a strip-shaped storage box and close to the edge of the end, and a clamping device is arranged at the end of the strip-shaped storage box and close to the magnetic block. The arc-shaped elastic piece is arranged between the two corresponding sides of the surface of the clamping device and the end of the strip-shaped storage box, the elastic bag is arranged at the end of the strip-shaped storage box and close to the clamping device, the air channel is formed in the position, corresponding to the interior of the pressed plate, of the interior of the connecting guide rod, and the clamping plate device is arranged at the end, away from the pressed plate, of the connecting guide rod. The invention relates to the technical field of medical care equipment. According to the anti-shaking and anti-toppling nursing trolley for the pediatric department, the anti-toppling effect is achieved, medicine or medical equipment can be clamped, the trolley is not prone to being affected by external force or vibration, shaking or toppling can be prevented, safety and reliability are achieved, and the use performance is improved.

Owner:JILIN UNIV FIRST HOSPITAL

Turning sheet moving machine for transformer cooling fin production line

InactiveCN114873240ALess susceptible to external forcesLess susceptible to vibrationConveyor partsTransformerEngineering

The invention discloses a transformer cooling fin production line turning sheet moving machine which comprises a rack, a linear driving mechanism, a supporting device and a clamping device, the supporting device is arranged at the bottom output end of the linear driving mechanism, the clamping device is arranged at the bottom of the supporting device, and a pressed device is arranged in a shell and close to a connecting sliding rod. The clamping device is arranged at the end of the connecting sliding rod, the air cylinder is arranged at the position, close to the pressed device, in the shell, the chuck device is arranged on the surface of the clamping base plate, one end of the chuck device is fixedly connected with the end of the curved-surface elastic piece, and the expansion device is arranged in the center of the surface of the clamping base plate. According to the turning piece moving machine for the transformer cooling fin production line, the flexible clamping effect is achieved, cooling fins can be flexibly clamped, the influence of external force or vibration is not likely to happen, clamping is stable, the falling situation is not likely to happen, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:江苏长川科技有限公司

Single-port playing Qiang flute

The invention belongs to the technical field of musical instruments, and relates to a single-port playing Qiang flute which comprises a cavity, a flute pipe, a reed and a mouthpiece; the cavity is arranged on the flute pipe, the reed is arranged on the flute pipe, and the reed is accommodated in the cavity; the mouthpiece is arranged on the cavity, and the mouthpiece is communicated with the flutepipe through the cavity. According to the single-port playing Qiang flute, the cavity is arranged on the flute pipe; the reed and part of the flute pipe are accommodated in the cavity, and the mouthpiece for playing is arranged on the cavity, so that the oral cavity is not in direct contact with the reed and the flute pipe, saliva can be prevented from being adhered to the reed while normal playing is not influenced, the vibration of the reed is not easily influenced, and the occurrence probability of a sound breaking phenomenon of the reed is reduced; in addition, the oral cavity only wrapsthe mouthpiece during playing, so that the burden of the oral cavity can be reduced, and playing is facilitated.

Owner:袁永杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com