Spinning machine with compactor

A spinning machine, compaction unit technology, applied in the spinning machine, continuous winding spinning machine, textile and papermaking, etc., can solve the problem of not being aligned with each other accurately, and achieve the effect of fast operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

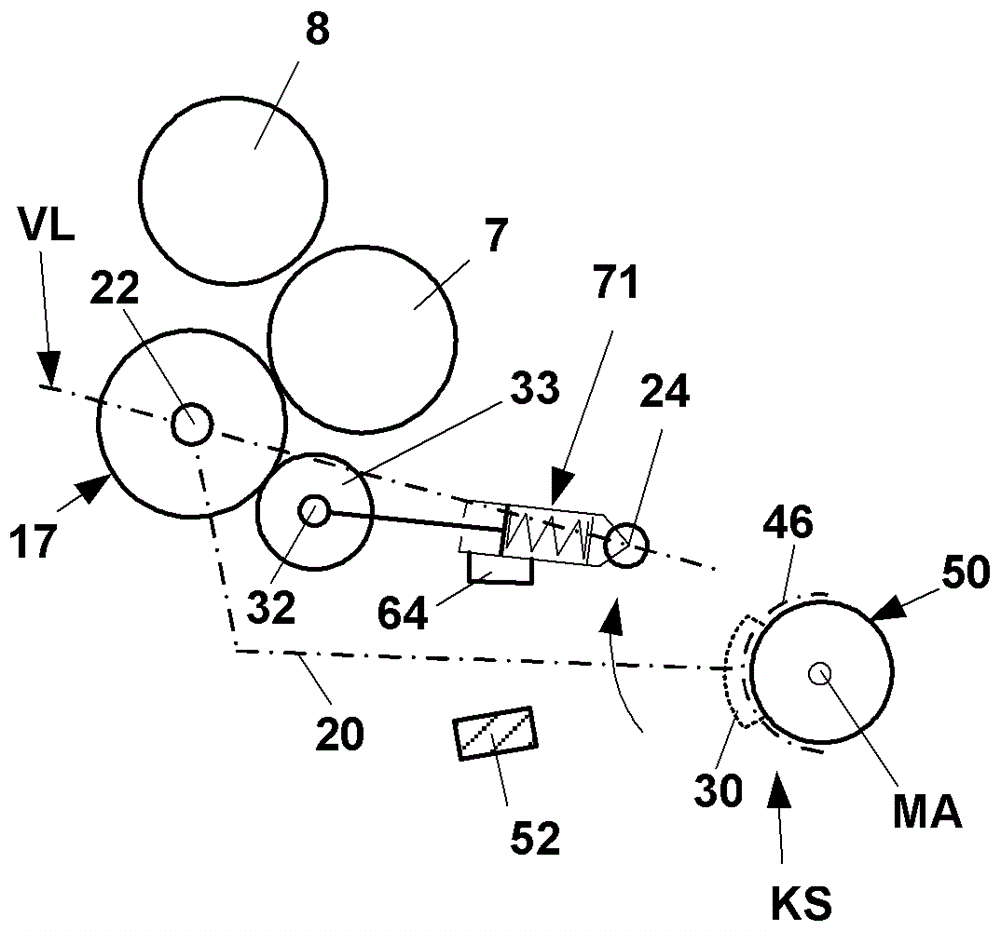

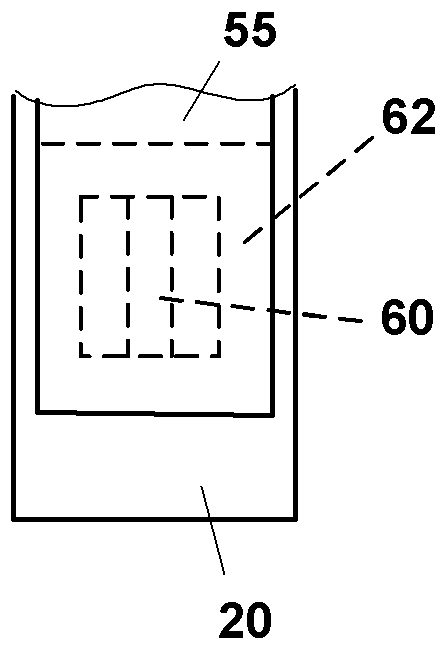

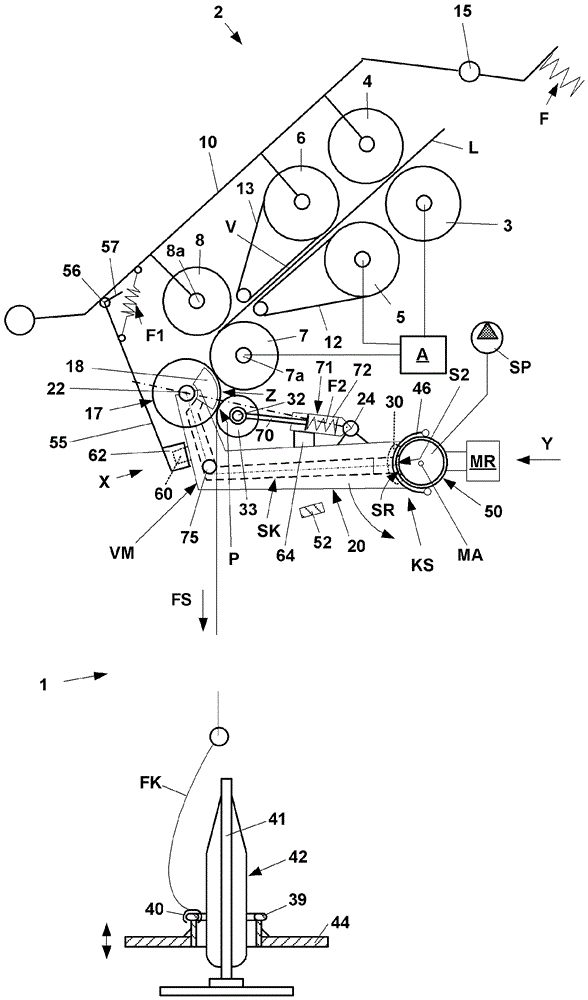

[0035] figure 1 Shows a schematic side view of a spinning position 1 of a spinning machine (ring spinning frame) with drafting unit 2 provided with input roller pairs 3, 4, intermediate rollers Pair 5, 6 and output roller pair 7, 8. A belt 12 , 13 is each guided around the intermediate roller pair 5 , 6 , and is held in its position shown in each case around a cage (not shown in detail). The upper rollers 4 , 6 , 8 of the roller pairs mentioned are designed as pressure rollers, which are mounted rotatably via shafts on pivotally mounted pressure rods 10 . The pressure rod 10 is mounted so as to be pivotable about an axis 15 , which is acted upon by a spring element F as schematically shown. This spring element can also be an air hose, for example. By means of the schematically indicated spring loading, the rollers 4, 6, 8 are pressed against the lower rollers 3, 5 and 7 of the roller pair in order to form a clamp for the spinning material bit. The roller pairs 3 , 5 , 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com