Structure for mounting boring cutter in embedding manner

An installation structure and embedded technology, which is applied in the accessories of tool holders, tools for lathes, turning equipment, etc., can solve the problem of unreasonable design of boring tool installation structure, poor installation stability of workpieces to be processed, and affecting the machining accuracy of parts, etc. problem, to achieve the effect of novel structural design, improved stability and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

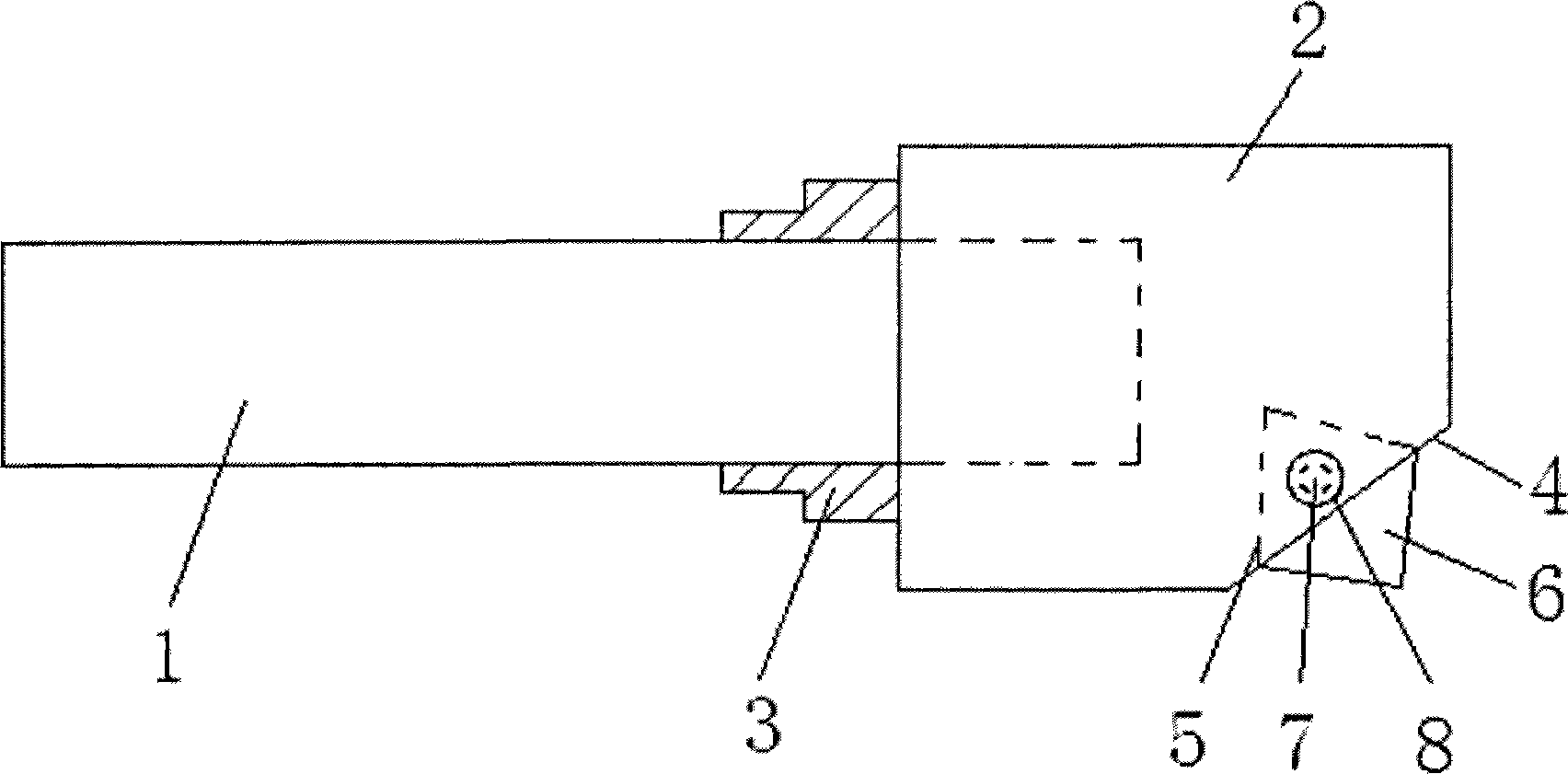

[0011] see figure 1 :

[0012] The installation structure of the embedded boring tool includes the tool bar 1, the front end of the tool bar 1 is screwed to install a block-shaped tool seat 2, the outer wall of the tool bar 1 is screwed to install a locking sleeve 3, and the front surface of the locking sleeve 3 withstands the tool seat 2. Use the locking sleeve to ensure that the connection between the knife rod and the knife seat 2 is firm, and it is not easily affected by vibration. The lower right corner of the knife seat 2 is inclined at 30° to 60° and cut into a bevel 4. There is a knife extending into the bevel 4 The triangular mounting hole 5 in the seat 2 is embedded with a boring tool 6, which improves the stability and firmness of the boring tool 6 during use after it is installed. The front end of the tool seat 2 has a The locking hole 7 facing the mounting hole 5 is screwed with a locking bolt 8 in the locking hole 7, and the front end of the locking bolt 8 withs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com