Concentration and crystallization device for N-methylformamide

A methylformamide and concentrated crystallization technology, which is applied in the field of N-methylformamide concentrated crystallization devices, can solve the problem of inability to perform buffering and shock absorption, shock isolation, lower performance, and unfavorable N-methylformamide concentration and crystallization. and other problems to achieve the effect of improving work efficiency and performance, improving performance, and reducing random movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

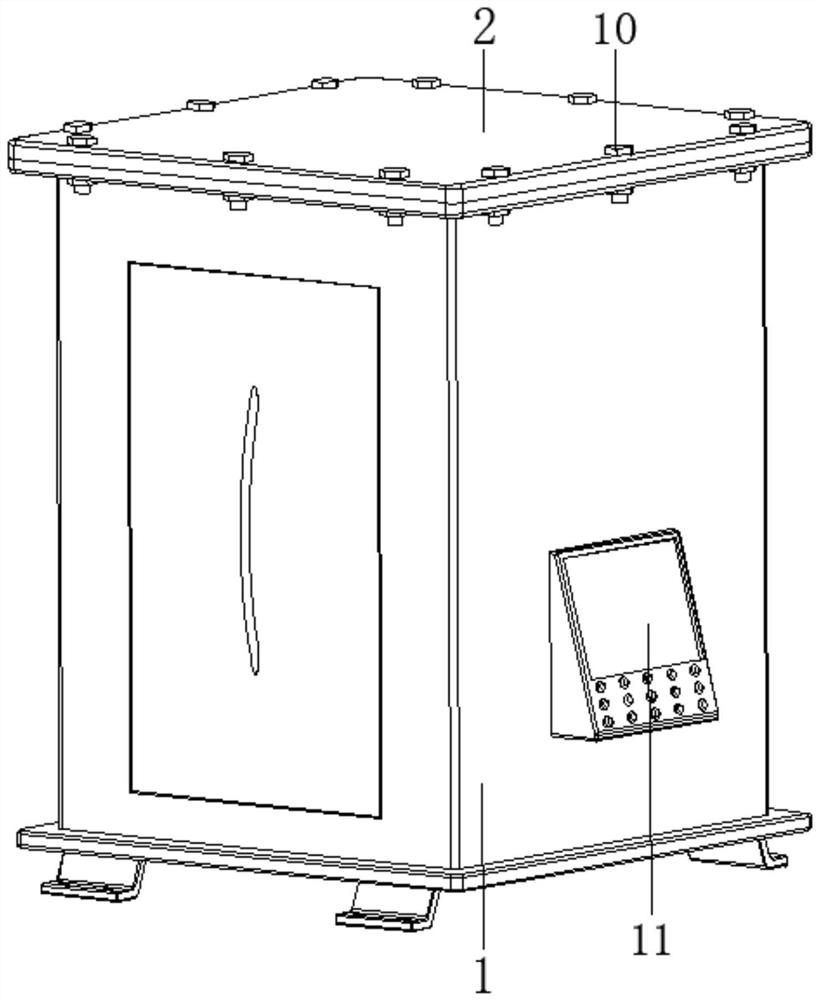

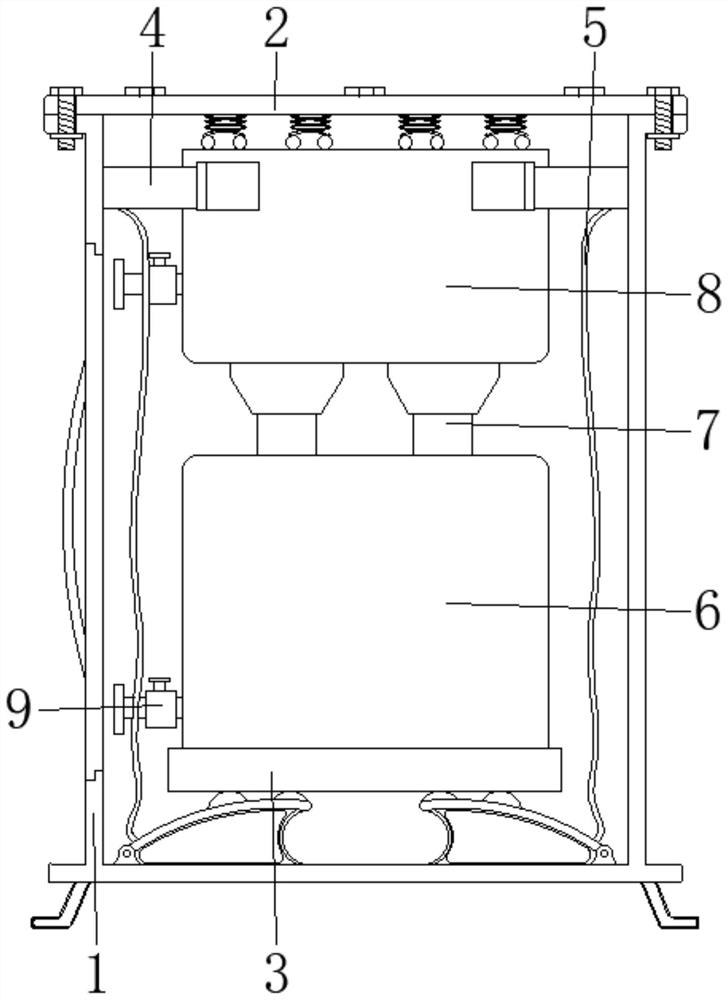

[0032] see Figure 1-Figure 7 , the present invention provides a technical solution: a concentrated crystallization device for N-methylformamide, including a body 1, an elastic pressing device 2, a buffer device 3, a limiting device 4, a connecting hose 5, and the elastic pressing device 2 is set On the top of the body 1, the buffer device 3 is arranged at the bottom of the inner wall of the body 1, the limit device 4 is arranged on the inner wall of the body 1 and is close to the top position, and the connecting hose 5 is arranged on the two sides corresponding to the buffer device 3 and the limit device 4. between the sides;

[0033] A crystallization mechanism 6 is provided inside the body 1 and at the position of the placement tank 32. A conduit 7 is provided on the top of the crystallization mechanism 6. A distillation mechanism 8 is provided on the top of the conduit 7 and at the position of the limiting device 4. The surface of the crystallization mechanism 6 One side ...

Embodiment 2

[0036] Elastic pressing device 2 is provided with cover plate 21, stage clip 22, connecting plate 23, flexible bar 24, and cover plate 21 is arranged on the top of body 1, and the top of stage clip 22 is fixed on the bottom of cover plate 21, and the top of connecting plate 23 Fixed on the bottom of the compression spring 22, the top of the surface of the flexible rod 24 is fixedly connected with the bottom of the connecting plate 23.

[0037] Compression spring 22 is evenly distributed on the bottom of cover plate 21, and the material of flexible rod 24 is set to rubber material, and the top of cover plate 21 and body 1 is fixed by locking bolt 10, and then makes compression spring 22, connecting plate 23, flexible The rod 24 is pressed, and the pressing force is applied to the distillation mechanism 8 through the flexible rod 24, and the material of the flexible rod 24 is made of rubber, so that it is in flexible contact. At the same time, the reverse elastic resistance, and...

Embodiment 3

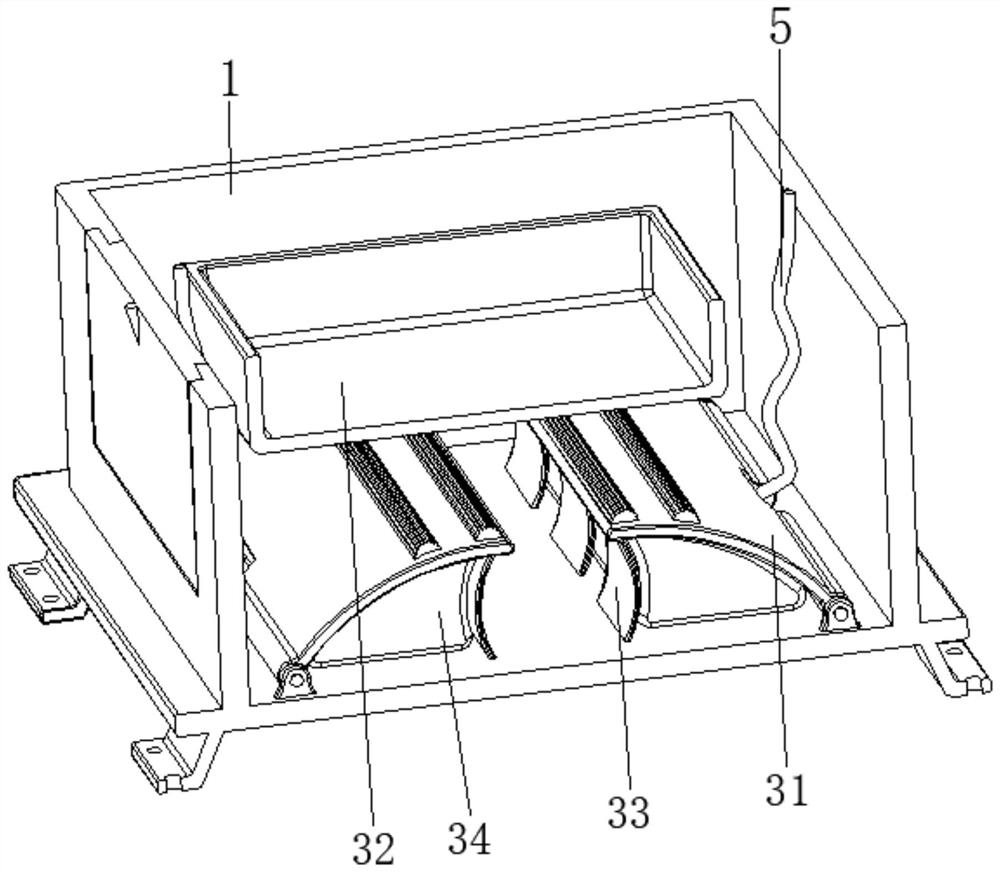

[0039] The buffer device 3 is provided with a holding device 31, a placement groove 32, an arc-shaped elastic member 33, and an inflatable air bag 34. The holding device 31 is arranged at the bottom of the inner wall of the body 1, and the placement groove 32 is arranged inside the body 1 and is located in the holding device. 31, the arc-shaped elastic member 33 is fixed between the end of the holding device 31 and the two sides corresponding to the bottom of the inner wall of the body 1, and the inflatable airbag 34 is arranged on the two sides corresponding to the bottom of the holding device 31 and the bottom of the inner wall of the body 1 Between and close to the arc-shaped elastic member 33 , the air port of the inflatable airbag 34 communicates with the bottom end of the connecting hose 5 .

[0040] The holding device 31 is provided with an arc-shaped base plate 311, a support bar 312, and an anti-skid layer 313. One side of the surface edge of the arc-shaped base plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com