Isolation grounding switch and operating mechanism thereof

A technology for isolating grounding switches and operating mechanisms, applied in grounding switches, contact operating mechanisms, electrical switches, etc., to achieve the effects of convenient operation, improved user experience, and reduced economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

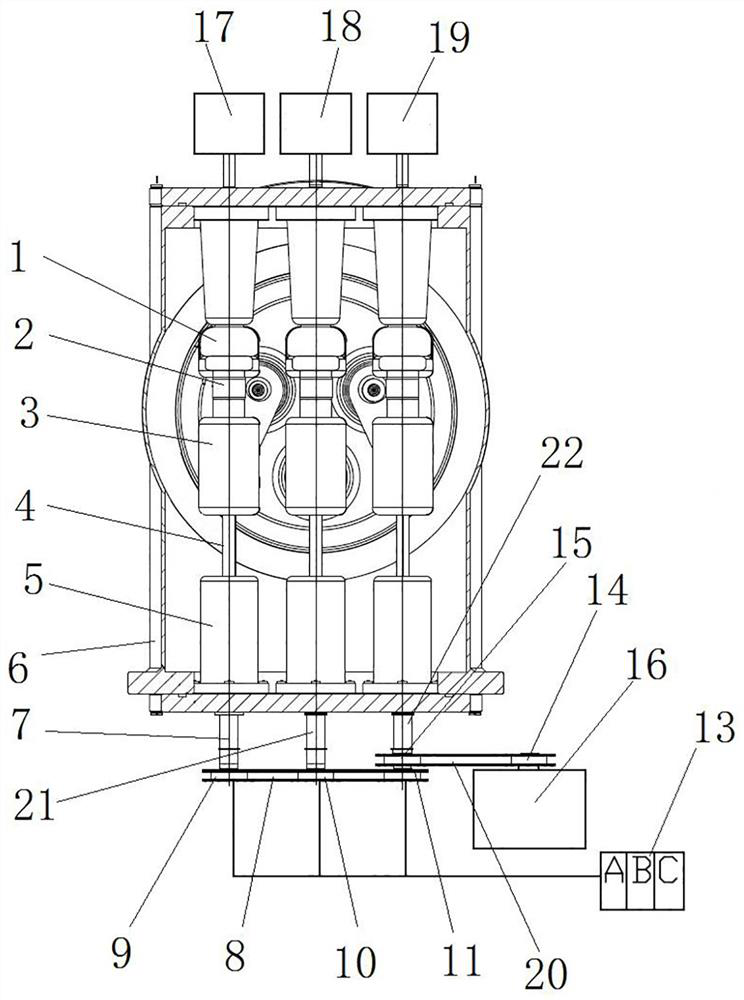

[0049] Such as figure 1 As shown, the isolation grounding switch includes a cylinder body 6, and the cylinder body 6 is provided with three sets of gate contact seats 1, three sets of moving contacts 2, three sets of intermediate contact seats 3, three sets of screw rods 4 and three sets of ground contact seats 5; The closing contact seat 1, the intermediate contact seat 3 and the grounding contact seat 5 are arranged at intervals in the axial direction of the cylinder body 6, and the movable contact 2 is electrically conductive and slidably assembled in the intermediate contact seat 3 along the axial direction of the cylinder body 6. The corresponding screw rod 4 is threaded, and the moving contact 2 is driven to slide through the rotation of the screw rod 4, so that the moving contact 2 is in contact with the closing contact seat 1, the moving contact 2 is separated from the closing contact seat 1, and the moving contact 2 is in contact with the closing contact seat 1. The g...

Embodiment 2

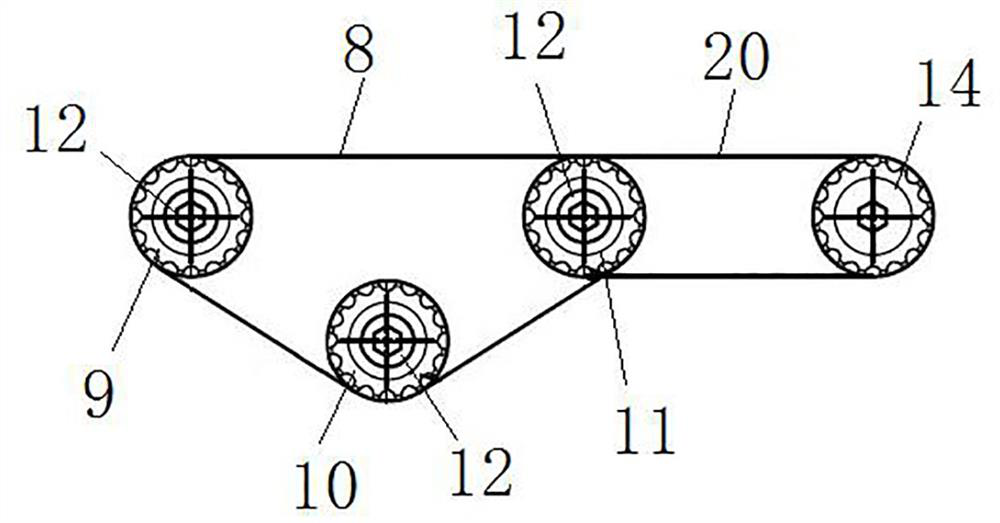

[0061] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the three clutches 12 are all electromagnetic clutches, and the controller 13 remotely controls the clutch 12 to work; while in this embodiment, the three clutches are all mechanical clutches , the mechanical clutch works through manual control.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the A-phase driving wheel is the A-phase sprocket 9, the B-phase driving wheel is the B-phase sprocket 10, and the C-phase driving wheel is the C-phase sprocket 11. , A-phase sprocket 9, B-phase sprocket 10 and C-phase sprocket 11 are connected through the interphase chain 8 to realize synchronous rotation; and in this embodiment, the A-phase drive wheel is an A-phase gear, and the B-phase drive The wheel is a B-phase gear, the C-phase driving wheel is a C-phase gear, and the A-phase gear, B-phase gear, and C-phase gear are connected through an intermediate gear to realize synchronous rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com