Lithium battery work control method and system, and electric equipment

A work control, electric equipment technology, applied in battery circuit devices, electric vehicles, current collectors, etc., can solve problems such as danger and power failure, and achieve the effect of avoiding vehicle loss of control or braking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

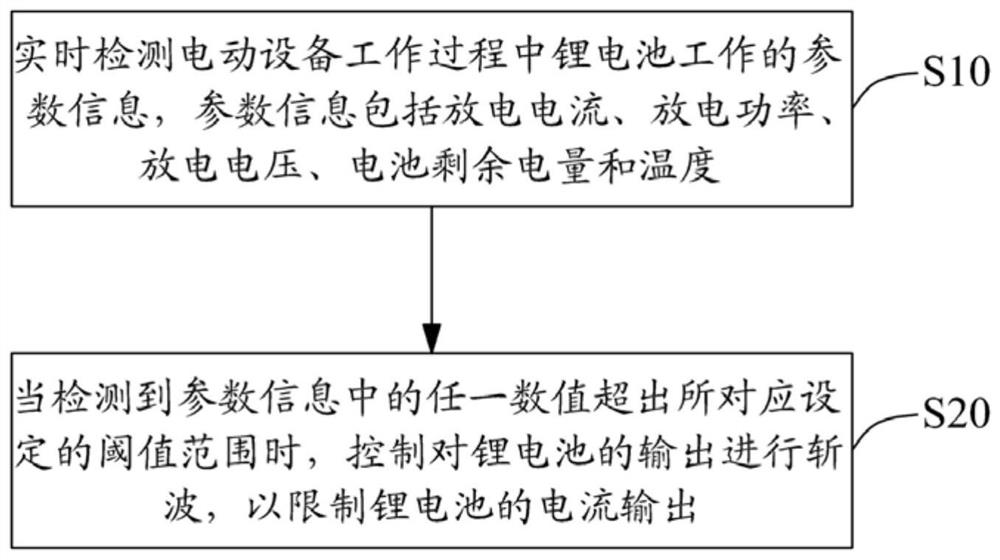

[0045] see figure 1 , is a schematic flowchart of the lithium battery operation control method provided in the first embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The lithium battery operation control method is applied to electric equipment, and the method includes:

[0046] Step S10, real-time detection of the parameter information of the lithium battery during the operation of the electric device, the parameter information includes discharge current, discharge power, discharge voltage, remaining battery power and temperature;

[0047] Wherein, in the embodiment of the present invention, the lithium battery operation control method is applied to electric equipment such as electric vehicles, wherein the electric equipment in this embodiment uses a lithium battery pack composed of a plurality of lithium battery units as a power source, Among them, the electric equipment is also...

Embodiment 2

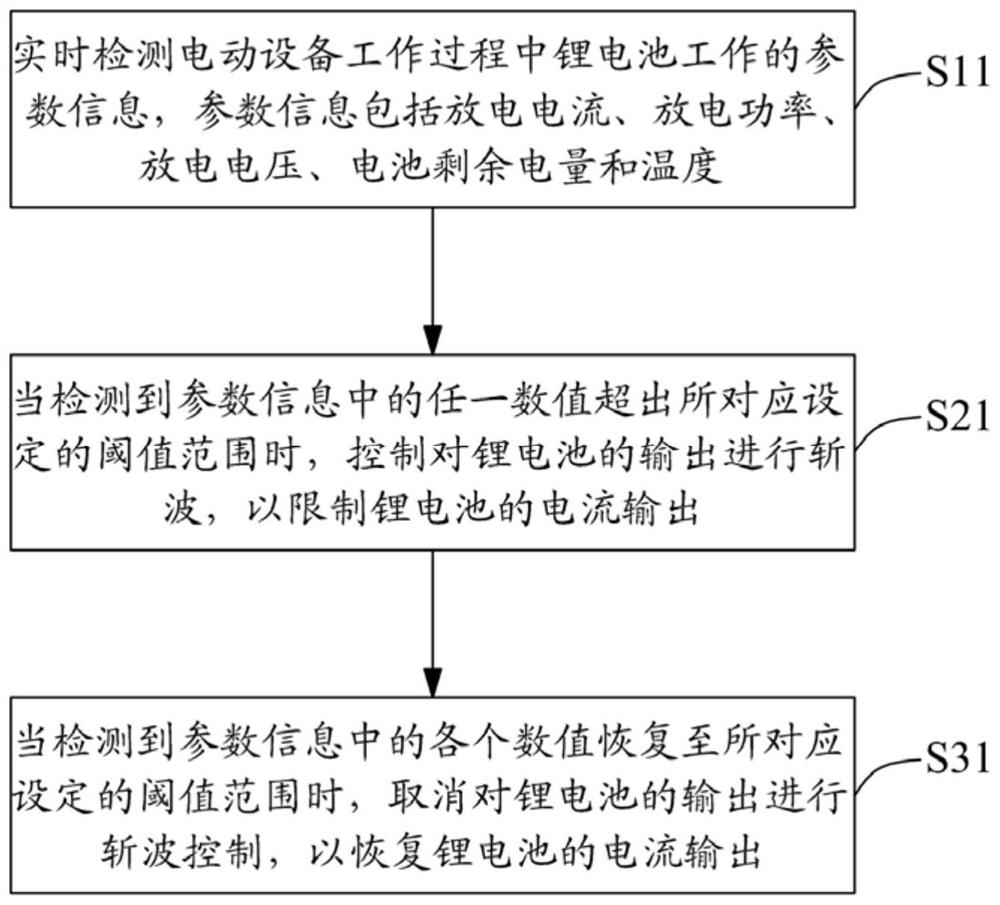

[0057] see figure 2 , is a schematic flowchart of a lithium battery operation control method provided by the second embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The lithium battery operation control method is applied to electric equipment. The method include:

[0058] Step S11, real-time detection of the parameter information of the lithium battery during the operation of the electric device, the parameter information includes discharge current, discharge power, discharge voltage, remaining battery power and temperature.

[0059] Step S21, when it is detected that any value in the parameter information exceeds the corresponding set threshold range, control the chopping of the output of the lithium battery to limit the current output of the lithium battery;

[0060] Among them, in the embodiment of the present invention, when the BMS system detects that any one of the disc...

Embodiment 3

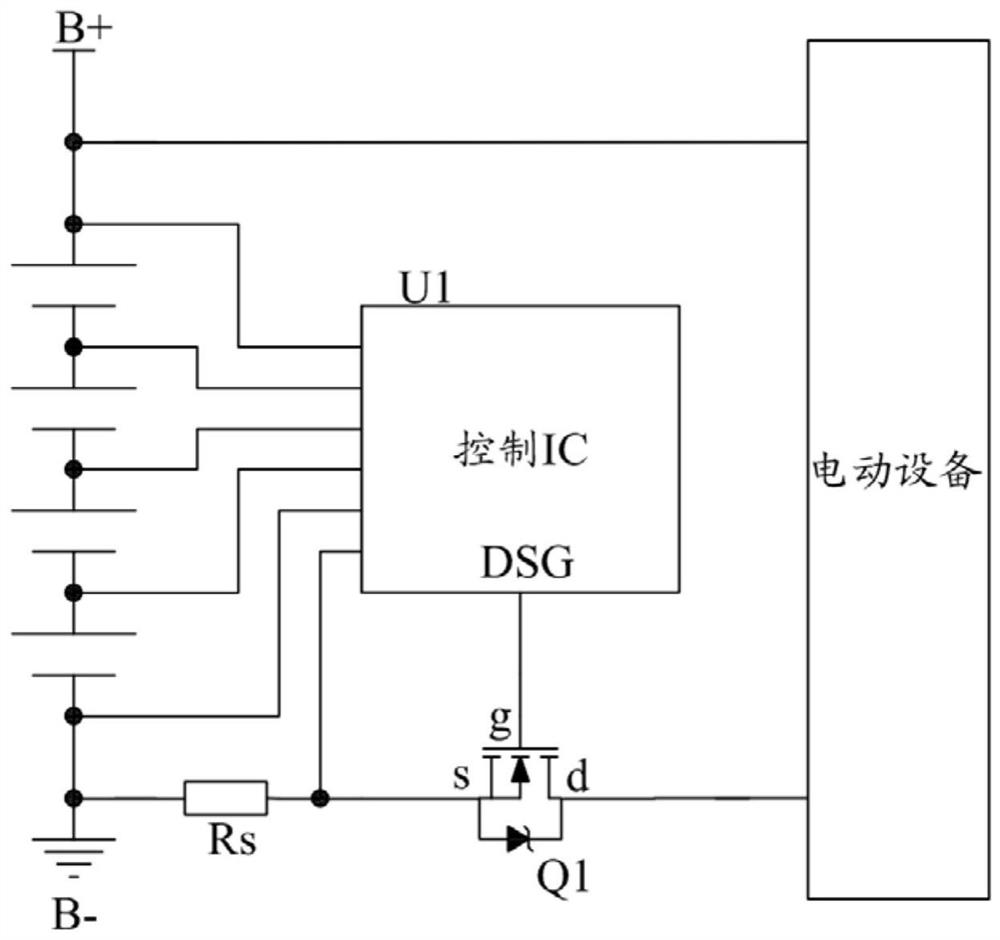

[0078] see Figure 4 , is a schematic structural diagram of the lithium battery operation control system provided by the third embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The lithium battery operation control system is applied to electric equipment, and the system includes :

[0079] The parameter information detection module 10 is used to detect in real time the parameter information of the lithium battery during the operation of the electric device, and the parameter information includes discharge current, discharge power, discharge voltage, remaining battery power and temperature;

[0080] The chopping control module 20 is used to control the output of the lithium battery to chop when the parameter information detection module 10 detects that any value in the parameter information exceeds the corresponding set threshold range, so as to limit the output of the lithium ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com