A circuit board anti-oxidation treatment equipment

A processing equipment and anti-oxidation technology, applied in secondary processing of printed circuits, circuit processing tools/objects, and positioning of circuit board tools, etc., can solve problems such as low circuit board processing efficiency, and achieve the effect of convenient operation and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

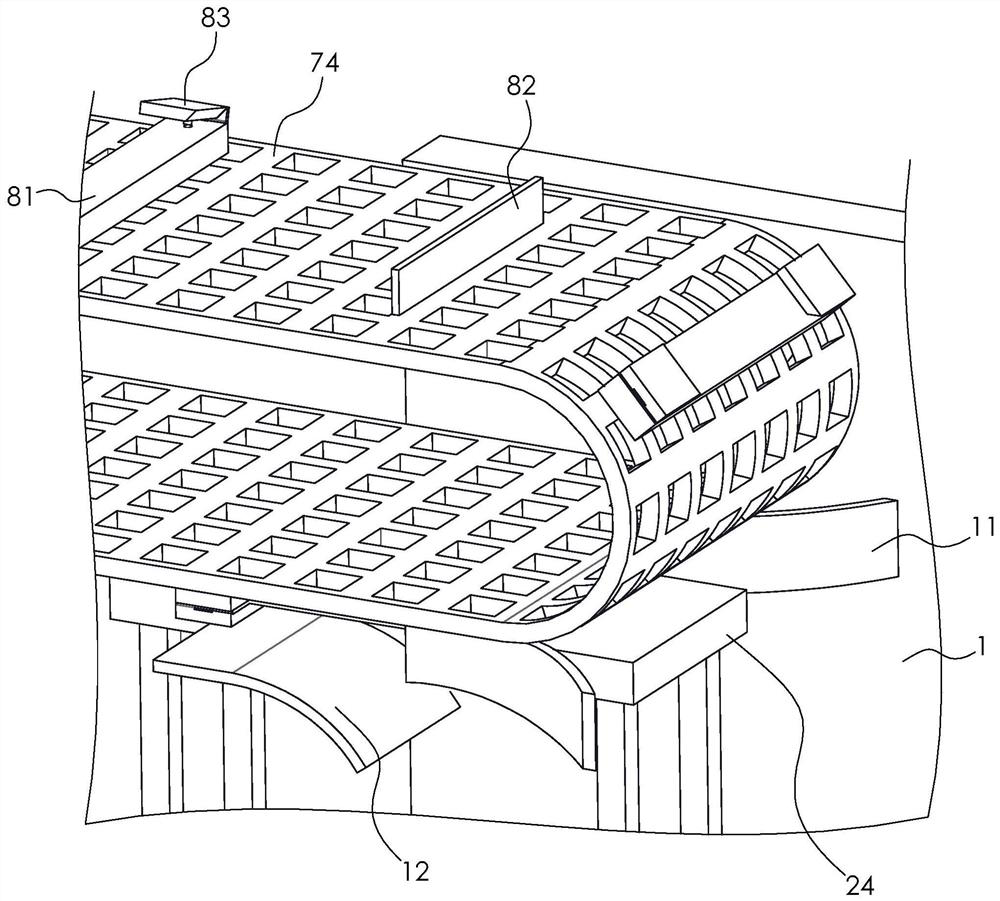

[0035] The following is attached Figure 1-8 The application is described in further detail.

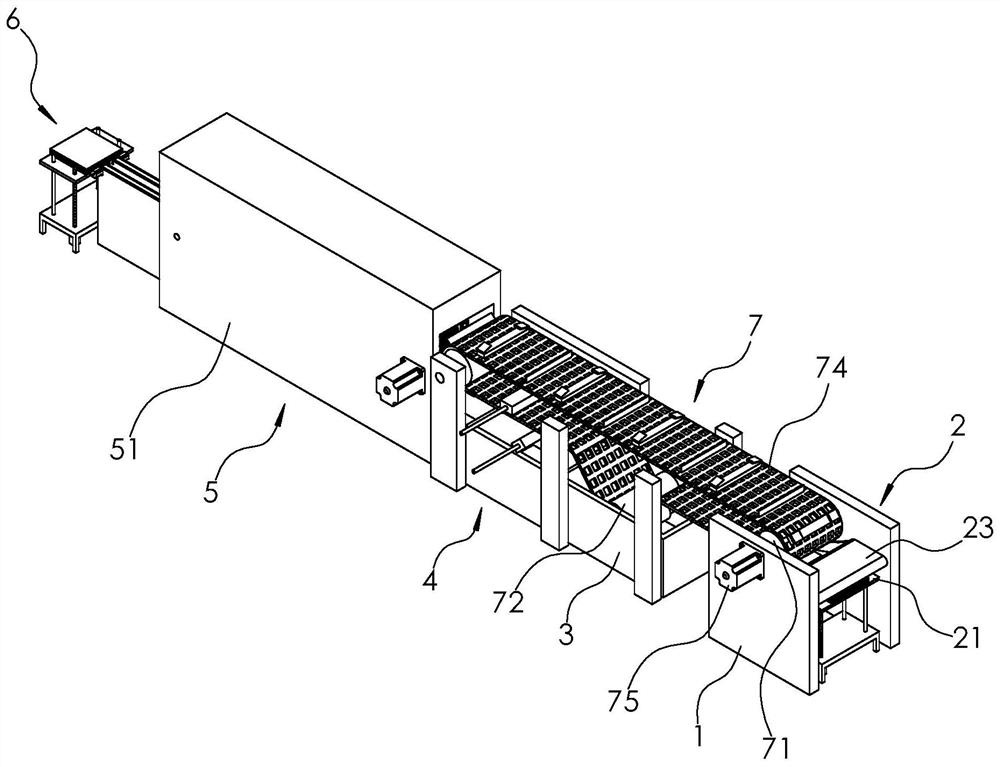

[0036] The embodiment of the present application discloses a circuit board anti-oxidation treatment equipment. Such as figure 1 As shown, a circuit board anti-oxidation treatment equipment includes a bracket 1, a feeding mechanism 2 arranged in sequence, an anti-oxidation pool 3, a water spray mechanism 4, a drying mechanism 5 and a feeding mechanism 6, and the bracket 1 is provided with a The conveying mechanism 7 above the anti-oxidation pool 3.

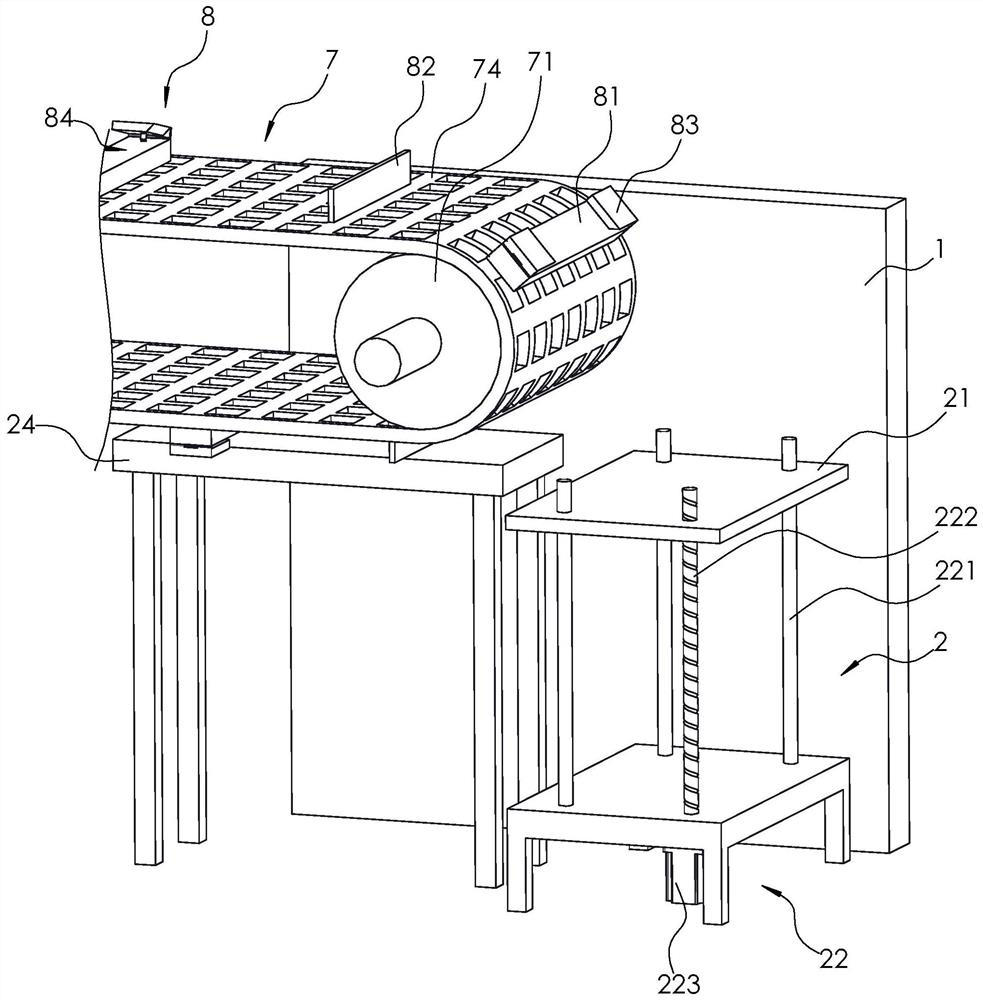

[0037] Such as figure 1 and figure 2 As shown, the feeding mechanism 2 includes a material preparation platform 21, a second lifting assembly 22, a third conveyor belt 23 and a placement platform 24 located at the input end of the conveying mechanism 7, and the second lifting assembly 22 includes three vertically extending through-holes. Set the rod 221, a screw mandrel 222 extending in the vertical direction and the second motor 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com