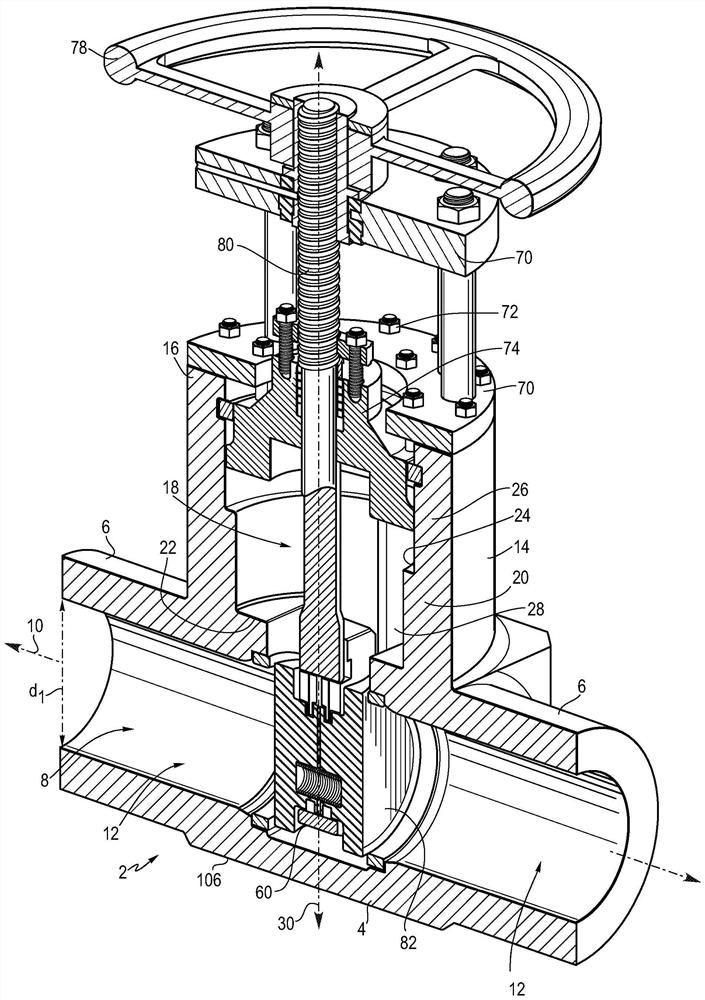

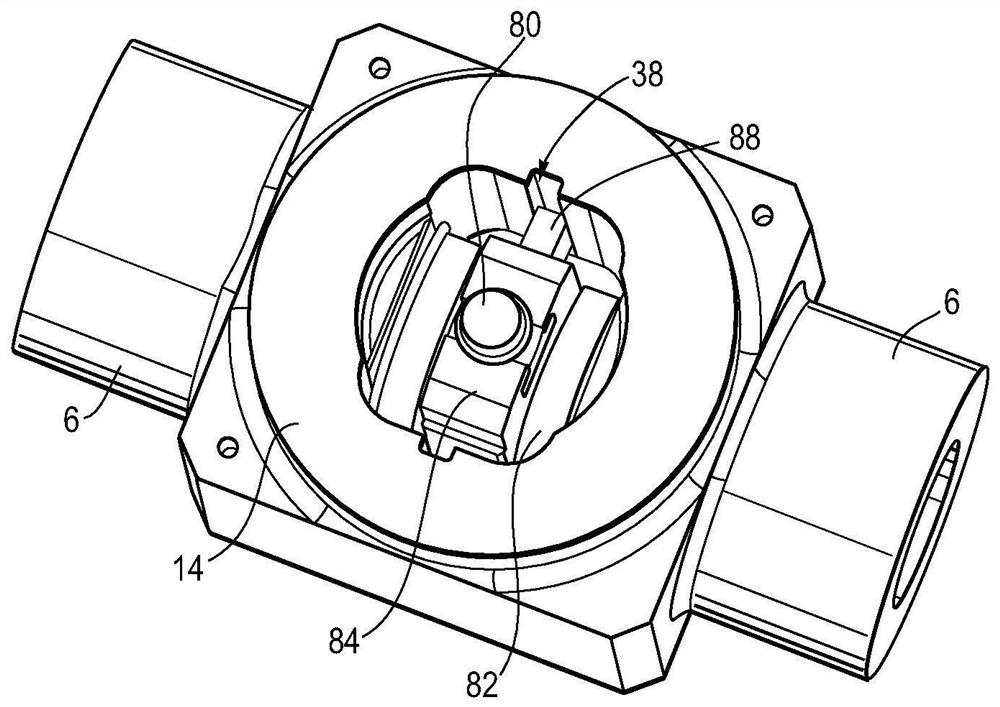

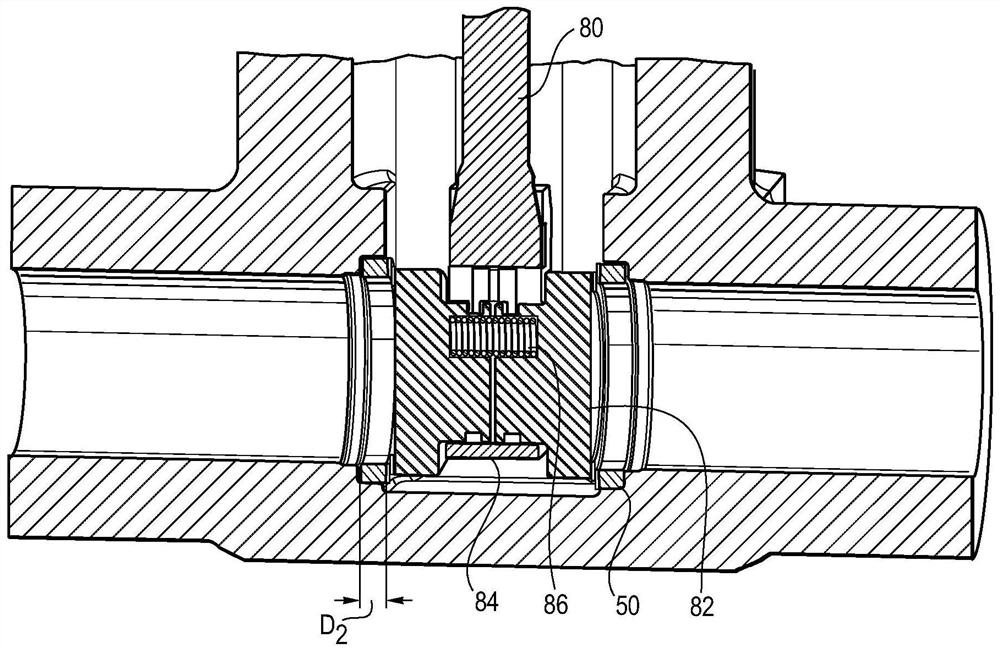

Method for manufacturing block forged valve body with fully encapsulated seat ring

A technology of integral forging, valve body, applied in the direction of valve device, valve detail, sliding valve, etc., can solve the problem of extra, easy to leak, etc., to achieve the effect of avoiding the need and ensuring the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the term "plurality" as used herein means two or more. The terms "outer side" and "inner side" refer to the relative positions of various features with respect to a common axis or plane. The term "coupled" means directly or indirectly connected to or engaged with, eg, an intermediate member, and does not require the engagement to be fixed or permanent, although the engagement may be (or integral). The terms "first", "second", etc. as used herein do not imply an assignment to a particular component so designated, but merely refer to these components in the numerical order mentioned, which means that the specified An element being "first" may be followed by such an element being "second," depending on the order in which the elements are mentioned. For example, depending on the order in which the "first" diameter and the "second" diameter are referred to, the "first" diameter may hereinafter be referred to as the "second" diameter. It should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com