Polyester resin having improved adhesion strength for binder and polyester fiber using same

A technology of polyester resin and polyester fiber, which is applied in the field of polyester resin for adhesives, can solve the problems of reducing the uniformity of the physical properties of polyester fibers, high fluidity, and reduced melt viscosity, etc., so as to improve the spinning process. The effect of uniformity, uniformity of physical properties, and improved adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6

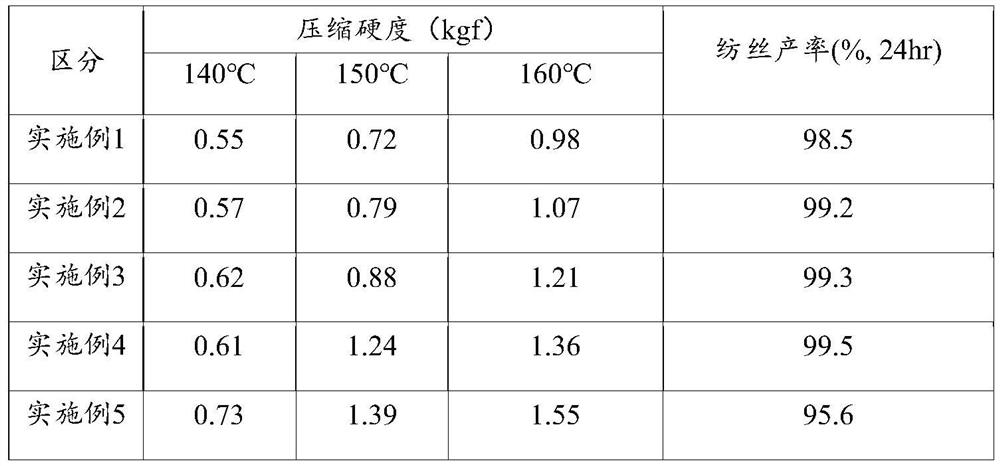

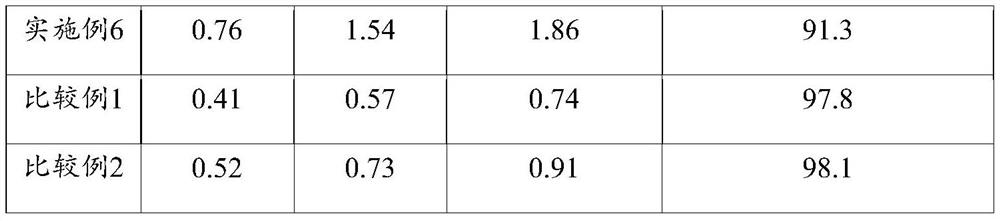

[0058] The core layer uses polyethylene terephthalate with a melt viscosity of about 2300 poise at 280°C, and the skin layer uses polyester resin for adhesives. The weight ratio of the skin layer to the core layer is 50:50 through conventional The composite spinning process of the present invention produced the polyester fiber for binders with improved processability.

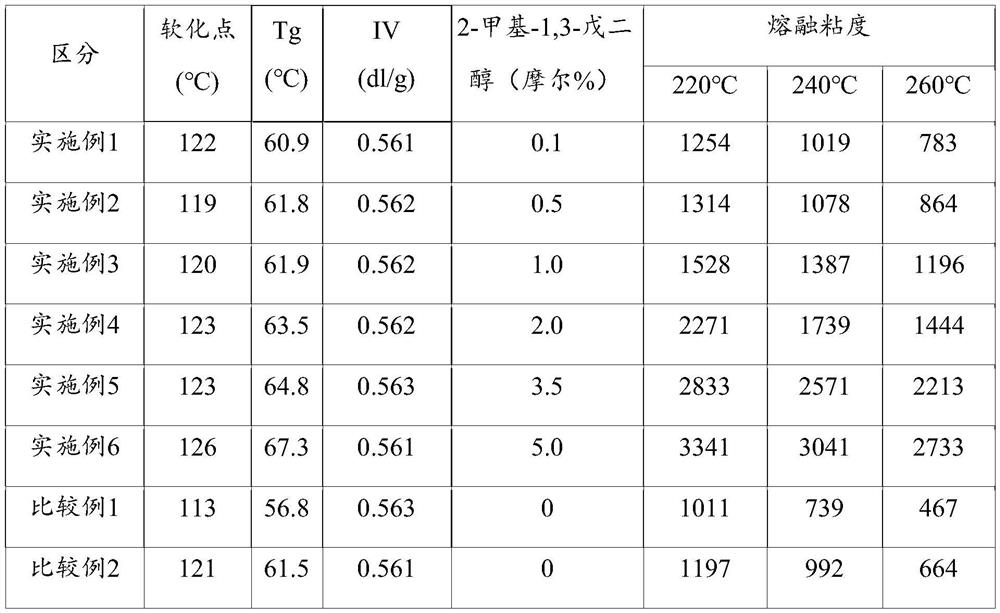

[0059] The polyester resin for the adhesive is prepared through the following steps: adding terephthalic acid (TPA) and ethylene glycol (EG) to an ester reaction kettle, and performing conventional polymerization at 258°C to prepare a poly Ethylene phthalate polymer (PET oligomer), the reaction rate is about 96%. The obtained polyethylene terephthalate (PET) contains 2-methyl-1,3-propanediol accounting for about 42 mol% of diol components, and 2-methyl-1,3- Pentanediol was mixed at the content ratio shown in Table 1 below, and then a transesterification catalyst was added, and transesterification was performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt viscosity | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com