Decontamination paste and method for decontaminating a substrate made of a solid material using said paste

A paste and substrate technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of unstable solid materials, no decontamination composition, etc., and achieve the effect of high decontamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0279] In this example, the preparation of two surface, subsurface and deep, deep stain removal pastes referred to as "Paste-1" and "Paste-2" according to the present invention is described.

[0280] Paste-1 is a paste with the following composition:

[0281] -0.8% by weight (based on the total weight of the paste) of Selling Cellulose BC 1000 (fiber size about 700μm);

[0282] -49.6% by weight (based on the total weight of the paste) of sales of kaolinite; and

[0283] - 49.6% by weight (based on the total weight of the paste) of deionized water.

[0284] Paste-2 is a paste with the following composition:

[0285] -8% by weight (based on the total weight of the paste) of Selling Cellulose BC 1000 (fiber size about 700μm);

[0286] -20% by weight (based on the total weight of the paste) of sales of kaolinite; and

[0287] - 72% by weight (based on the total weight of the paste) of deionized water.

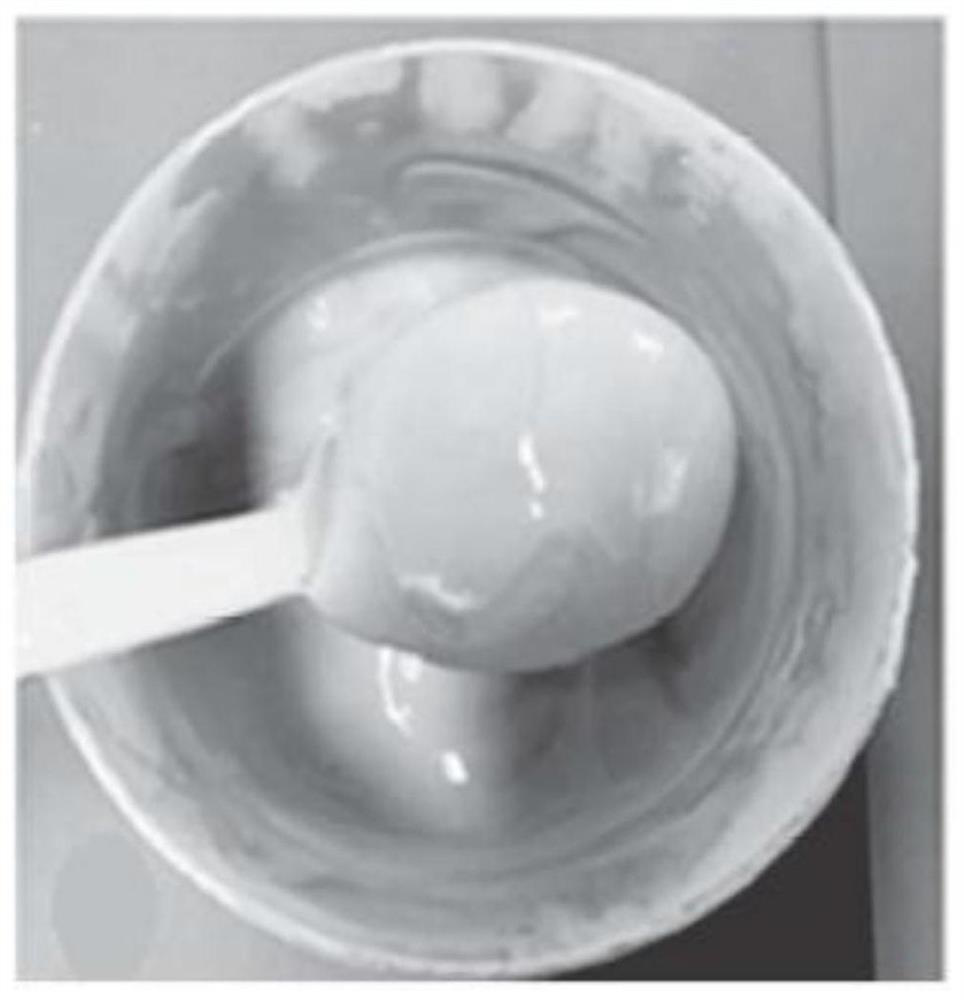

[0288] The synthetic schemes for the two pastes are similar:

[...

Embodiment 2

[0296] In this example, the efficiency of the paste according to the invention, namely Paste-1 prepared in Example 1, for surface, subsurface and deep, deep decontamination of porous materials is demonstrated.

[0297] More precisely, in this example, the decontamination of a porous material consisting of a stack of glass beads coated with 133 Cs deep pollution.

[0298] The soil release paste according to the invention used in this example was Paste-1 prepared in Example 1.

[0299]The porous material used was a stack of glass beads with a size between 45 μm and 90 μm prepared in a circular crystallization dish with a diameter of 9.1 cm.

[0300] The 2 cm high glass beads thus prepared were heaped with 43.42 mL of CsNO 3 CsNO at a concentration of 0.016M 3 Soak and saturate with aqueous solution. In the glass bead heap there is 93mg of 133 Cs.

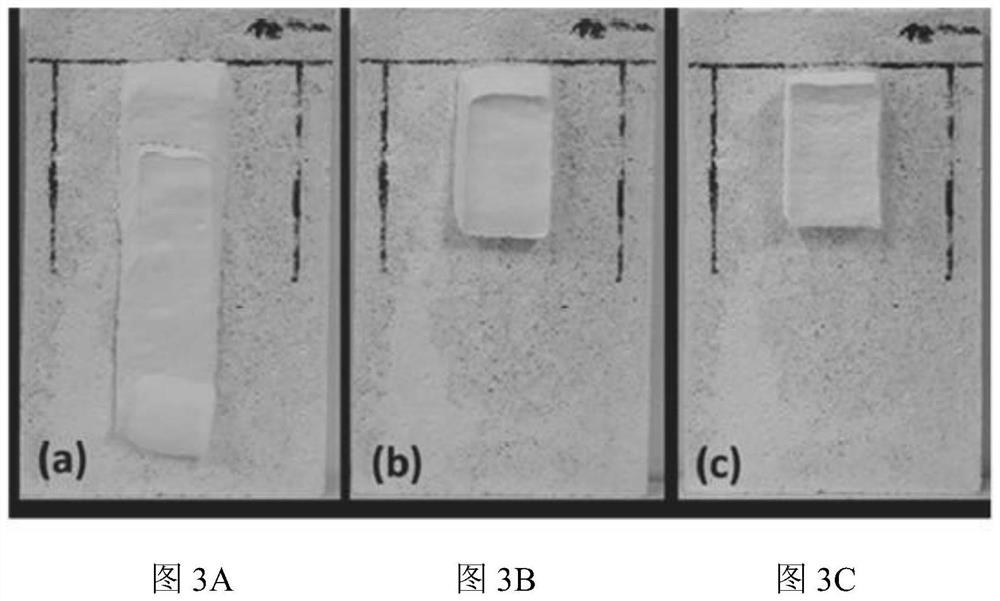

[0301] A 2 cm paste-1 layer was then placed on top of the heap of glass beads saturated with solution. The whole is then allo...

Embodiment 3

[0305] In this example, the immobilization of pollutants in final solid waste obtained after decontamination with the paste according to the invention is investigated. Here it is demonstrated that the clay is essential to act both as a tackifier and as a stain fixative.

[0306] More precisely, in this example it is demonstrated the ability of the paste according to the invention to fix pollutants in the dry paste obtained after the decontamination operation.

[0307] For this, soak 1 g of Kaolinite for sale. Prepare samples with different Cs concentrations, namely: 10 -1 M, 10 -2 M, 10 -3 M and 10 -5 M. The sample was dried until evaporated, then suspended in 100 mL with stirring for 24 h. After 24 h, the solution was filtered and the Cs content was analyzed by atomic absorption spectroscopy, which was then compared with the amount of Cs introduced into each gram of kaolinite. Finally, the Cs content retained by the clay was calculated and expressed in %. The result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com