Separating device and use of a separating device

A separation device, annular disk technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as fracture and annular disk damage, and achieve the effects of avoiding rupture, improving robustness, and improving mechanical vibration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A preferred embodiment and details of the separation device of the present disclosure will be explained in more detail below with reference to the accompanying drawings.

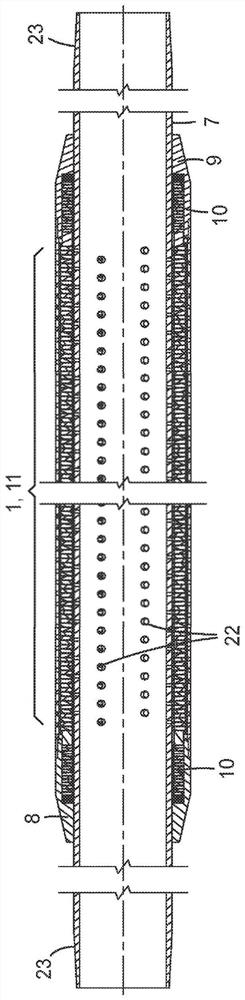

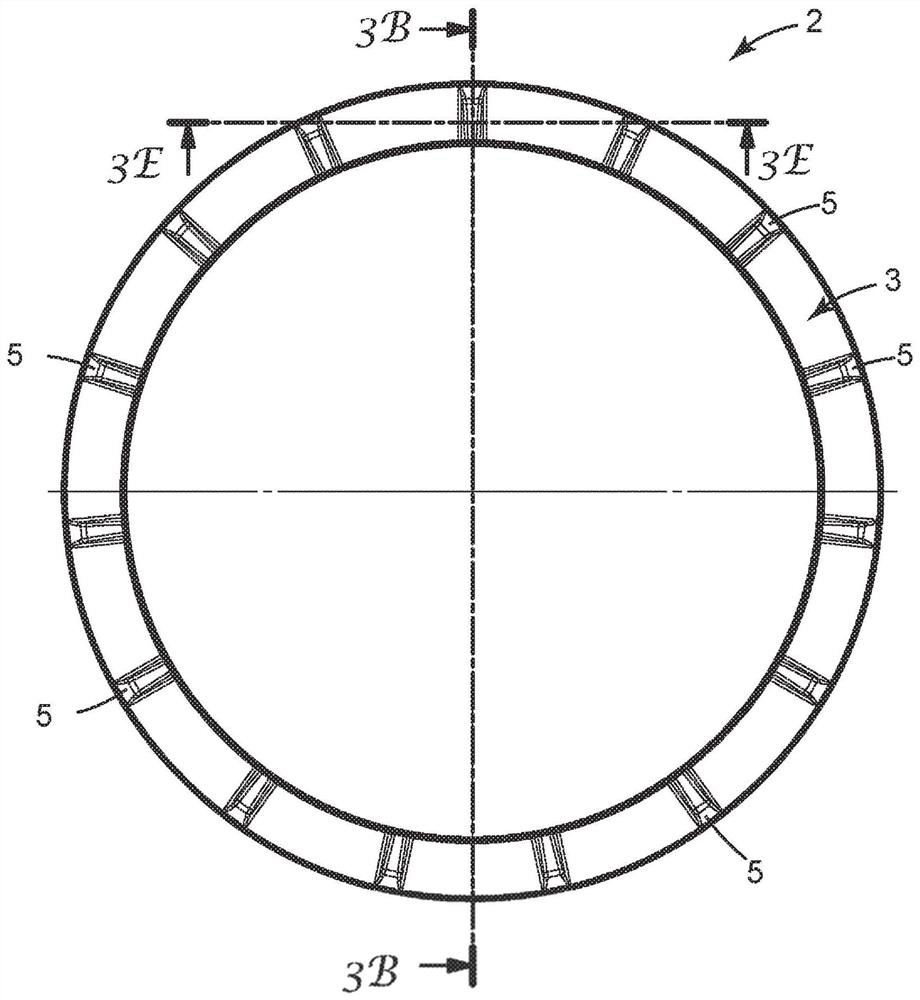

[0034] figure 1 An overall view of the separation device according to the present disclosure is shown. figure 2 A cross-sectional view of the separation device according to the present disclosure is shown. The separation device according to the present disclosure includes a stack of at least three annular discs, which defines a central annular region 1, 11 along the central axis. Preferably, the stack of at least three annular discs is a concentric stack. The separation device includes a perforation tube 7, an annular disk stacked on the perforation tube. The perforation tube 7 having perforations 22 is located within the stacks 1, 11 of the annular disc, and is also referred to below as a base tube. A thread 23 is typically provided at both ends of the perforation tube 7, by which the separation device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com