Finger follower for lobe switching and single source lost motion

A follower and actuation technology, applied in the direction of engine components, combustion engines, engine control, etc., can solve problems such as limited applicability, achieve the effects of eliminating changes in locking or support positions, reducing costs, and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

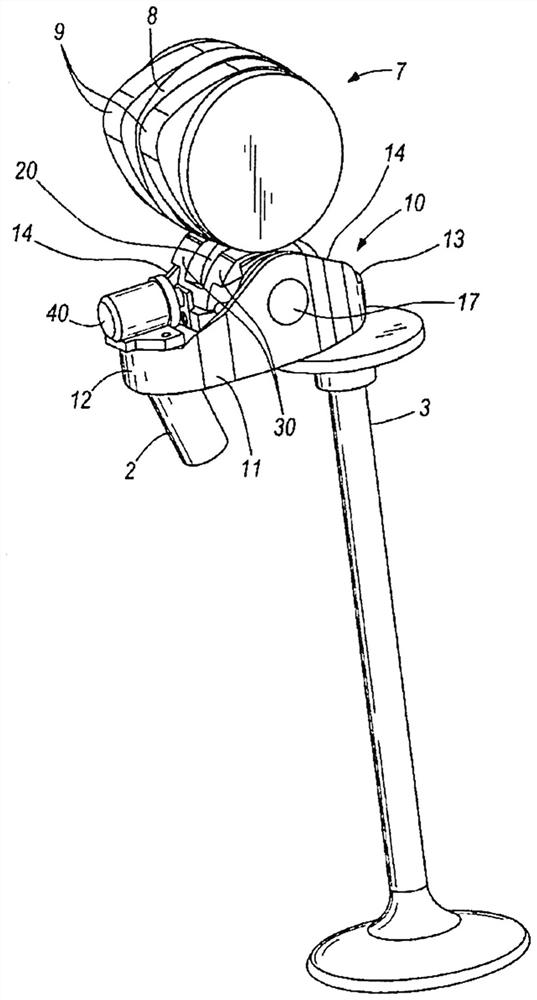

[0039] Figure 4 is a perspective view of a toggle finger follower system 100 assembled according to an example of the present disclosure. Figure 5 is an exploded perspective view of the same system. In particular, the switching finger follower may include a body or housing 400 arranged to support or house various other system components. The body 400 may extend in a longitudinal direction from a motion transfer or valve engagement end 410 adapted to connect or engage with one or more engine valves to a pivot end 420, the pivot end 420 Adapted for connection or engagement with a pivot which may contain HLA. Body 400 may further include a pair of lateral, longitudinally extending arms 402 and 404 defining a lever groove or pocket 406 therebetween. Arms 402 and 404 may include respective pivot pin receiving holes 403 and 405 at valve engaging end 410 to secure lever pivot pin 412 therein. A pair of side roller followers 430 and 434 may be secured to arms 402 and 404 by shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com