Torsional vibration damper with a rotational axis for a powertrain

A technology of torsional vibration damper and axis of rotation, applied in the field of torsional vibration damper, which can solve the problems of expensive, uncompetitive, complicated manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

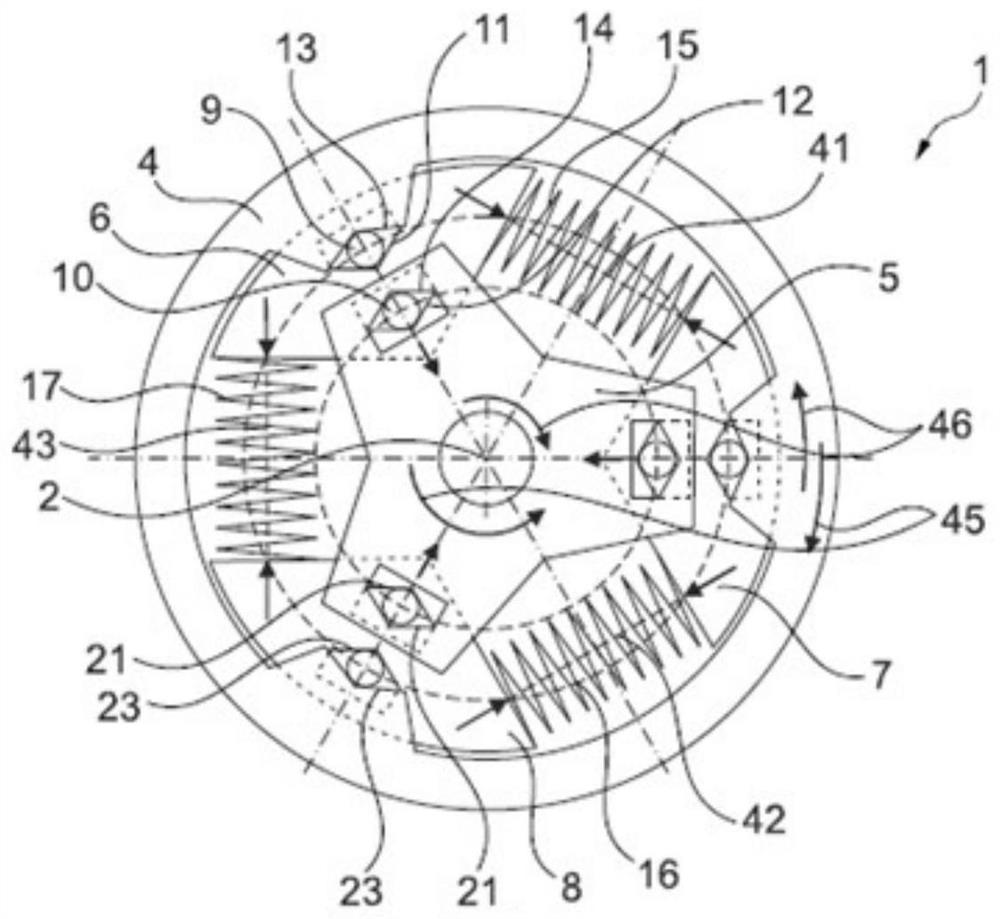

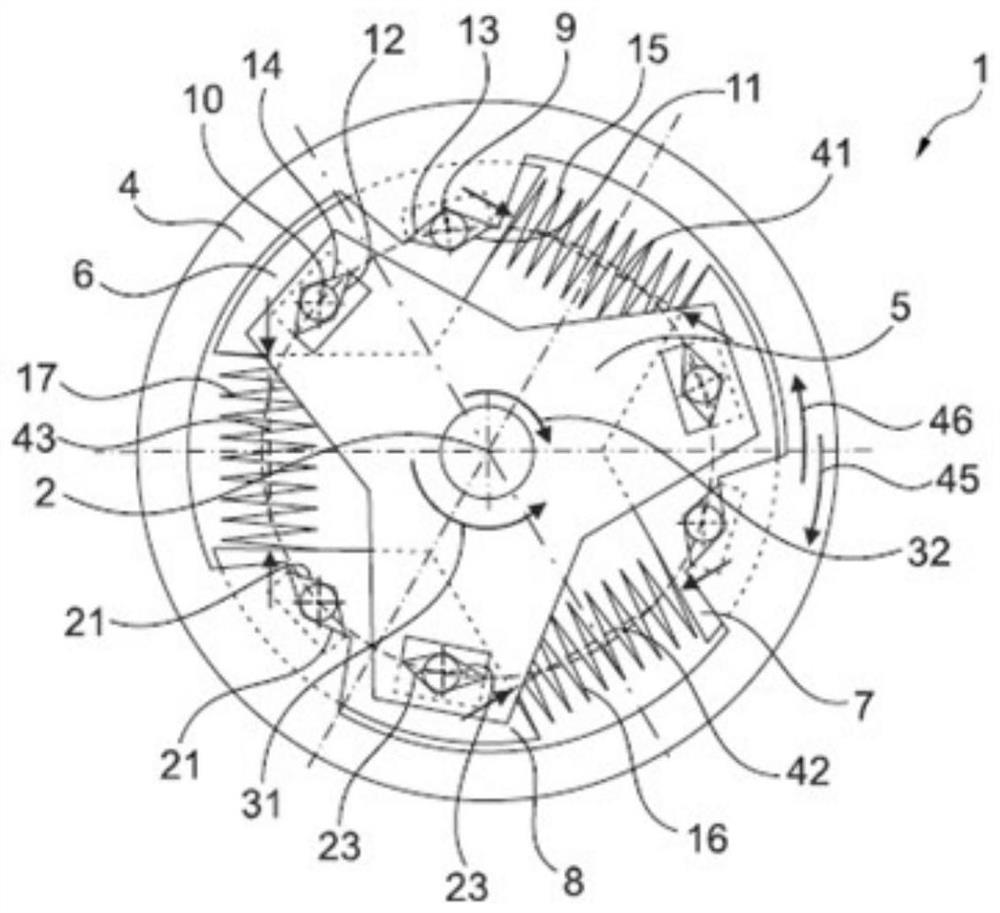

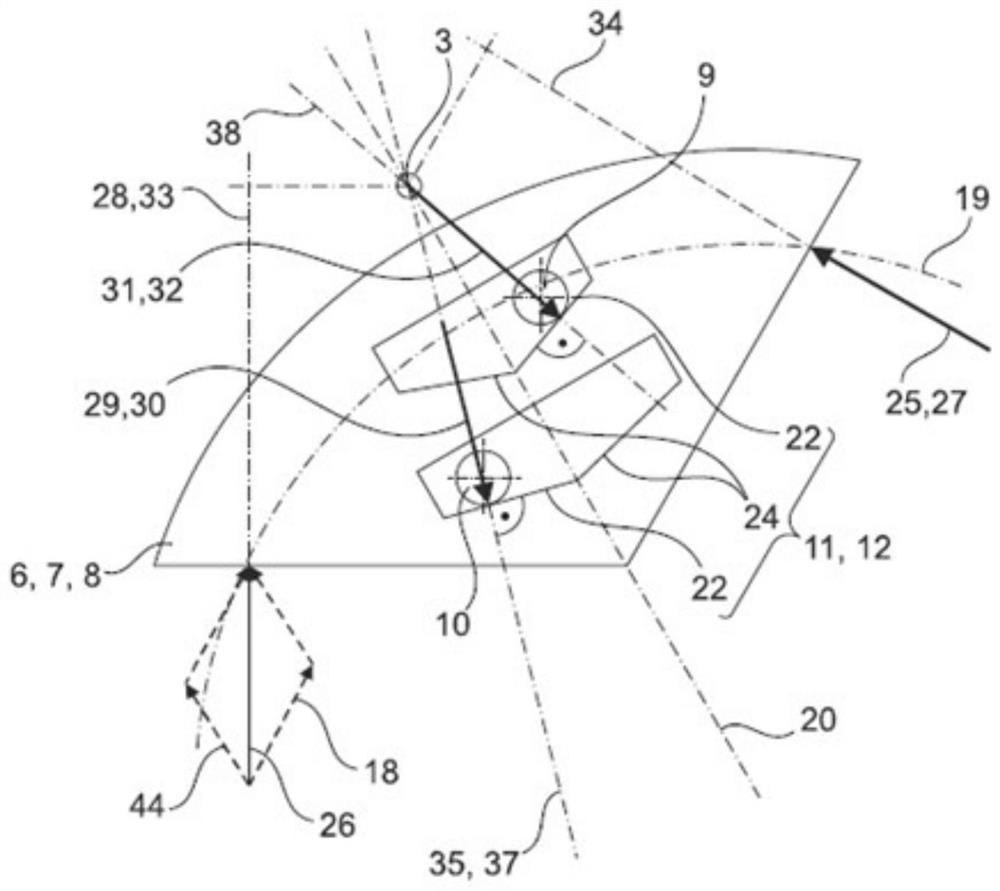

[0080] for example, figure 1 and figure 2 Different embodiments of the torsional vibration damper 1 are each shown in the schematic diagrams, which, for the sake of clarity, are generally described in the same manner and to some extent cross-referenced to the descriptions of the corresponding figures of the same components . Here, the annular disk forms the input side 4 . In the center of the common axis of rotation 2 a further disk element is designed, for example, as an output side 5 . Alternatively, the annular disc is the output side 5 and the disc element is the input side 4 . The above-mentioned variants are described below, where the terms are interchangeable.

[0081] As indicated by the arrows, traction torque 45 may be transferred from input side 4 to output side 5 and thrust torque 46 may be transferred from output side 5 to input side 4 . In one embodiment, the torque directions are set in opposite directions.

[0082]Interposed between the input side 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com