Bearing oiling device for high-end equipment manufacturing

A technology of equipment and bearings, which is applied to the device and coating of the surface coating liquid, which can solve the problem of low oiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

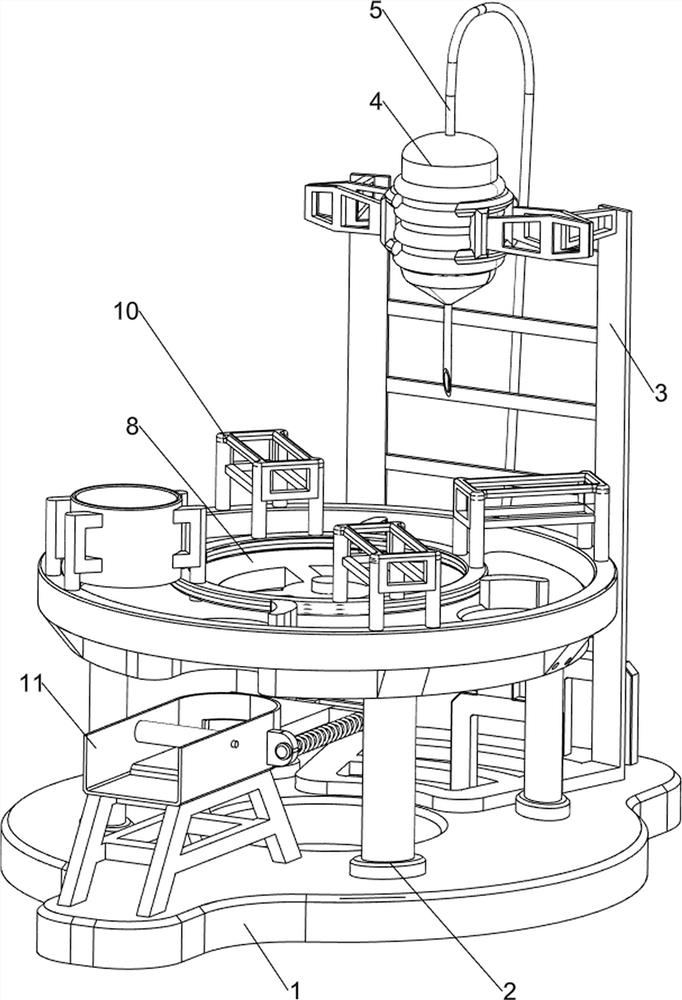

[0060] A bearing oiling device for high-end equipment manufacturing, such as Figure 1-4 As shown, it includes a bottom plate 1, a material rack 2, an oil pot frame 3, an oil pot 4, an air pipe 5, an extruding air pump 6, an air pump frame 7, a material distribution device 8 and a rotating mechanism 9, and the top of the bottom plate 1 is provided with a material Frame 2, the left side of the upper part of the material rack 2 is provided with a discharge port, the right side of the top of the bottom plate 1 is provided with an oiler frame 3, the upper part of the oiler frame 3 is provided with an oiler 4, and the top of the oiler 4 is provided with a gas pipe 5, and the material The right side of the upper part of the frame 2 is provided with an air pump frame 7, and the left side of the air pump frame 7 is provided with an extruding air pump 6. A rotating mechanism 9 is connected between the side and the parts of the distribution device 8 .

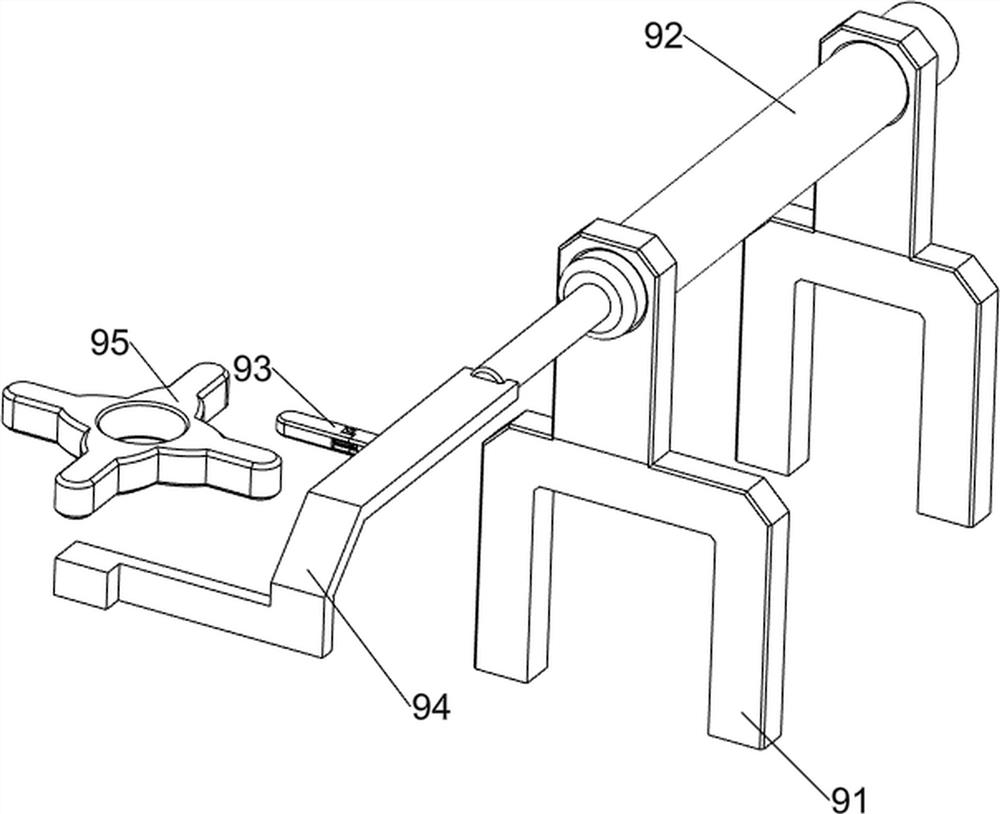

[0061] Distributing device 8 com...

Embodiment 2

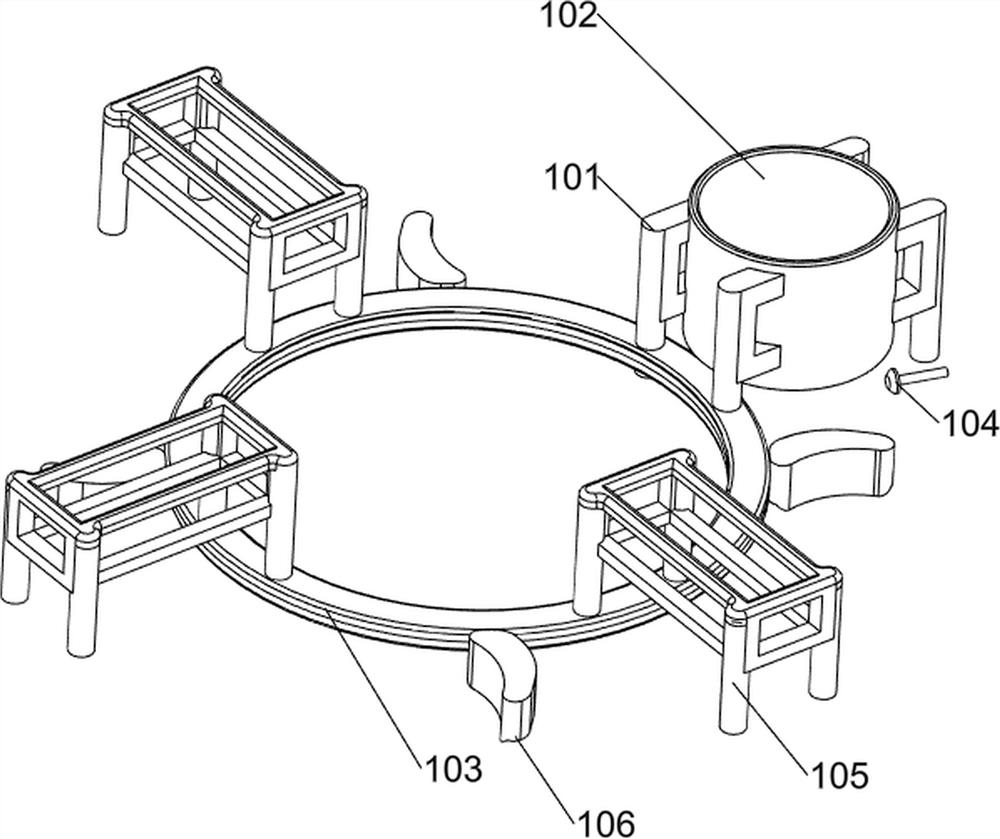

[0065] On the basis of Example 1, such as Figure 5-8As shown, a feeding mechanism 10 is also included, and the feeding mechanism 10 includes a barrel frame 101, a barrel 102, a guide ring 103, a limit post 104, a bracket 105 and a stopper 106, and the top of the material rack 2 is provided with 3 brackets 105, a guide ring 103 is arranged between the bottoms of the brackets 105, two bucket racks 101 are arranged on the left side of the top of the guide ring 103 and the top left side of the material rack 2, and a barrel 102 is arranged between the inner sides of the bucket rack 101, and the upper part of the material rack 2 A limit column 104 is provided, and the limit column 104 is located under the rear side of the barrel 102 , and four stoppers 106 are uniformly provided on the top of the distribution tray 84 .

[0066] People put the bearing in the material cylinder 102, and the bearing falls down onto the distribution tray 84 through the material cylinder 102. When the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com