Cold heading die and cold heading forming process

A cold heading and mold technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problem that it is difficult to meet the mass production of tooth-shaped heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The cold heading die provided in this embodiment is used for tooth-shaped cold heading forming of the head of the bolt.

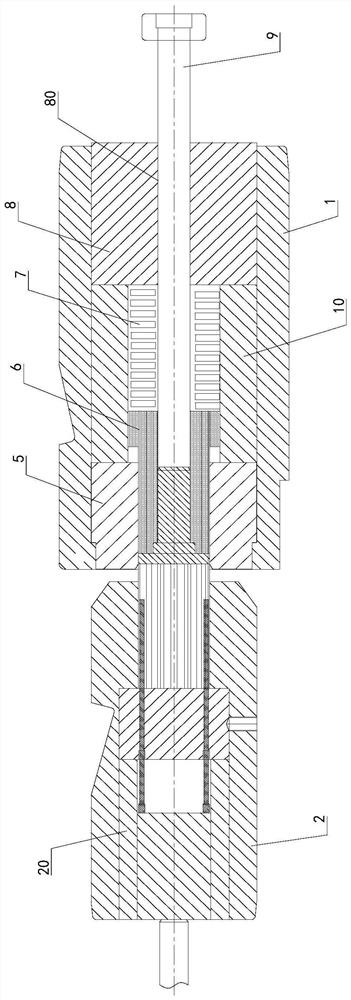

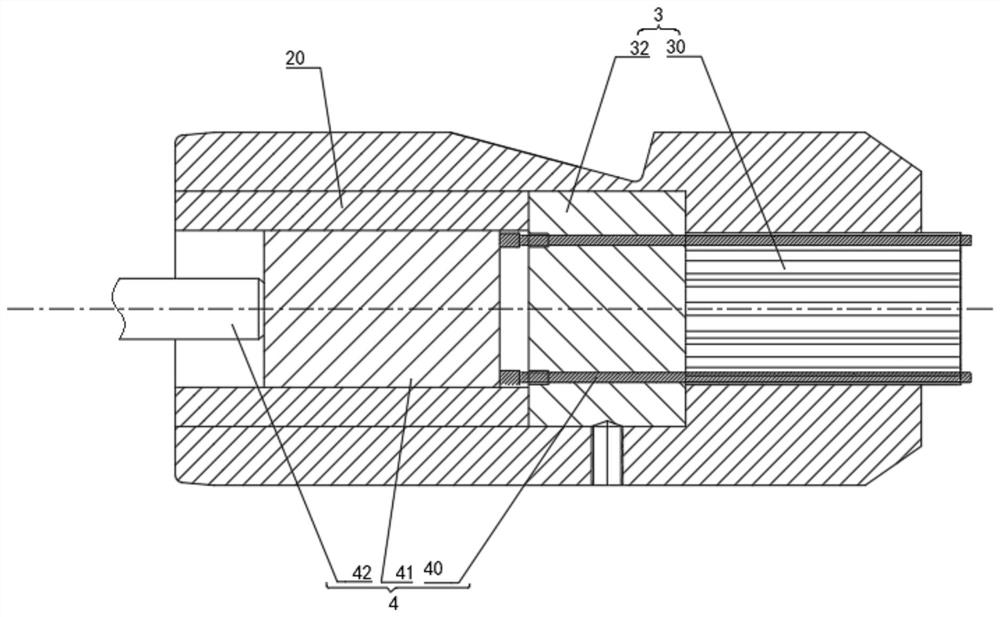

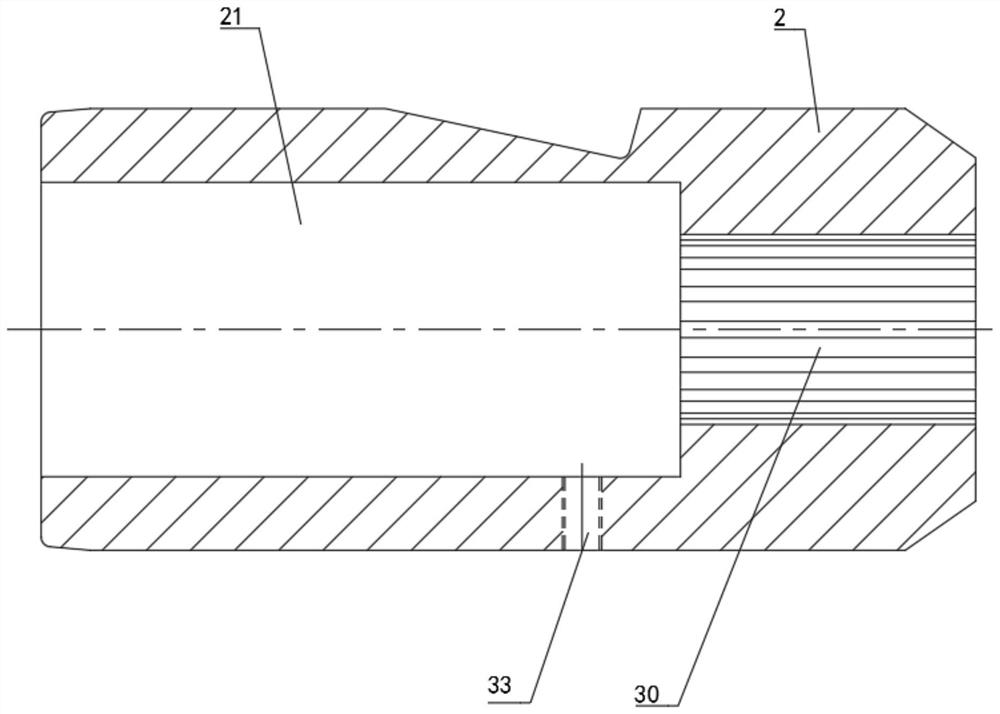

[0064] see Figure 1 to Figure 9 and combine Figure 10 to Figure 12 As shown, the cold heading die provided in this embodiment is used for processing bolts with toothed heads. The cold heading die includes a movable die set 2, a static die set 1, a punch assembly 3 and a waste ejection assembly 4.

[0065] Hereinafter, the above-mentioned components of the cold heading die will be described in detail.

[0066] A tooth-shaped machining hole 50 is formed inside the static mold casing 1 , and a cutting edge 51 is provided on an edge of the tooth-shaped processing hole 50 near the movable mold casing 2 . Wherein, the edges include not only the edges extending in the radial direction of the tooth-shaped processing hole 50 , but also the edges extending in the circumferential direction of the tooth-shaped processing hole 50 . In addition, the cutting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com