Self-adaptive welding tool

A welding tool and self-adaptive technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of poor welding quality and the parts to be welded cannot be in close contact, so as to achieve simple structure, improve welding quality and efficiency , to avoid the effect of positioning failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

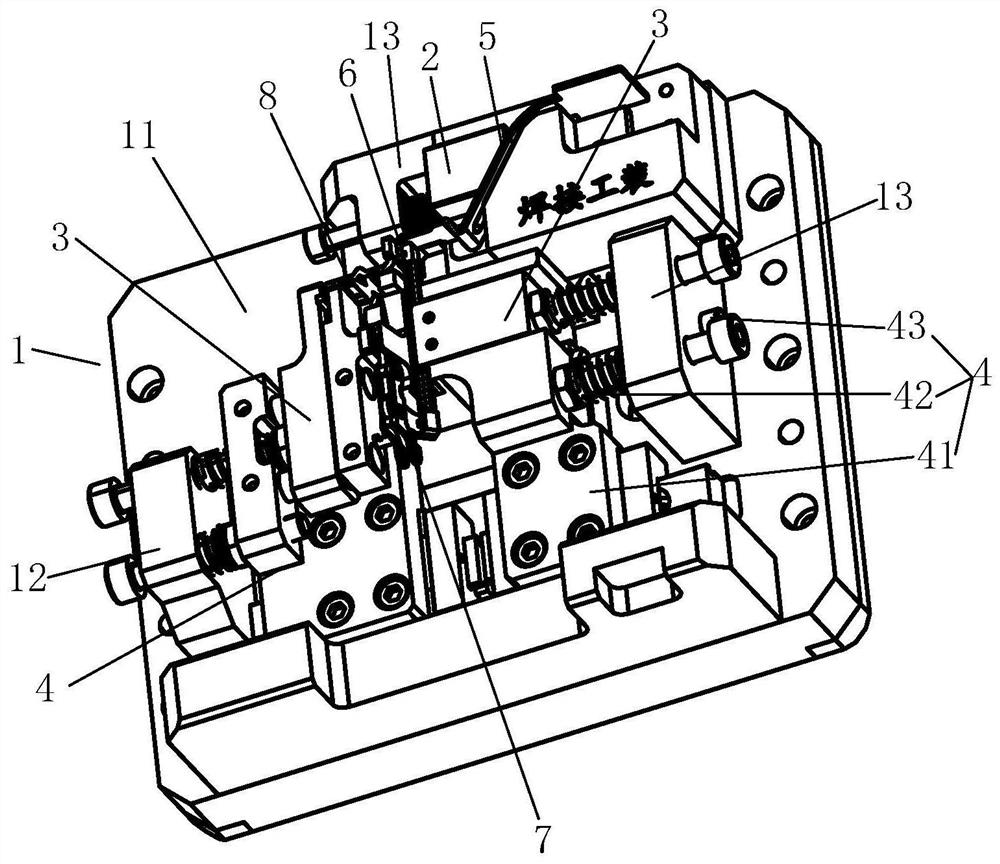

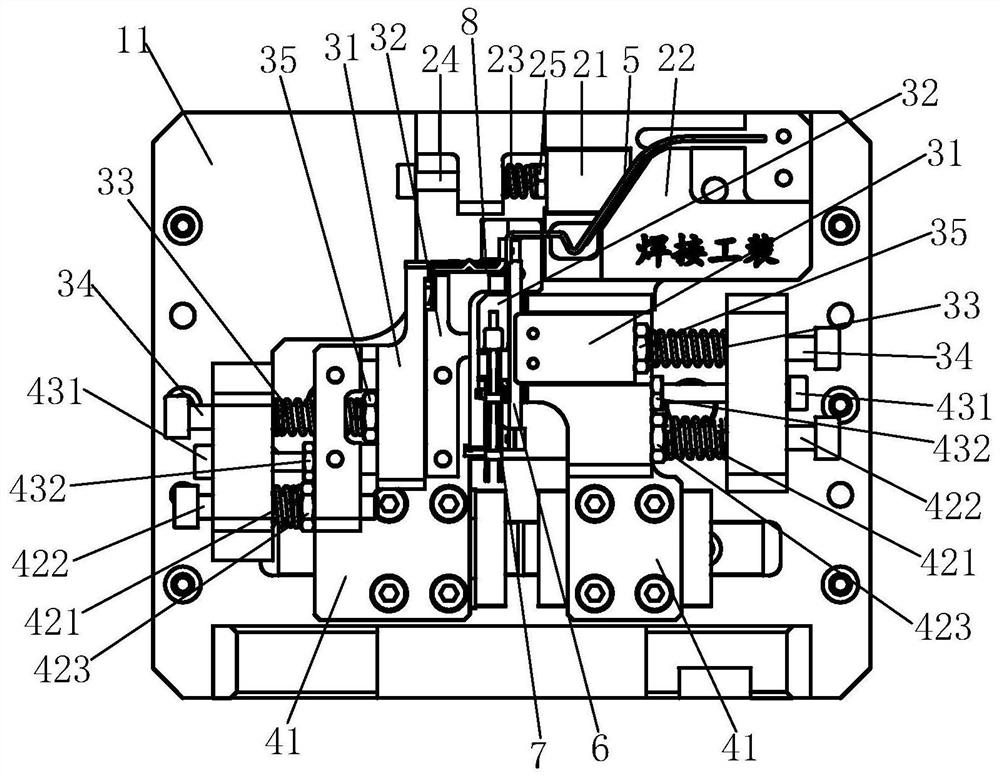

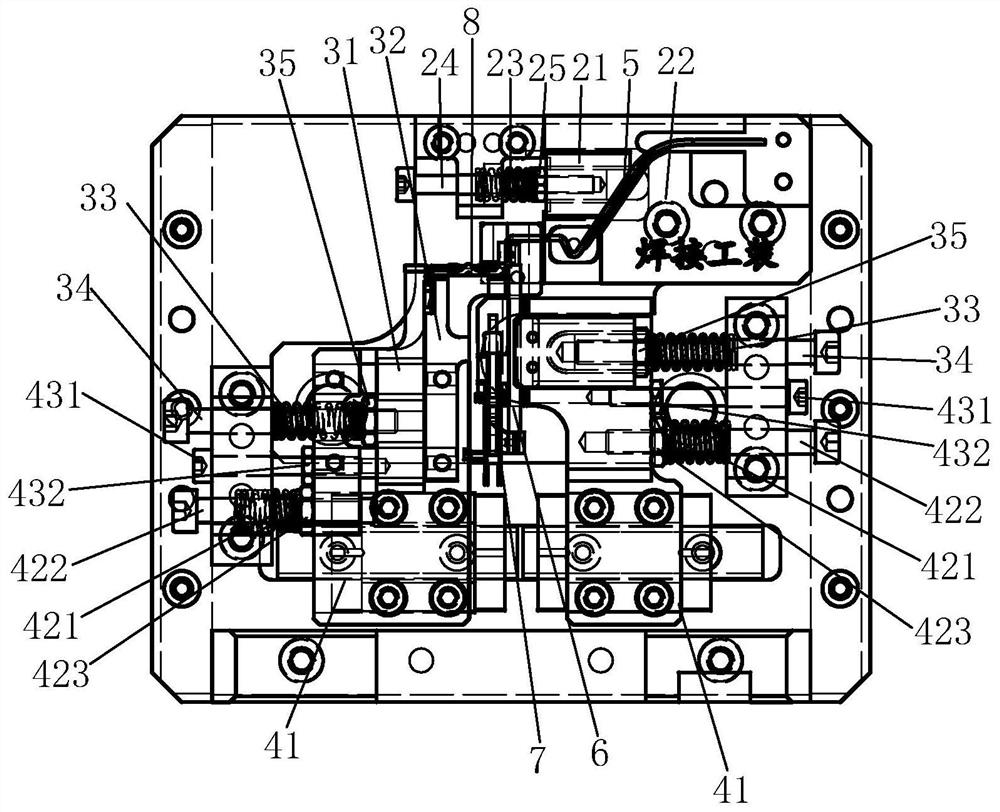

[0028] Examples, see Figure 1-Figure 5 As shown, an adaptive welding tool of the present invention includes a tool body 1, a clamping mechanism A2, and a clamping mechanism B3, and the clamping mechanism A2 is arranged on the tool body 1; it also includes an adaptive mechanism 4, and the adaptive mechanism 4 It includes a sliding part 41 and a spring pressing part 42. The clamping mechanism B3 is arranged on the sliding part 41. The sliding part 41 is slidably connected to the tool body 1, and a spring pressing part 42 is arranged between the two. The elastic preload of the sliding member 41 sliding in a preset direction makes the accessory clamped by the clamping mechanism B3 be in a position suitable for welding with the accessory clamped by the clamping mechanism A2.

[0029] In this embodiment, the present invention further includes a pre-positioning component 43, which is arranged on the tool body 1 and restricts the movement of the sliding member 41 in a direction oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com