Pile testing method for cast-in-situ bored pile

A technology for drilling cast-in-place piles and test piles, which is used in the testing of foundation structures, construction, and foundation structure engineering, etc. The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

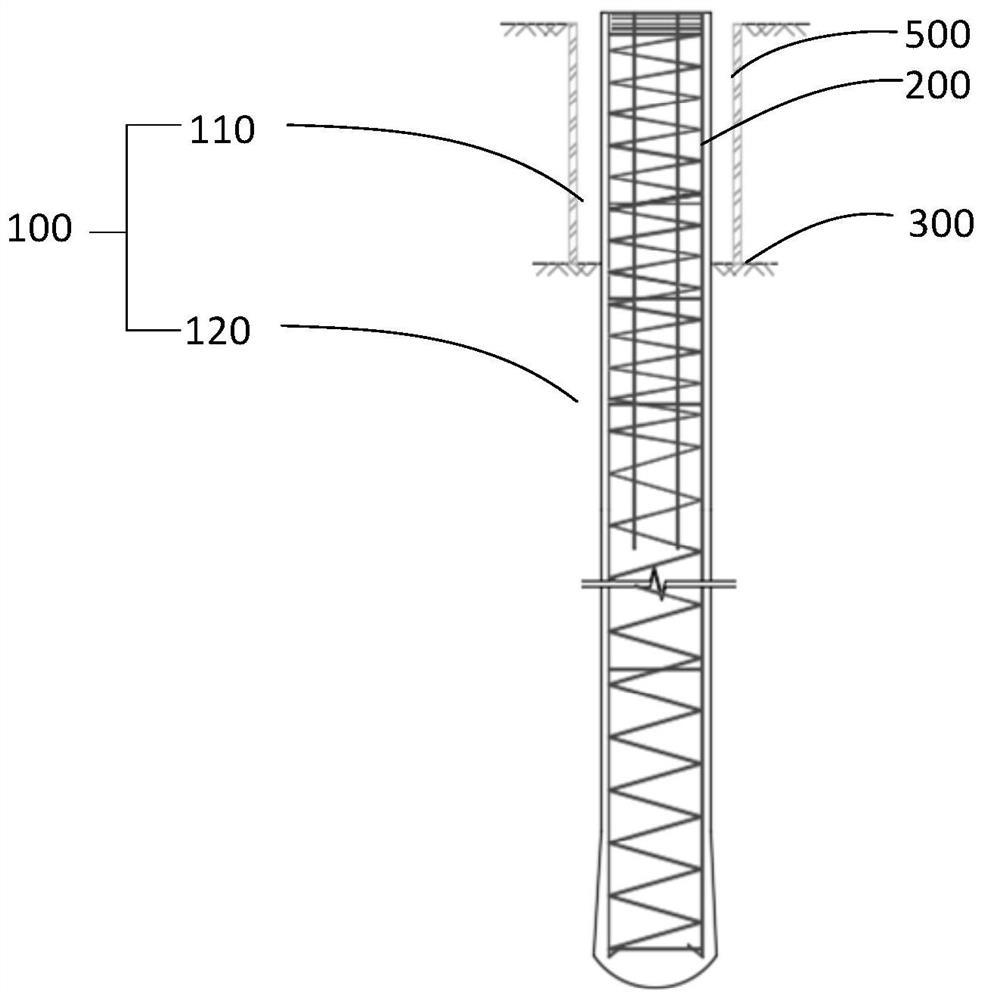

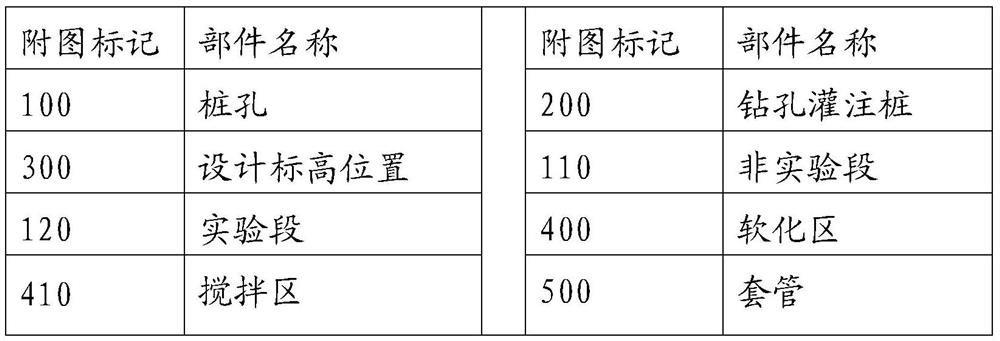

[0035] The first embodiment of the present application discloses a pile test method for bored piles, which is used in the pile test stage of bored piles 200 . Please combine figure 1 Shown understand the pile test method of the application bored cast-in-place pile, the test pile method of described bored cast-in-place pile comprises the steps:

[0036] S110. Drilling the pile hole 100, and pouring the bored cast-in-situ pile 200 in the pile hole 100, the pile hole 100 has a design elevation position 300, and the pile hole 100 includes: the upper side of the design elevation position 300 The non-experimental section 120, the experimental section 120 located at the lower side of the design elevation position 300; first carry out the drilling of the pile hole 100 on the ground, after the drilling, carry out the pouring of the bored pile, and first carry out the pouring of the bored pile 200 The purpose of pouring is to prevent the soil on the inner wall of the pile hole 100 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com