Rapid assembling structure of modular wallboards

An assembly structure and modular technology, applied in the direction of walls, building components, building structures, etc., can solve the problems that wall panels cannot be reused, and the work efficiency of wall manufacturing and wall panel replacement is low, so as to save costs and meet the needs of users. Requirements, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

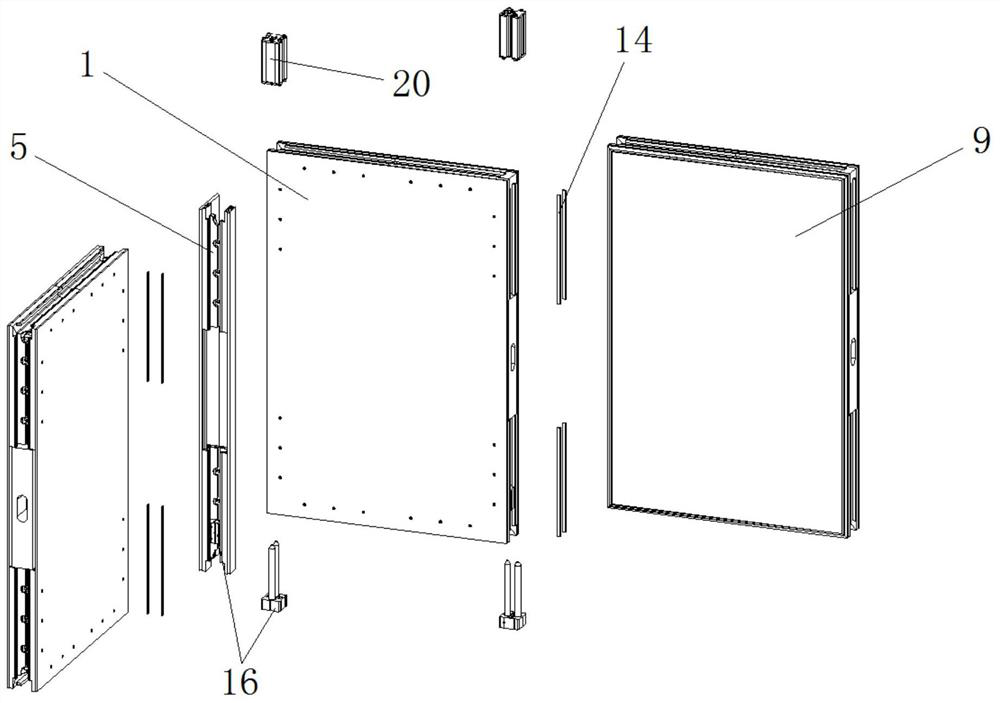

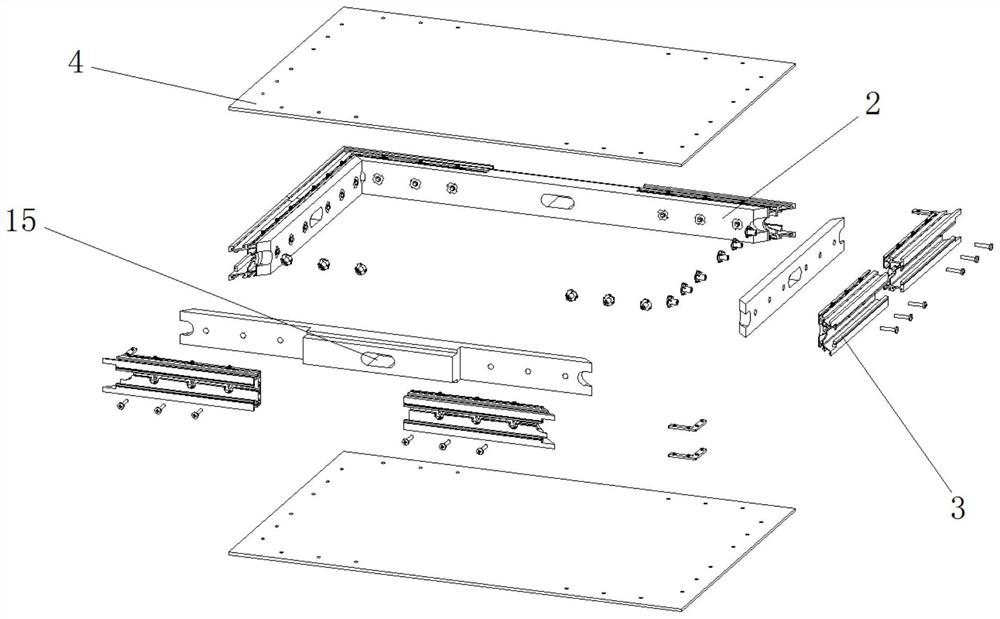

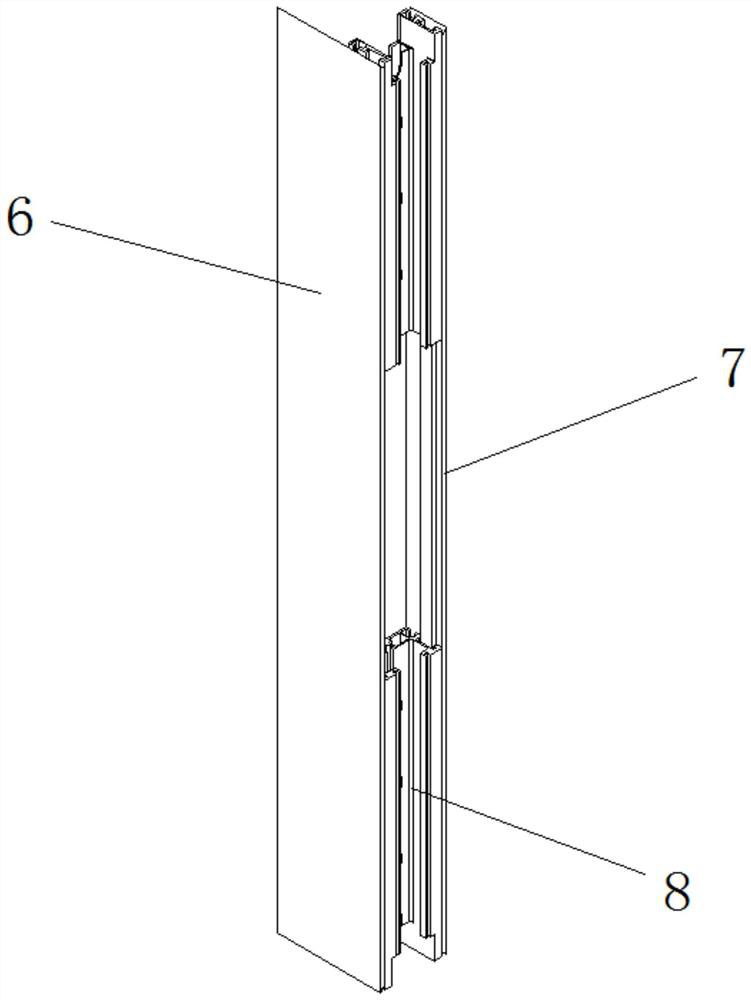

[0025] Such as Figure 1-7 As shown, a rapid assembly structure of a modular wall panel includes several wall panel main bodies 1, the wall panel main body 1 includes a central frame 2, the central frame 2 is formed by bonding four frame bars, and the surroundings of the central frame 2 are connected with The grooved frame bar 3 is provided with a connecting groove on the outer surface of the grooved frame bar 3, and the adjacent wallboard main bodies 1 are connected into one body by inserting connecting pieces in two adjacent connecting grooves. The front and rear of the central frame 2 Panels 4 are respectively glued on the end surfaces, and the outer edges of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com