Direct-acting type direct-current relay with movable contact spring

A technology of DC relays and moving reeds, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as upper circlip breakage, product failure, and lower circlip breakage, etc., to avoid impact and eliminate products. Ineffective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

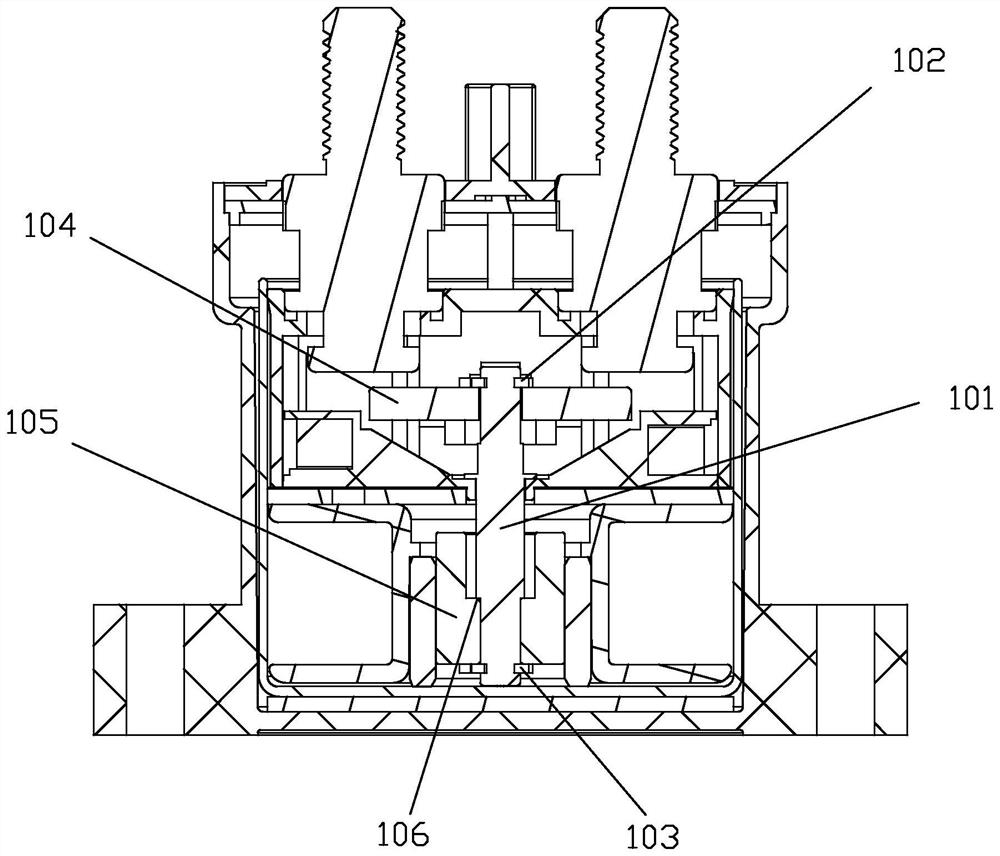

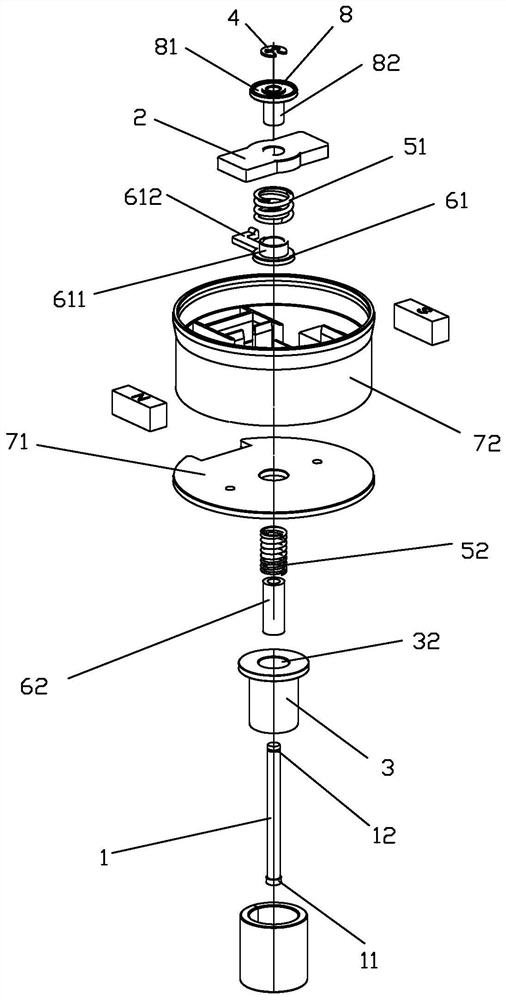

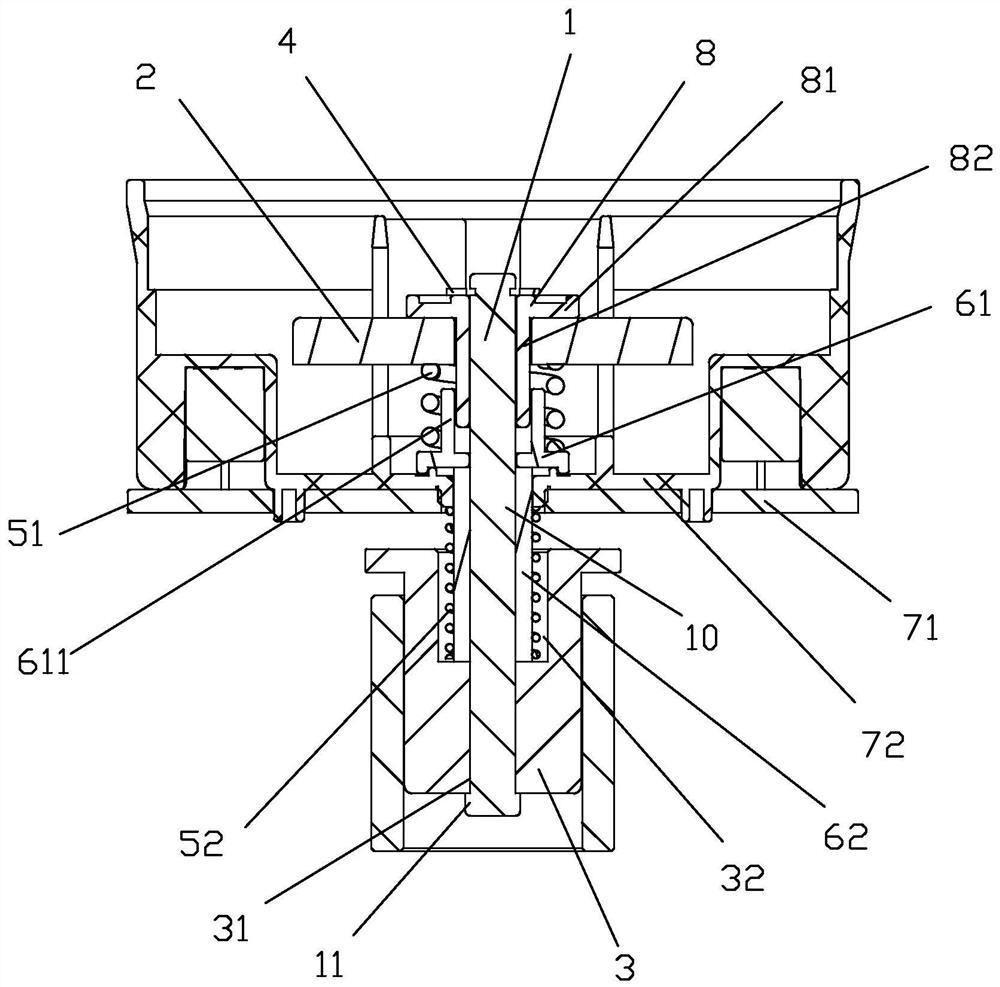

[0030] see Figure 2 to Figure 7As shown, a moving reed direct-acting DC relay of the present invention includes a moving assembly 10 assembled by a push rod 1, a moving reed 2 and a moving iron core 3; the moving assembly 10 also includes an upper Circlip 4 and contact pressure spring 51, the moving reed 2 is movably socketed on the top of the push rod 1 through the upper circlip 4 and contact pressure spring 51, so as to realize overtravel by using the contact pressure spring; Circlip 4 is clamped and fixed on the top of push rod 1 through the card slot 12 at the top of push rod 1 and is limited on the top of the moving reed 2, and the contact pressure spring 51 is fitted on the moving reed 2 The bottom surface of the moving iron core 3 is provided with an iron core hole 31 that can be inserted into the push rod; The convex edge 11 of the core hole 31, the push rod 1 is inserted into the iron core hole 31 of the moving iron core 3 from bottom to top, the convex edge 11 of t...

Embodiment 2

[0047] see Figure 8 , Figure 9 As shown, the difference between the moving reed direct-acting DC relay of the present invention and the first embodiment is that the moving component does not use the upper retaining spring, but uses the nut 41, and the nut 41 is pushed through the push rod 1. The top external thread 13 is connected and fixed on the top of the push rod 1 and is limited on the top of the moving reed 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com