MXene composite fiber reinforced graphene aerogel wave-absorbing material and preparation method thereof

A technology of graphene airgel and graphene hydrogel, which is applied in the field of wave-absorbing materials, can solve problems such as high conductivity, impedance mismatch, and unfavorable impedance matching, and achieve wide effective absorption bandwidth, strong absorbing loss, The effect of improving the electromagnetic wave loss ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention provides a preparation method of MXene composite fiber reinforced graphene airgel wave-absorbing material, comprising the following steps:

[0030] Step 10) preparing MXene composite fiber;

[0031] Step 20) configure graphene oxide water dispersion solution;

[0032] Step 30) adding the MXene composite fiber to the graphene oxide aqueous dispersion, then adding a reducing agent for high-speed dispersion to obtain the MXene composite fiber-graphene oxide aqueous dispersion;

[0033] Step 40) putting the MXene composite fiber-graphene oxide water dispersion solution into the reactor, and obtaining the MXene composite fiber reinforced graphene hydrogel by hydrothermal self-assembly reaction;

[0034] Step 50) Put the MXene composite fiber reinforced graphene hydrogel into liquid nitrogen to pre-freeze, and then perform freeze-drying treatment to obtain the MXene composite fiber reinforced graphene airgel wave-absorbing material.

...

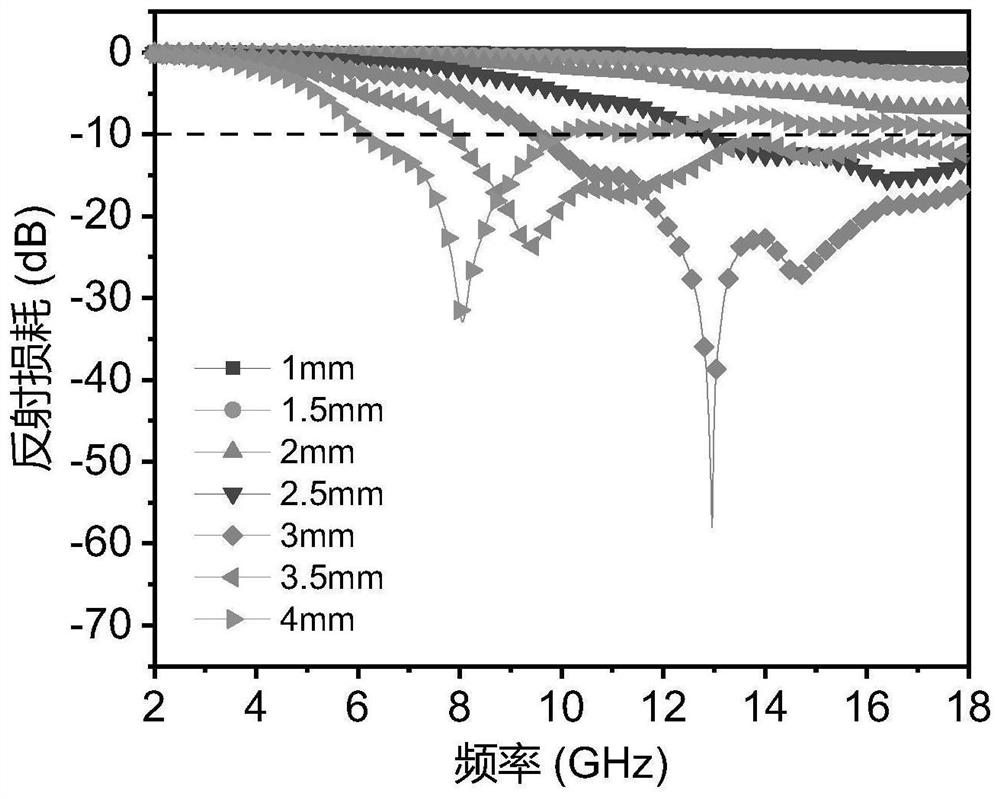

Embodiment 1

[0051] The following steps were used to prepare MXene composite fiber-reinforced graphene airgel absorbing material:

[0052] (1) Configure MXene water dispersion solution, the MXene used is Ti 3 C 2 T x , the concentration is 5mg / mL; configure the graphene oxide aqueous dispersion solution, the concentration is 2mg / mL; configure the cellulose aqueous dispersion solution, the cellulose used is carboxymethylated cellulose, the diameter of the cellulose is about 3μm, and the concentration is 1mg / mL .

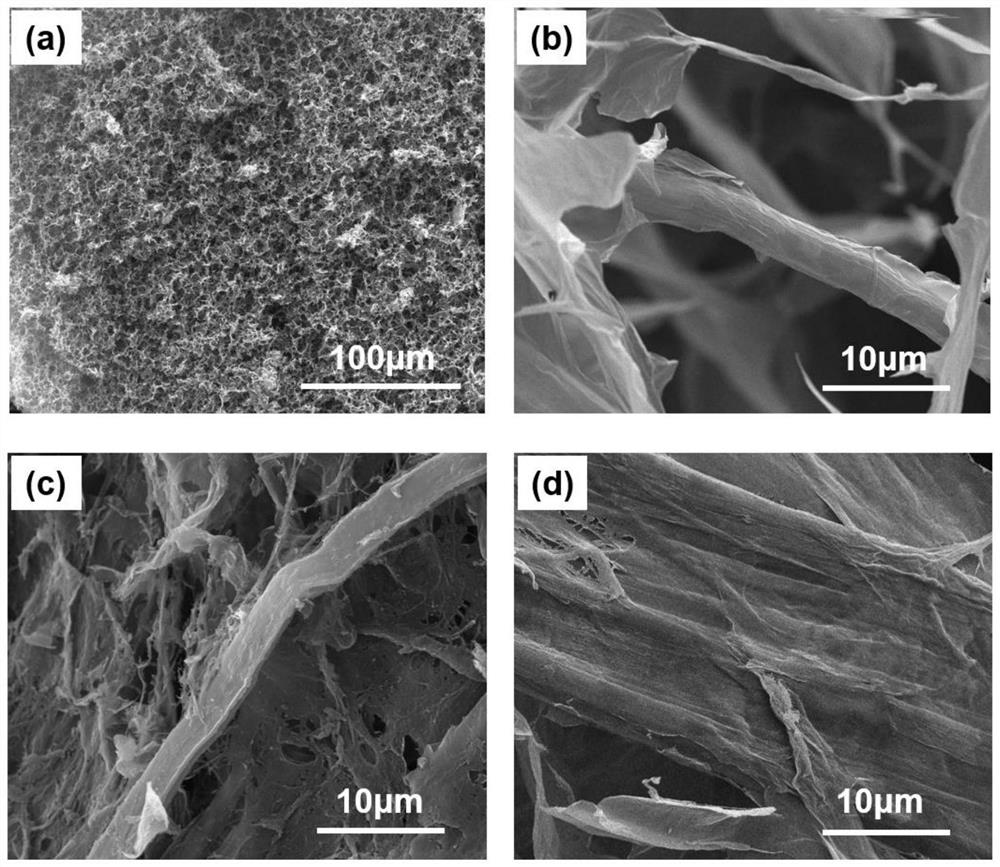

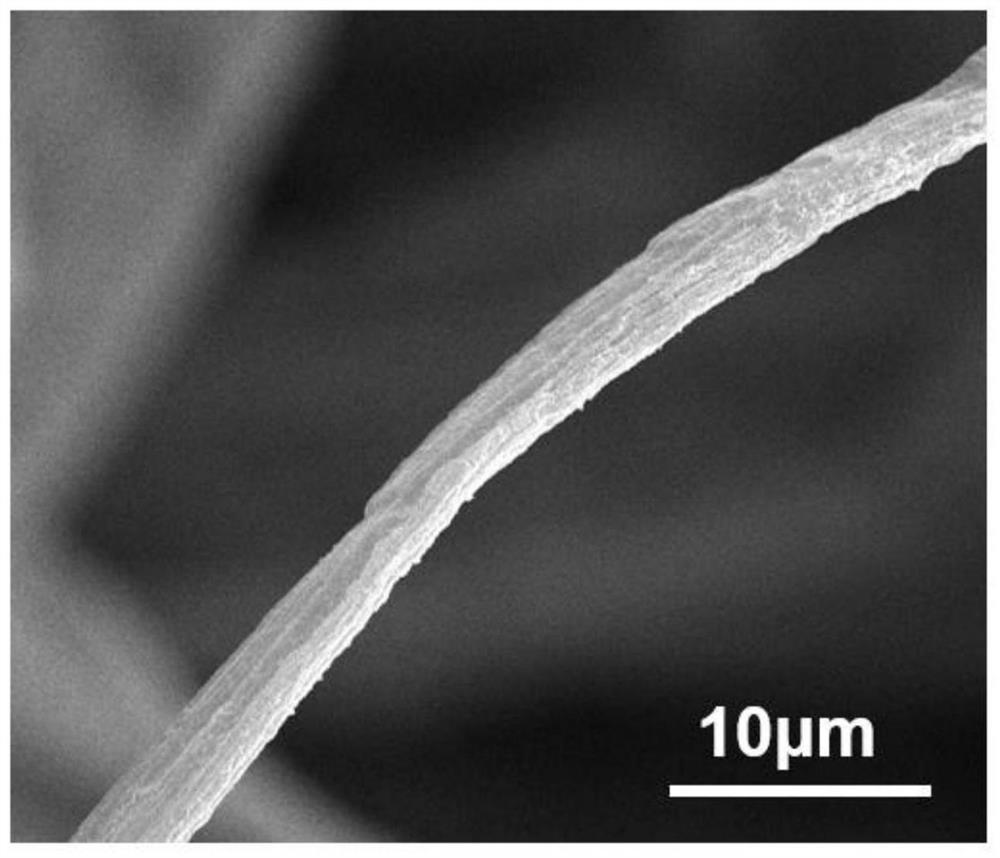

[0053] (2) Mix the MXene water-dispersed solution and the cellulose water-dispersed solution with a solute mass ratio of 1:10, and keep stirring, the stirring speed is 500rpm, and the stirring time is 0.5h; then use deionized water to wash 5 times, And carry out centrifugation and filtration to obtain MXene composite fibers, such as figure 2 shown.

[0054] (3) Add the MXene composite fiber to the graphene oxide water dispersion solution, and then add the reducing agent acco...

Embodiment 2

[0061] The following steps were used to prepare MXene composite fiber-reinforced graphene airgel absorbing material:

[0062] (1) Configure MXene water dispersion solution, the MXene used is Ti 3 C 2 T x, the concentration is 10mg / mL; configure the graphene oxide aqueous dispersion solution, the concentration is 5mg / mL; configure the cellulose aqueous dispersion solution, the cellulose used is carboxymethylated cellulose, the diameter of the cellulose is 5μm, and the concentration is 2mg / mL .

[0063] (2) Mix the MXene water-dispersed solution and the cellulose water-dispersed solution with a solute mass ratio of 1:5, and keep stirring, the stirring speed is 800rpm, and the stirring time is 1h; then use deionized water to wash 5 times, and Perform centrifugation and filtration to obtain MXene composite fibers.

[0064] (3) Add the MXene composite fiber to the graphene oxide aqueous dispersion solution, and then add the reducing agent according to the mass ratio of the amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com