Production method of tempering type low-yield-ratio bridge steel

A production method and low yield ratio technology, which is applied in the production field of tempered low yield ratio bridge steel, to achieve the effect of low alloy cost and reduced energy consumption of steel burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

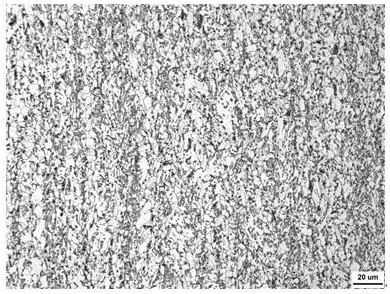

Image

Examples

Embodiment 1

[0020] Embodiment 1: The production method of 6mm low yield strength ratio Q420qE steel plate.

[0021] Chemical composition of steel: C=0.08%, Si=0.24%, Mn=1.56%, P=0.010%, S=0.001%, Alt=0.030%, Nb=0.015%, Ti=0.015%, Cr=0.18% , Mo=0.10%, Cu=0.17%, Pcm=0.19%, the balance is Fe and unavoidable impurities.

[0022] The production process steps and parameters of steel are:

[0023] (1) Heating: The billet is directly loaded, the furnace charging temperature: 516°C, the furnace temperature: 1140~1190°C, and the total time in the furnace: 140min.

[0024] (2) Rough rolling: the intermediate billet is set at 55mm, the starting rolling temperature is 1150°C, the final rolling temperature is 990°C, 7 passes, and the cumulative reduction rate is 69.5%.

[0025] (3) Finish rolling: the starting rolling temperature is 915°C, the final rolling temperature is 805~825°C, 7 passes, and the cumulative reduction rate is 89.1%.

[0026] (4) Cooling: The starting cooling temperature is 810~82...

Embodiment 2

[0029] Embodiment 2: The production method of 20mm low yield strength ratio Q420qE steel plate.

[0030] Chemical composition of steel: C=0.07%, Si=0.26%, Mn=1.54%, P=0.010%, S=0.001%, Alt=0.032%, Nb=0.018%, Ti=0.016%, Cr=0.17% , Mo=0.11%, Cu=0.18%, Pcm=0.18%, the balance is Fe and unavoidable impurities.

[0031] The production process steps and parameters of steel are:

[0032] (1) Heating: The billet is directly charged, the furnace charging temperature is 532°C, the furnace temperature is 1160~1188°C, and the total time in the furnace is 162min.

[0033] (2) Rough rolling: the intermediate billet is set at 80mm, the rolling start temperature is 1172°C, the final rolling temperature is 992°C, 7 passes, and the cumulative reduction rate is 69.2%.

[0034] (3) Finish rolling: the starting rolling temperature is 880°C, the final rolling temperature is 801~822°C, 7 passes, and the cumulative reduction rate is 75%.

[0035] (4) Cooling: The starting cooling temperature is 796...

Embodiment 3

[0038] Embodiment 3: The production method of 50mm low yield strength ratio Q420qE steel plate.

[0039] Chemical composition of steel: C=0.08%, Si=0.29%, Mn=1.56%, P=0.010%, S=0.001%, Alt=0.040%, Nb=0.022%, Ti=0.015%, Cr=0.18% , Mo=0.10%, Cu=0.19%, Pcm=0.19%, the balance is Fe and unavoidable impurities.

[0040] The production process steps and parameters of steel are:

[0041] (1) Heating: The billet is directly charged, the furnace charging temperature is 572°C, the furnace temperature is 1172~1188°C, and the total time in the furnace is 176min.

[0042] (2) Rough rolling: the intermediate billet is set at 125mm, the starting rolling temperature is 1176°C, the final rolling temperature is 995°C, 5 passes, and the cumulative reduction rate is 51.9%.

[0043] (3) Finish rolling: start rolling temperature 840°C, finish rolling temperature 790~800°C, 9 passes, cumulative reduction rate 60%.

[0044] (4) Cooling: The starting cooling temperature is 775~798°C, the cooling rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com