Real-time monitoring terminal for industrial boiler

A technology for real-time monitoring and industrial boilers, applied in the direction of controlling combustion, combustion methods, combustion chambers, etc., can solve the problems of small real-time monitoring terminal force, inconvenient use of industrial boilers, and inability to adjust boilers, etc., to achieve intelligent control and convenience The effect of operation and avoiding waste of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

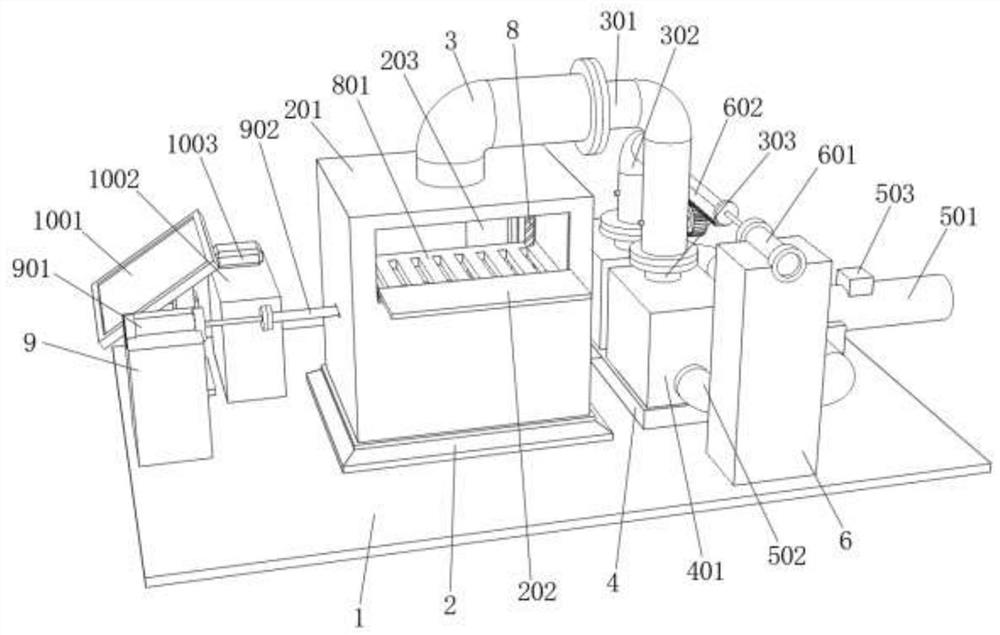

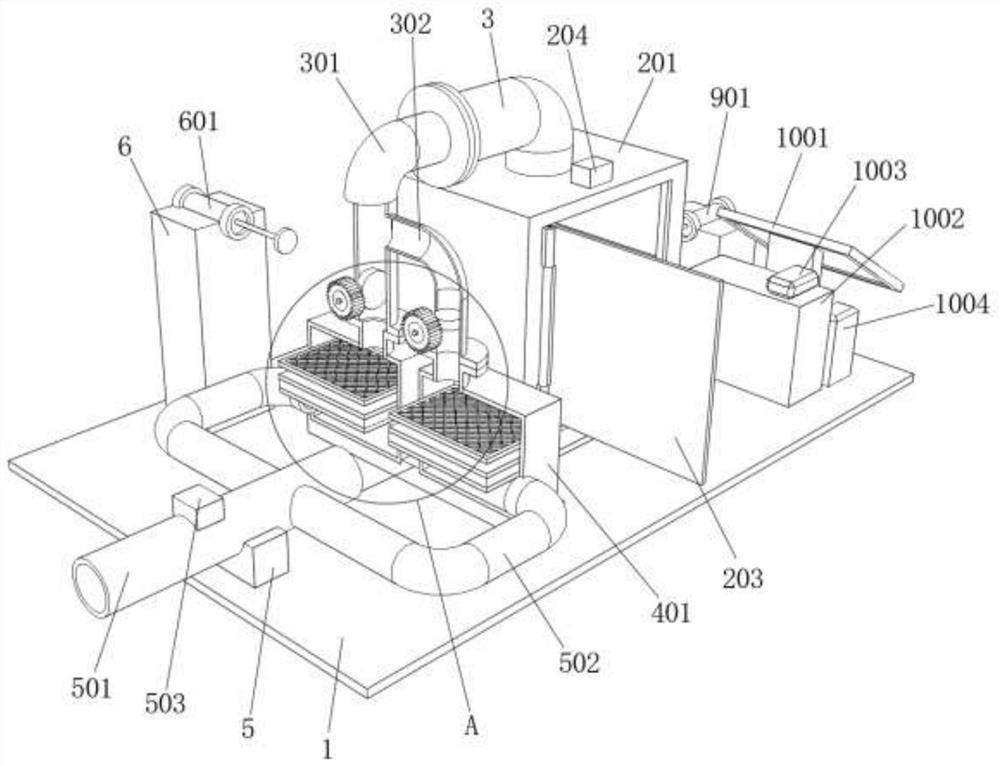

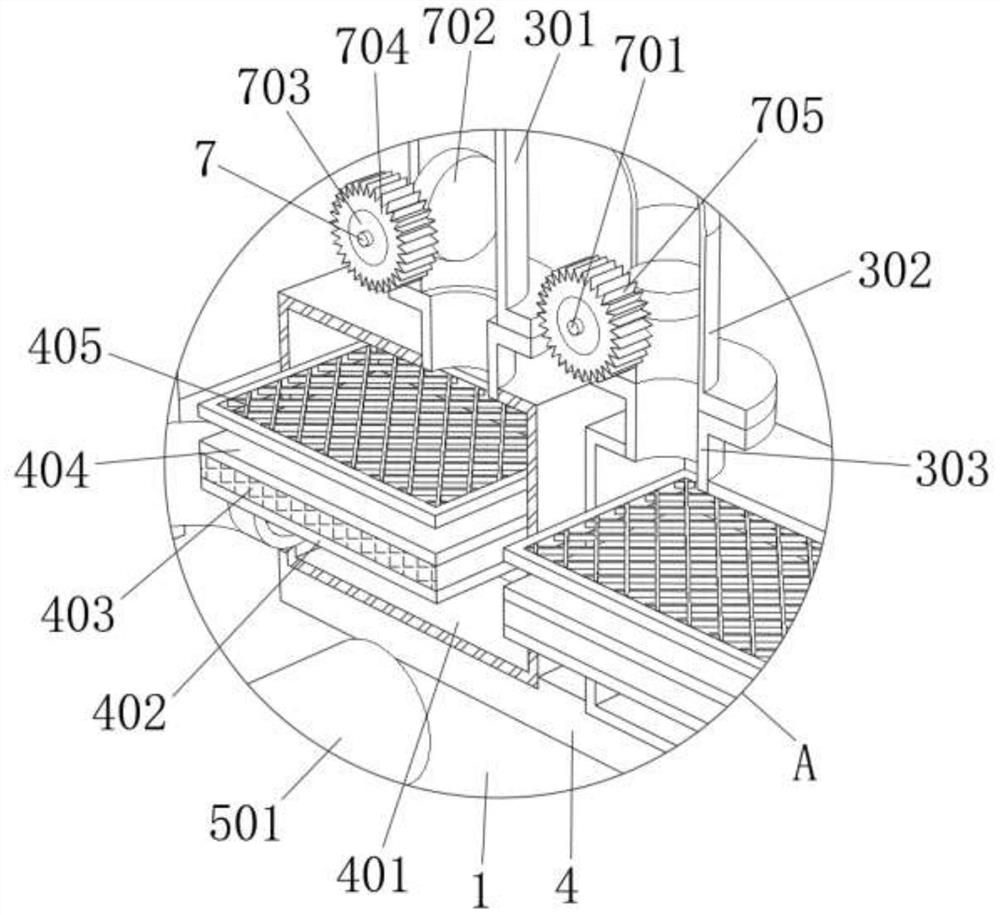

[0036] refer to Figure 1-Figure 5 , an industrial boiler real-time monitoring terminal, comprising a base plate 1, the upper surface of the base plate 1 is fixed with a heat-insulating base 2 by bolts, the upper surface of the heat-insulating base 2 is fixed with a boiler body 201 by bolts, and the outer walls of both sides of the boiler body 201 are provided with seals The first sealing plate 202 and the second sealing plate 203 are connected to one side of the two sealing ports respectively, and the top of the inner wall of the boiler body 201 is provided with a temperature sensor 204, wherein the model of the temperature sensor 294 is ATS1-82, and the temperature sensor 204 cooperates with the control mechanism, so that the controller 1004 can monitor the temperature in the boiler body 201 in real time through the temperature sensor 204, wherein the model of the controller 1004 is DATA-7311, and the bottom of the inner wall of the boiler body 201 is welded with multiple gui...

Embodiment 2

[0040] refer to Figure 6-Figure 7, the upper surface of the fixed block 1002 is fixed with a mobile hard disk 11 by bolts, the upper surface of the boiler body 201 is fixed with an installation block 1101 by bolts, the upper surface of the installation block 1101 is fixed with a speaker 1102 and a flashing light 1103 by bolts, and the mobile hard disk 11, speaker 1102 The speaker 1102 and the flashing light 1103 are electrically connected to the output terminal of the controller 1004, and the speaker 1102 and the flashing light 1103 cooperate to form a warning mechanism. Warning, convenient for nearby workers to check the boiler in time, repair and maintain it, and avoid damage to the boiler. The top of the inner wall of the boiler body 201 is fixed with a protective net 1104 by bolts, and the protective net 1104 is located at the bottom of the installation port of the boiler body 201 The protective net 1104 intercepts the solid matter in the combustion fuel, fully burns it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com