Calibration system and measurement method thereof

A calibration system and measurement method technology, applied in the field of precision measurement instruments, can solve problems such as low efficiency, inability to obtain included angle data, and difficulty in achieving ideal results, and achieve the effect of improving efficiency and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

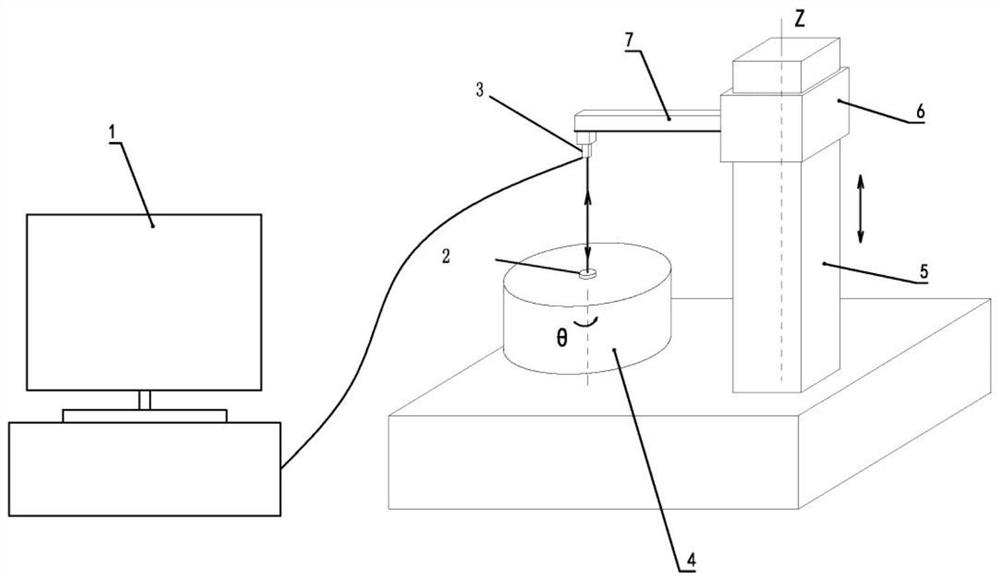

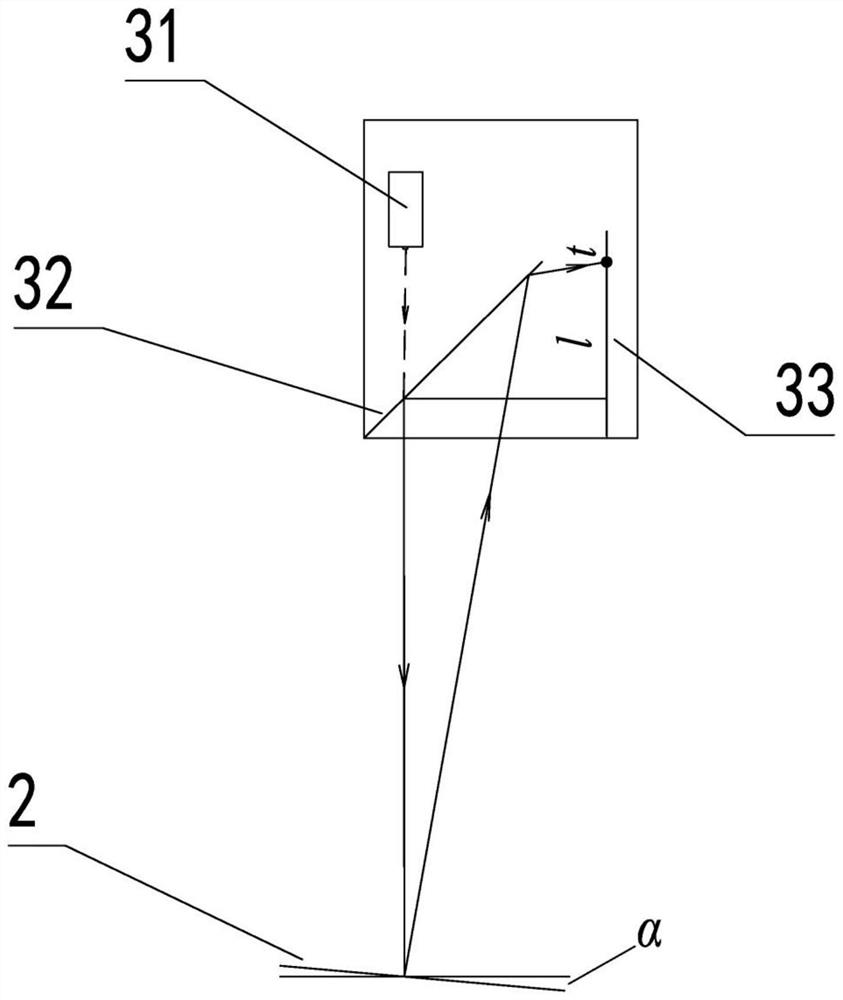

[0030] like Figure 2 to Figure 5 As shown, a calibration system includes three parts, an optical transmitting and receiving device 3, a mirror 2 and a computing unit 3, which work together to realize the acquisition of the included angle.

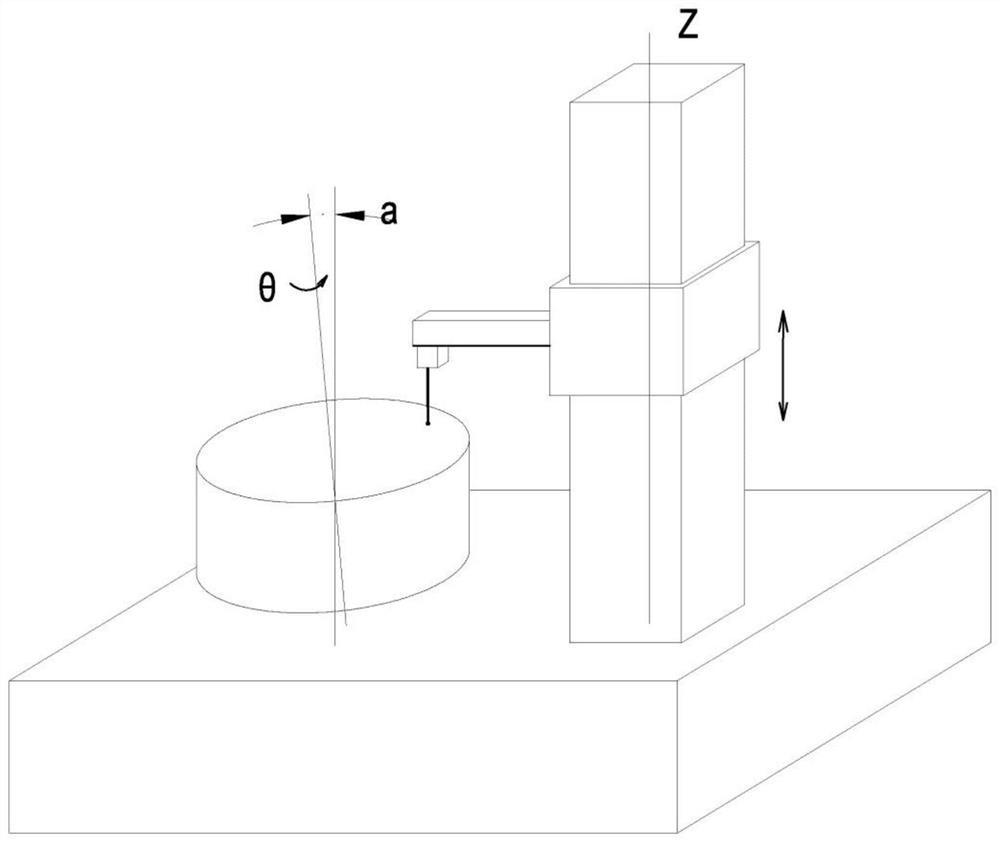

[0031] Based on this calibration system, the following measurement method of the calibration system is carried out to measure the angle between the movement axis of the guide rail 5 and the rotation axis of the turntable 4:

[0032] The reflector 2 is arranged on the turntable 4, the optical transmitting and receiving device 3 is arranged on the guide rail slider 6 through the beam 7, the guide rail slider 6 is installed on the guide rail 5, the guide rail 5 is a Z-axis guide rail, the turntable 4 is rotated, and the light spot A circle is drawn on the mirror 2, and the position of the mirror 2 is adjusted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com