Precision detection device for optical fiber gyroscope production

A fiber optic gyroscope and precision detection technology, applied in the field of fiber optic gyroscopes, can solve the problems of detection data deviation, gyroscope axis deviation, large fixed arc plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

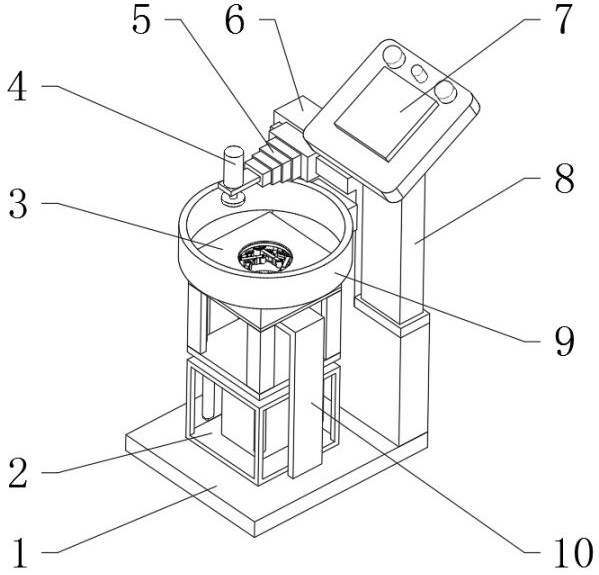

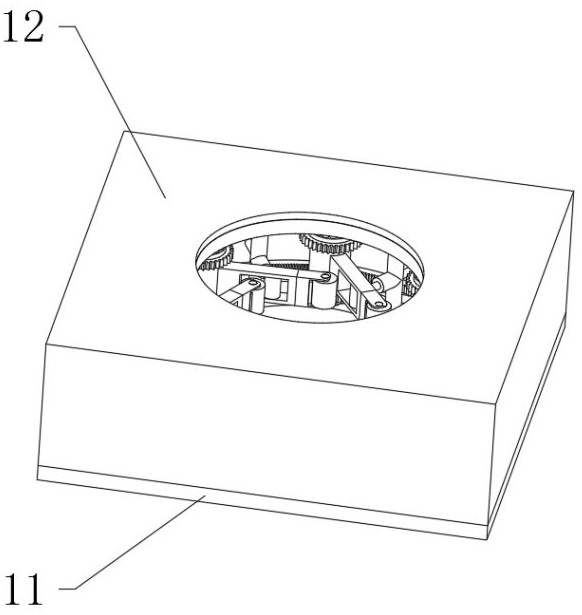

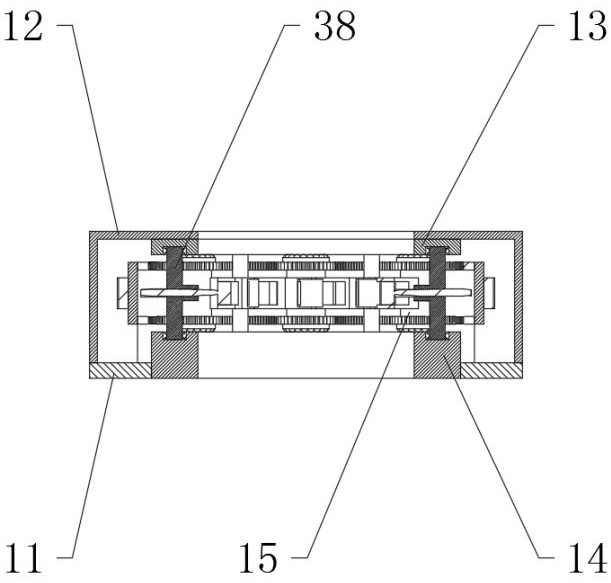

[0035] A fiber optic gyroscope production accuracy detection device, such as Figure 1-8As shown, it includes a bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with an adjustment assembly 2, and the top outer wall of the adjustment assembly 2 is fixedly connected with a locking assembly 3; the locking assembly 3 includes an connecting plate 11 and an end frame 22, and the connecting plate 11 The outer wall of the top is fixedly connected with the cover shell 12, the inner wall of the top of the cover shell 12 is fixedly connected with the upper ring 13, the inner wall of the center of the connecting plate 11 is welded with the lower ring 14, the inner walls of the upper ring 13 and the lower ring 14 are both provided with through grooves, and the upper ring The outer wall of the bottom of 13 and the outer wall of the top of lower ring 14 are fixedly connected with six fixed shafts 16 arranged in circumferential disks. The outer wall of the fixed sh...

Embodiment 2

[0041] A kind of precision detection device for fiber optic gyroscope production, this detection device is the precision detection device described in embodiment 1, such as figure 1 As shown, the top outer wall of the bottom plate 1 is fixedly connected with a bracket 10 and a stand 6, a balance platform is arranged on the outer wall of the top center of the bracket 10, the balance platform is coaxial with the upper ring 13, and a slide rail is arranged on the outer wall of one side of the stand 6 , the outer wall of the slide rail is slidably connected with a mobile frame, the outer wall of one side of the mobile frame is provided with a telescopic box 5, the outer wall of one side of the telescopic box 5 is provided with a screw-in unit 4, the outer wall of the bottom of the screw-in unit 4 is provided with a friction turntable, and the outer wall of the top of the stand 6 A control box 8 is provided, the top outer wall of the control box 8 is provided with an operation panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com