A pipe bending mechanism of a thin-walled short u-bend automatic forming machine

An automatic forming machine and pipe bending technology, which is applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of difficult multi-point clamping, limited clamping and positioning area, poor forming accuracy, etc., to simplify production equipment. The effect of structure, reducing equipment cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below, but the present invention is not limited to the following examples.

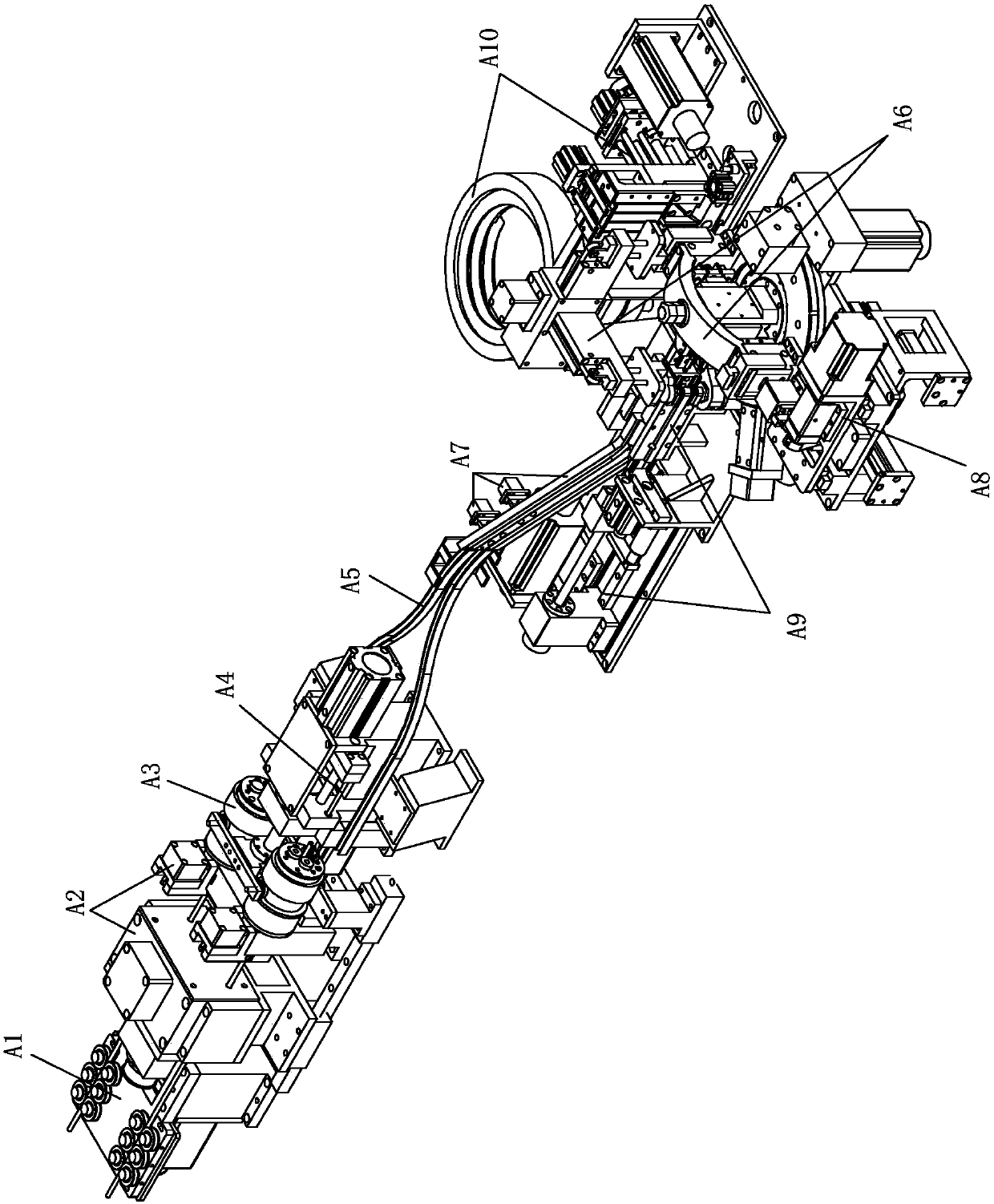

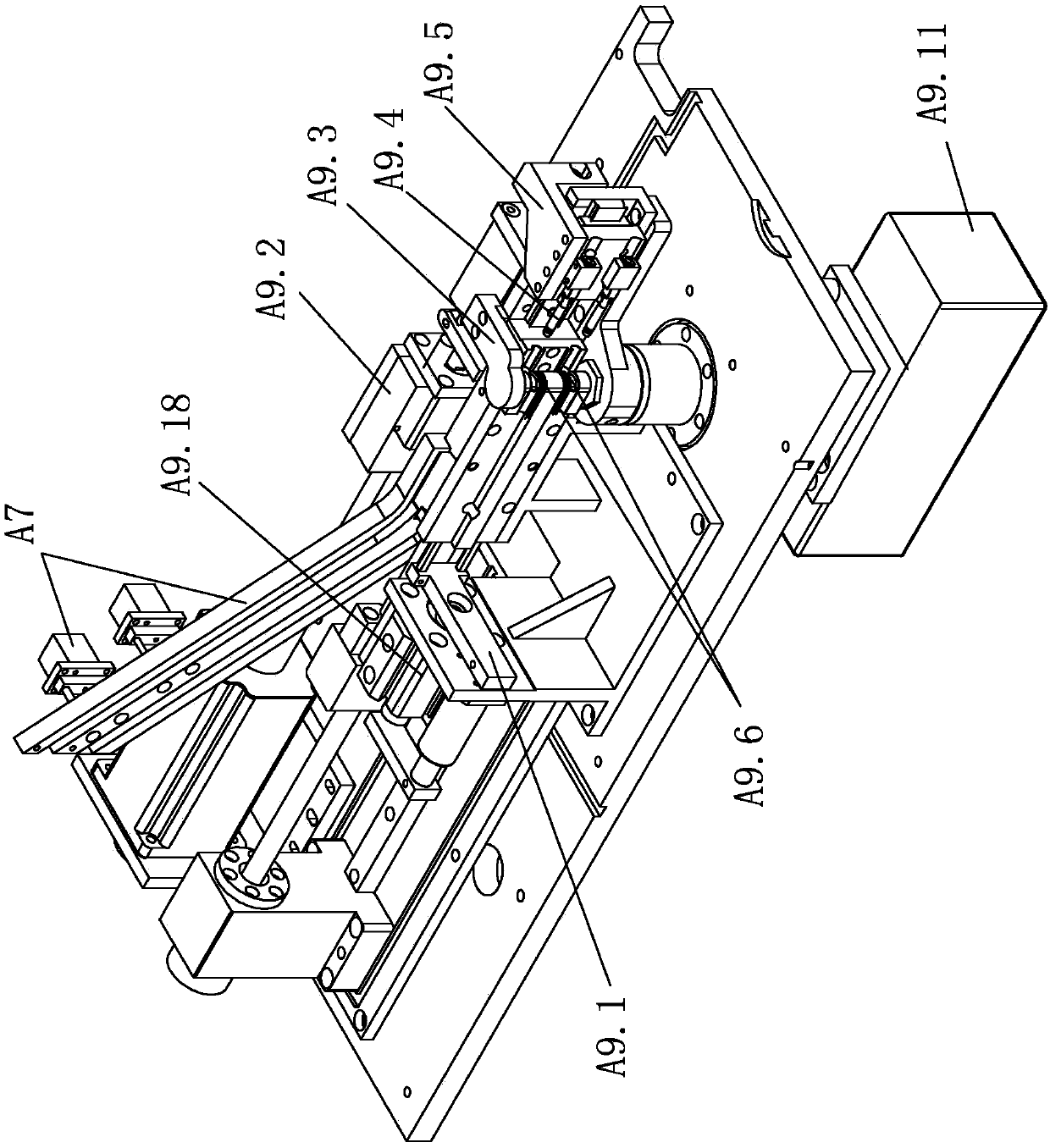

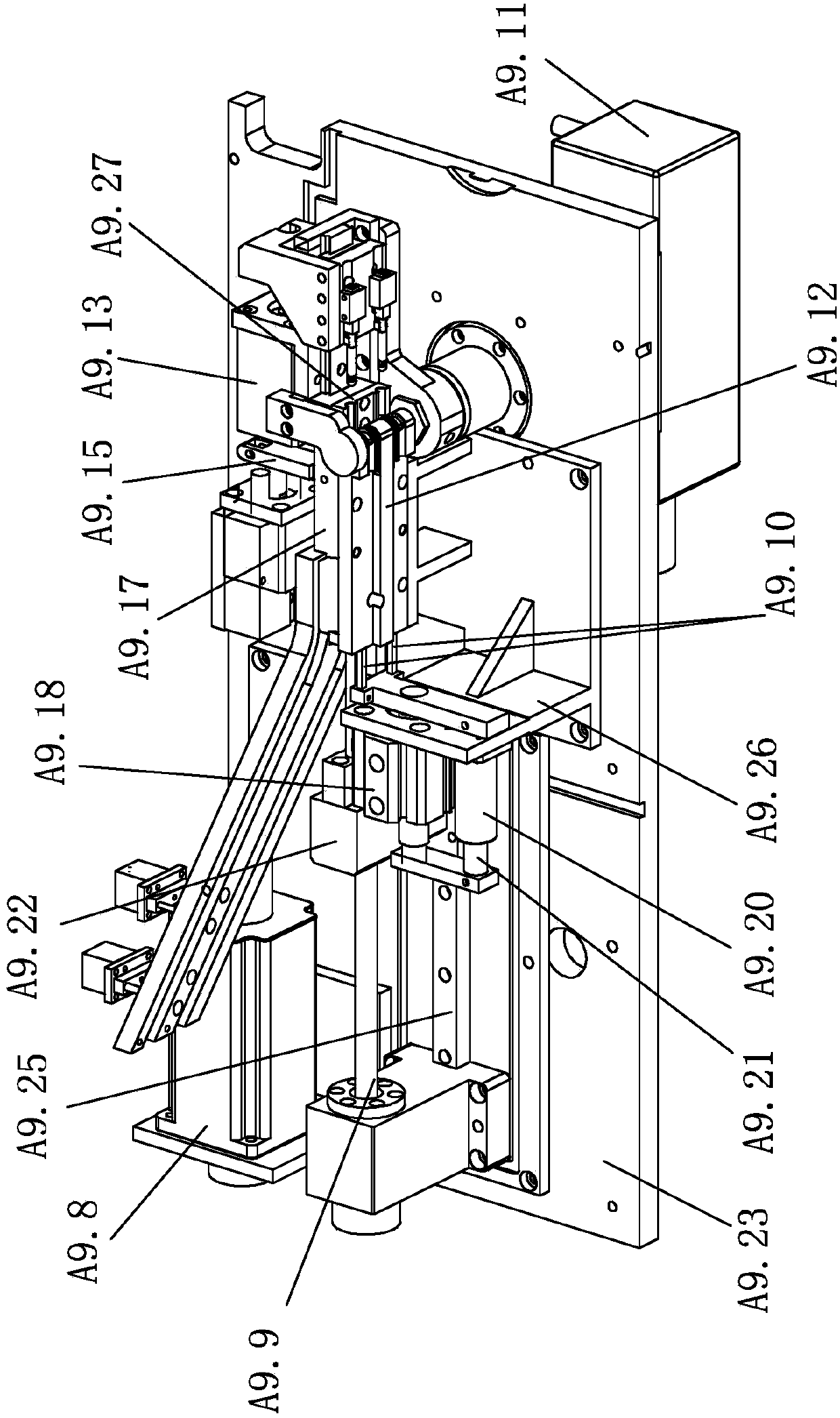

[0035] figure 1 Shown is an automatic thin-wall short U-bend pipe forming machine with welding ring, including: a feeding assembly with a pipe straightening machine A1 and a clamping mechanism A2, through which the pipe is clamped and fed forward; A pipe cutting assembly with a cutter mechanism A3 and a pipe cutting mandrel mechanism A4, through the action of the cutter mechanism and the pipe cutting mandrel mechanism, the pipe is cut into a fixed-length pipe; one has a linear vibrating feeder A5 and an intermittent feeder A7 material transfer assembly sends the fixed-length pipes to the pipe bending mechanism one by one; a pipe bending mechanism A9 bends the fixed-length pipes into a U shape; a circle indexing assembly A6 turns the pipes bent into a U shape To the shaping assembly A8 and the sleeve welding ring A10 assembly.

[0036] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com