A kind of automatic assembly device and assembly method of screws and pins

An automatic assembly device and screw technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of missing screws, large pin pressing errors, and large screw torque errors, so as to reduce labor intensity and ensure reliability. The effect of improving performance and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated and described below in conjunction with specific embodiments. The technical features of the various embodiments of the present invention can be combined correspondingly on the premise that there is no conflict with each other.

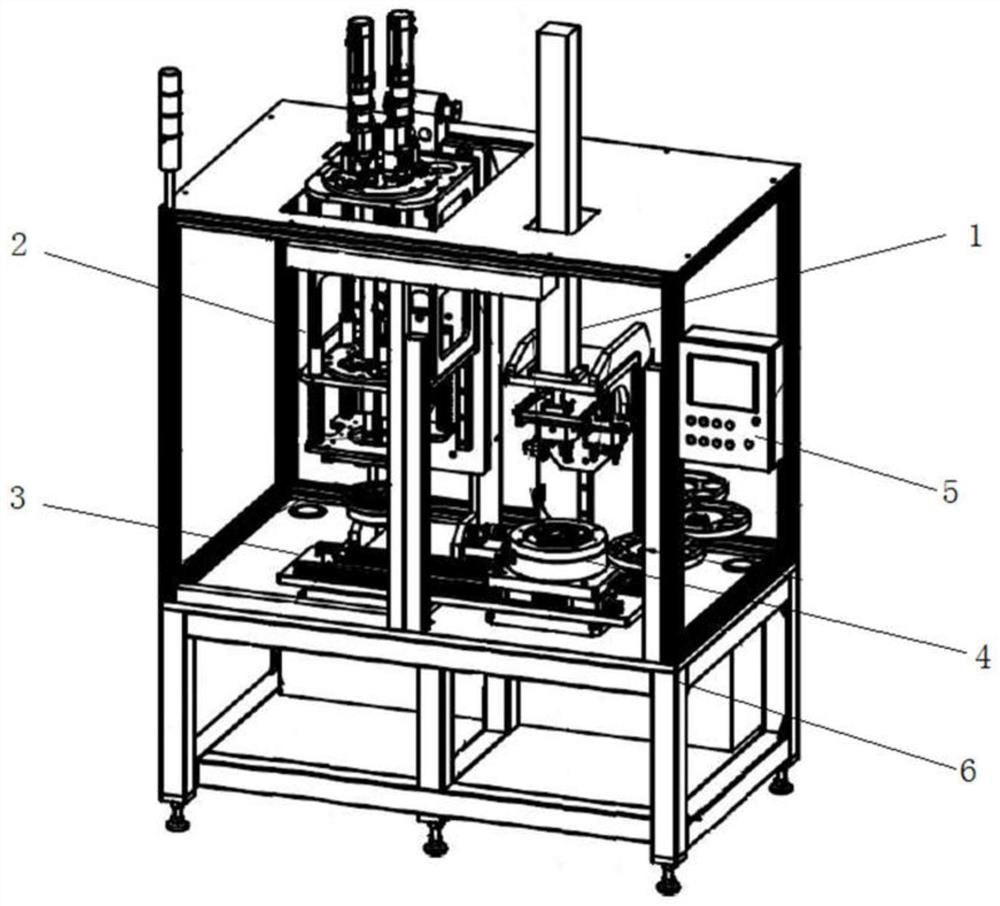

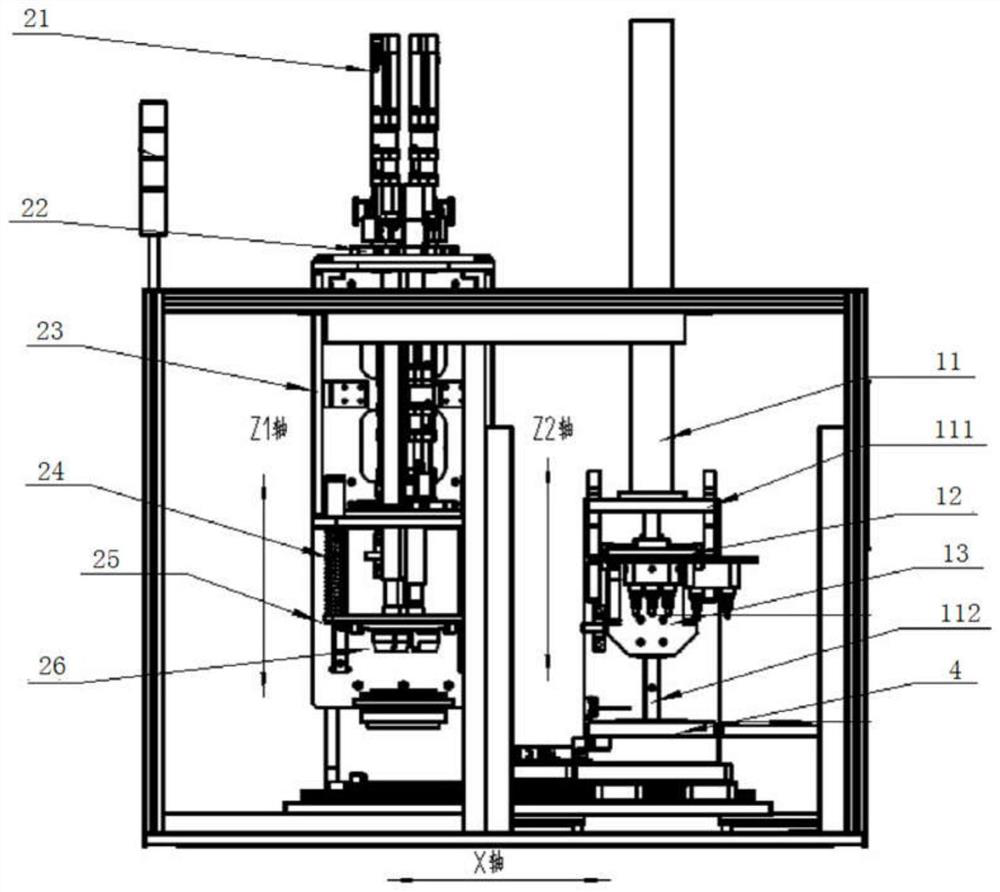

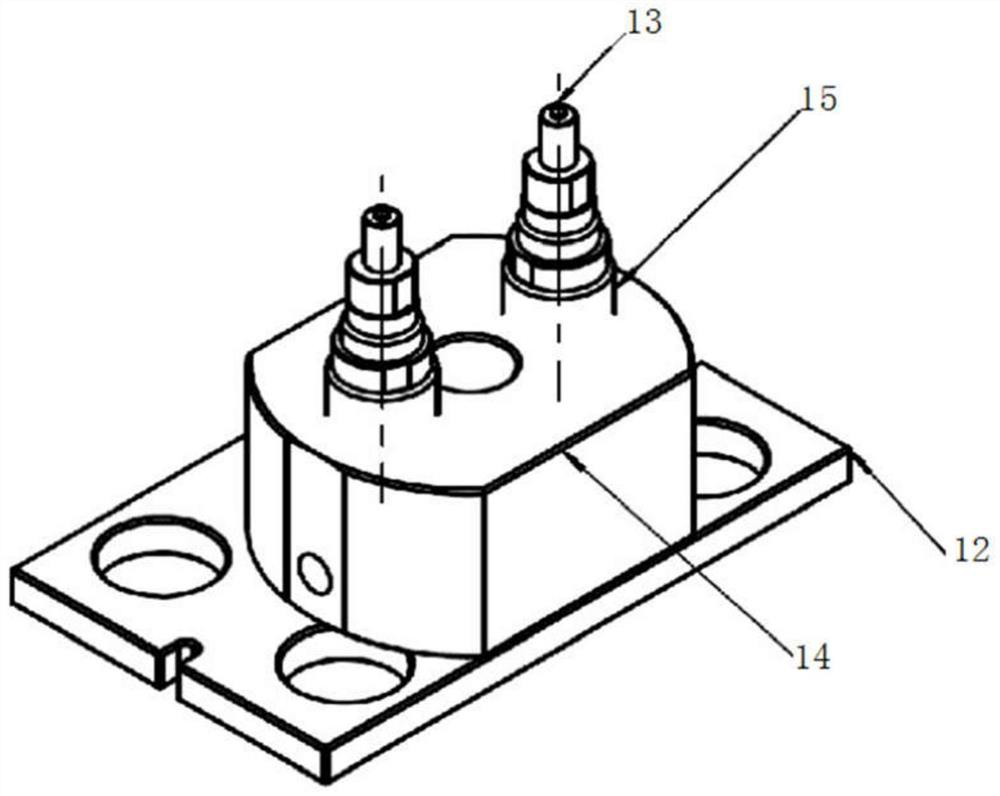

[0037] like figure 1 and 2 As shown, the automatic assembly device for screws and pins provided in this embodiment includes a pin pressing module 1 , a screw tightening module 2 , a slide rail cylinder assembly 3 , a rotatable carrier 4 and a control cabinet 5 .

[0038] In this embodiment, the pin pressing module 1, the screw tightening module 2, the slide rail cylinder assembly 3, the rotatable carrier 4 and the control cabinet 5 can all be installed on one frame 6; the slide rail cylinder assembly 3 Arranged horizontally in the X-axis direction, the rotatable carrier 4 is arranged on the slide rail of the slide rail cylinder assembly, and can move horizontally along the slide rail (X directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com