Aperiodic condition-based maintenance method under condition of considering equipment detection uncertainty

A technology for detecting cycle and uncertainty, applied in forecasting, based on specific mathematical models, instruments, etc., can solve problems such as cost and huge cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The drawings constituting a part of the present invention are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

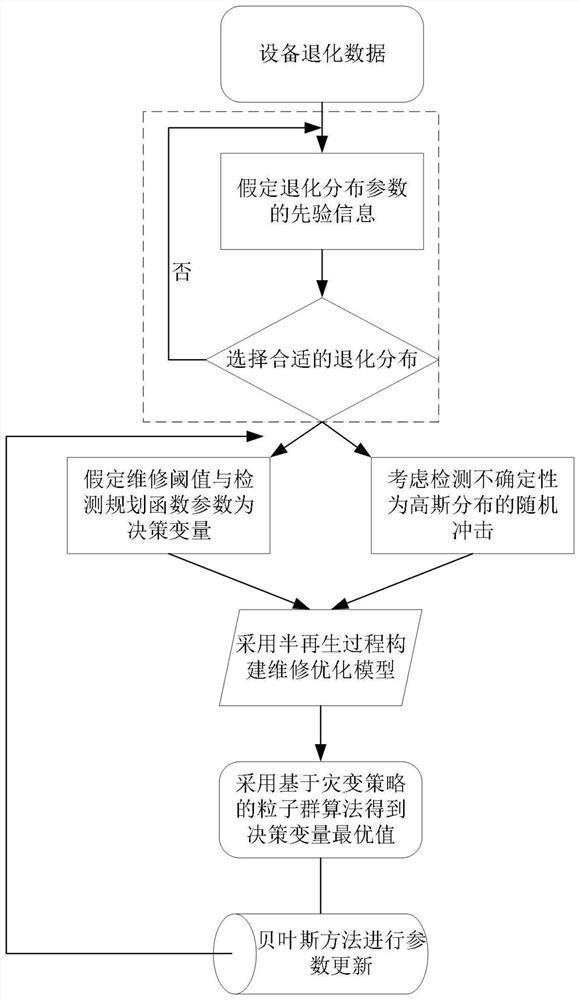

[0061] like figure 1 As shown, this implementation provides a non-periodic condition-based maintenance method considering equipment detection uncertainty, including the following steps:

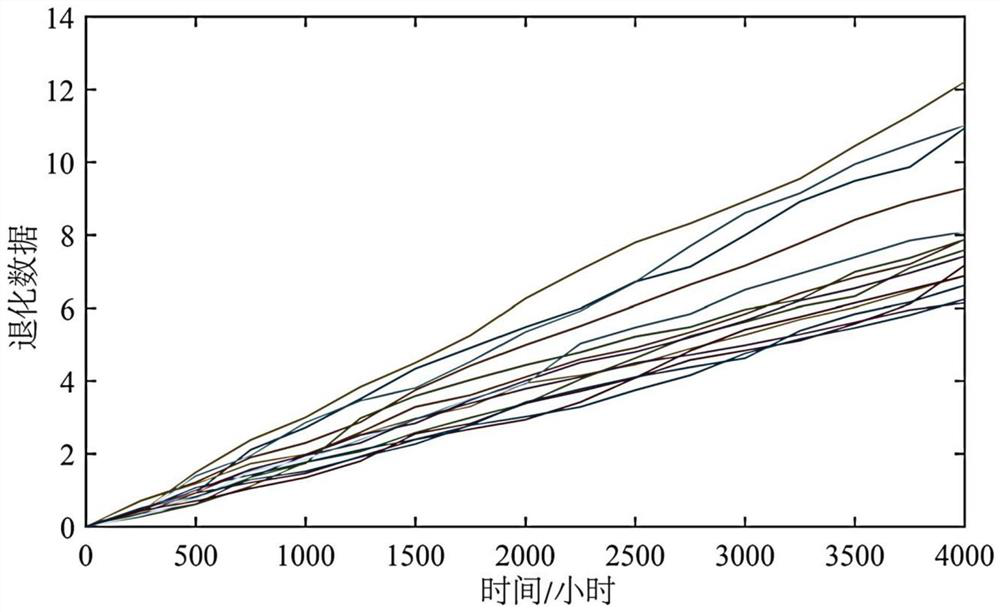

[0062] (1) According to the data of equipment degradation, select the appropriate degradation distribution. Usually, the Wiener process can be used to fit degenerated data for data that is not strictly monotonic, and the gamma process can be used to fit degenerated data for monotonic data.

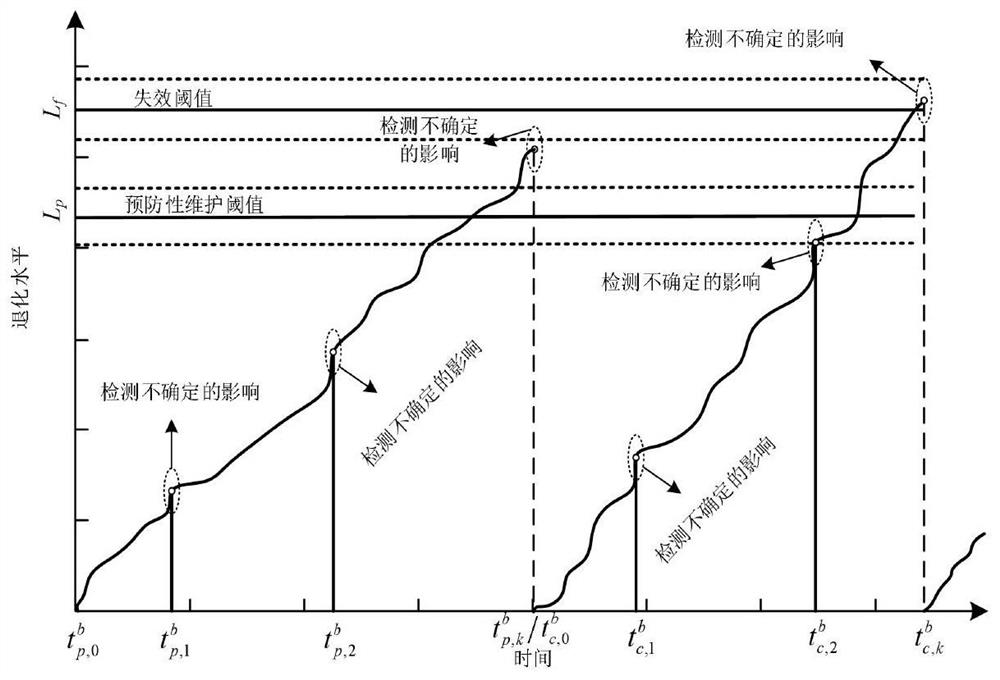

[0063] (2) Select the degradation distribution described in step (1) as the gamma degradation process, and consider its distribution parameters have random effects, and assume the prior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com