Intelligent PID controller online optimization method and system thereof

An optimization method and controller technology, applied in the field of process industry, can solve the problems of weakened PID parameter adjustment, harsh production environment, aggravated working conditions, etc., to achieve the best application prospect and commercial value, strong adaptive ability, and speed up parameter convergence. the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

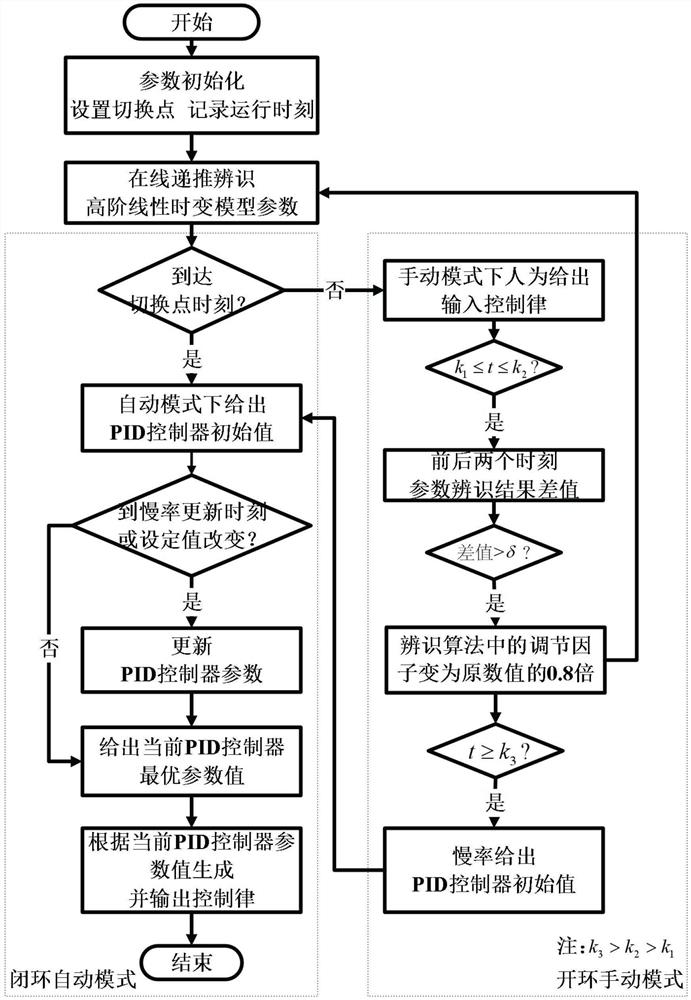

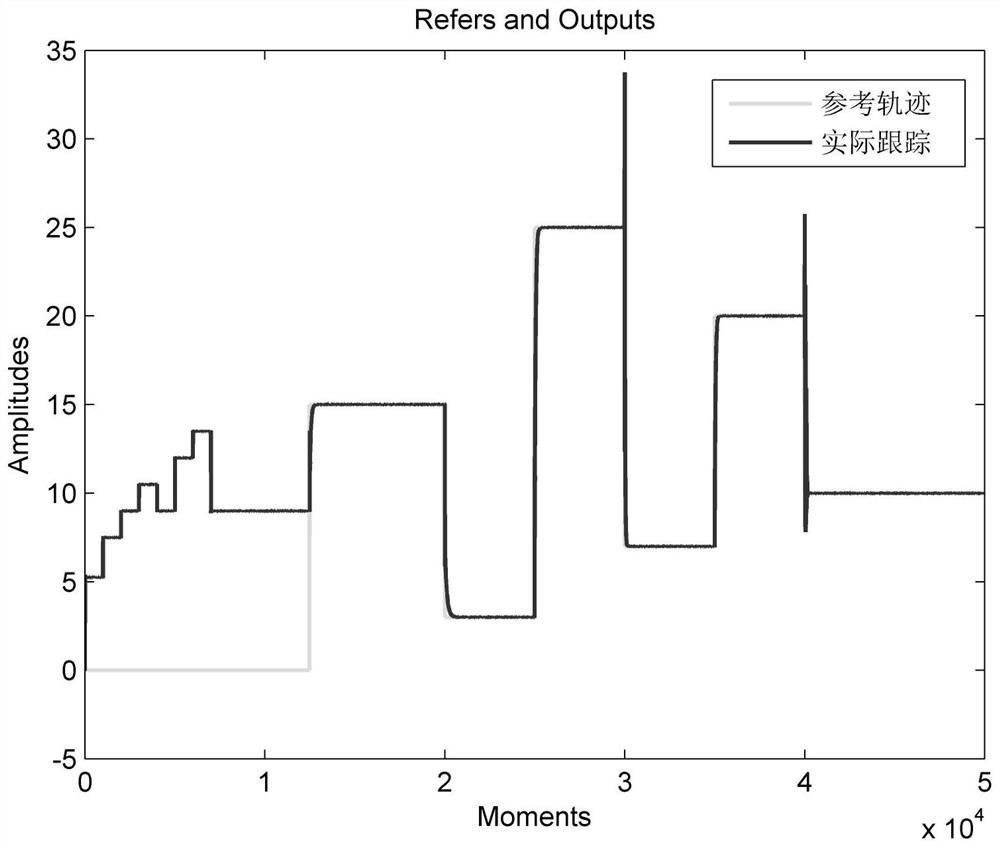

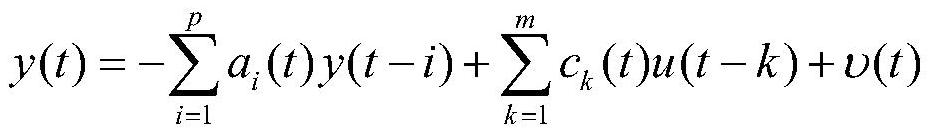

[0039] The intelligent PID controller online optimization method has unique advantages in dealing with changes in process conditions or changes in the system's working state (these changes include slow time-varying, switching modes, nonlinear dynamics, etc.), although such situations mean that the dynamic process Or the internal characteristics of the system (typically such as gain and time constant) have changed, but by establishing a high-order linear dynamic model and building a reliable recursive identification algorithm, we can track this change well. In addition, based on the currently identified model parameters and using the improved swarm intelligence search...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com