Safety production index abnormity rapid sensing method based on Internet of Things and artificial intelligence

A technology of artificial intelligence and safety production, applied in the direction of reasoning method, neural learning method, biological neural network model, etc., can solve the problem that the production process maintenance cannot be carried out in time, and the abnormal production method and actual source cannot be perceived, which is time-consuming and labor-intensive. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

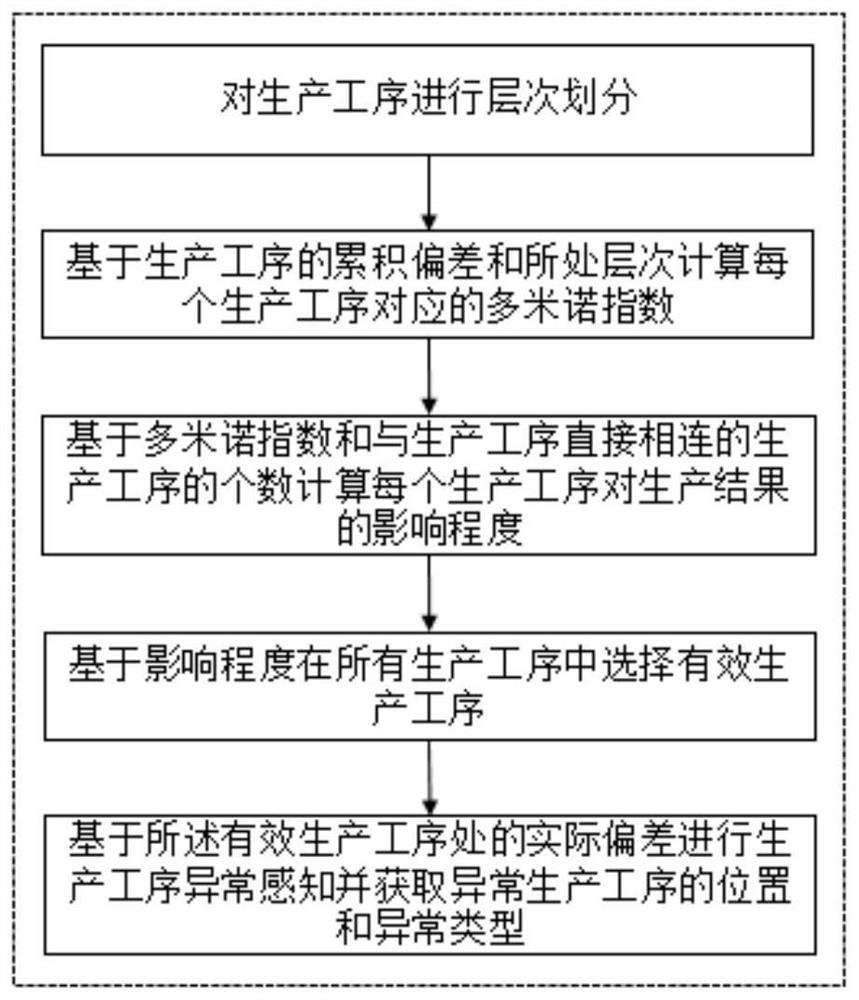

[0030] This embodiment provides a method for fast perception of abnormal safety production indicators based on the Internet of Things and artificial intelligence. The implementation process of the method is as follows: figure 1 As shown, specifically, the method includes:

[0031] Step 1: Divide the production process into levels based on the production process, and each level includes several production processes; this step needs to combine the production process of the enterprise to divide the production processes belonging to the same level in the production process into one level, and create a hierarchy for each level. Each production process is assigned a corresponding ID, and the implementer can also divide the level according to other division basis.

[0032] Step two:

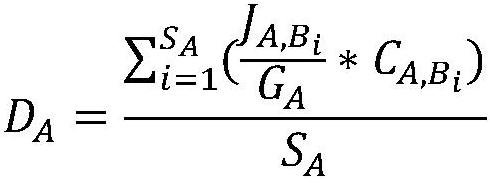

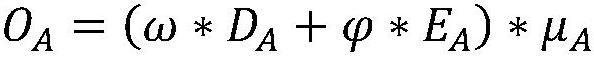

[0033] 1) Calculate the domino index of each production process based on the cumulative deviation of the production process. Specifically, the calculation method of the domino index of each production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com