Film and television high-speed camera equipment

A high-speed camera and film and television technology, which is applied to mechanical equipment, televisions, supporting machines, etc., to achieve the effect of convenient debris handling and stable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

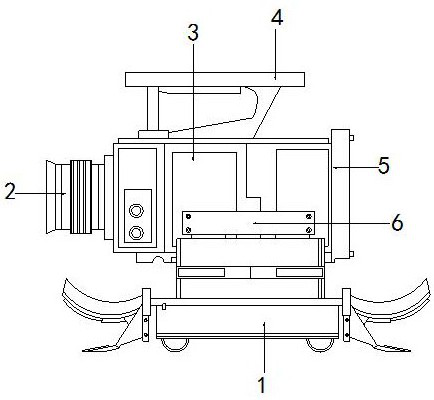

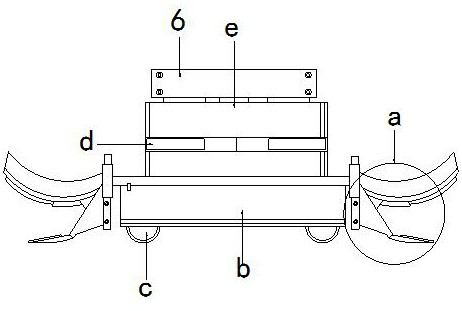

[0026] see Figure 1-Figure 3 , the present invention provides a technical solution for high-speed video camera equipment: its structure includes: a rail frame device 1, a lens module 2, a main body 3, a holding frame 4, an interface end plate 5, and a connecting horizontal plate 6. The frame 4 is installed on the top of the main body 3 and locked with the main body 3, the front end of the main body 3 is provided with a lens module 2, the lens module 2 is screwed with the main body 3, and the rear side of the main body 3 is provided with a There is an interface end plate 5, the interface end plate 5 is locked with the main body 3, the side of the main body 3 is provided with a connecting horizontal plate 6 and is locked with the connecting horizontal plate 6, and the bottom of the connecting horizontal plate 6 is provided with Track frame device 1, said track frame device 1 is buckled with connecting horizontal plate 6, said track frame device 1 includes scraper body a, fixed ...

no. 2 example

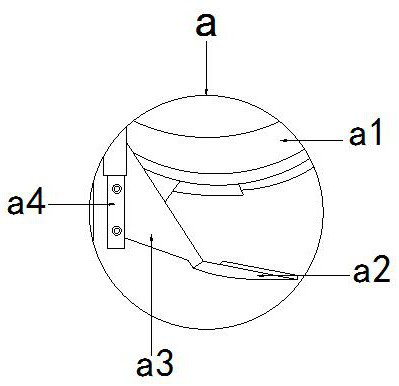

[0030] see Figure 4-Figure 6 , the present invention provides a technical solution for high-speed video camera equipment: its structure includes: the adsorption plate device a1 includes an adsorption groove device a11, an adjustment bar a12, a docking buckle plate a13, and an arc plate a14, and the adsorption groove device a11 is installed on The bottom of the arc plate a14 is buckled with the arc plate a14, the side of the arc plate a14 is provided with a docking plate a13, the inner side of the adsorption tank device a11 is provided with an adjustment bar a12, and the adjustment bar a12 is connected with the adsorption tank device a11 buckle.

[0031] The suction groove device a11 includes a fixed frame a111, a magnetic strip a112, and a spliced suction piece a113. The spliced suction piece a113 is installed on the side of the magnetic strip a112 and fastened with the magnetic strip a112. Box a111.

[0032] The contact plate device a2 includes a sliding section a21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com