Mining roadway grooving machine

A slotting machine and roadway technology, applied in the direction of slitting machinery, propulsion, driving devices, etc., to achieve the effect of ensuring project quality, reducing link costs and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

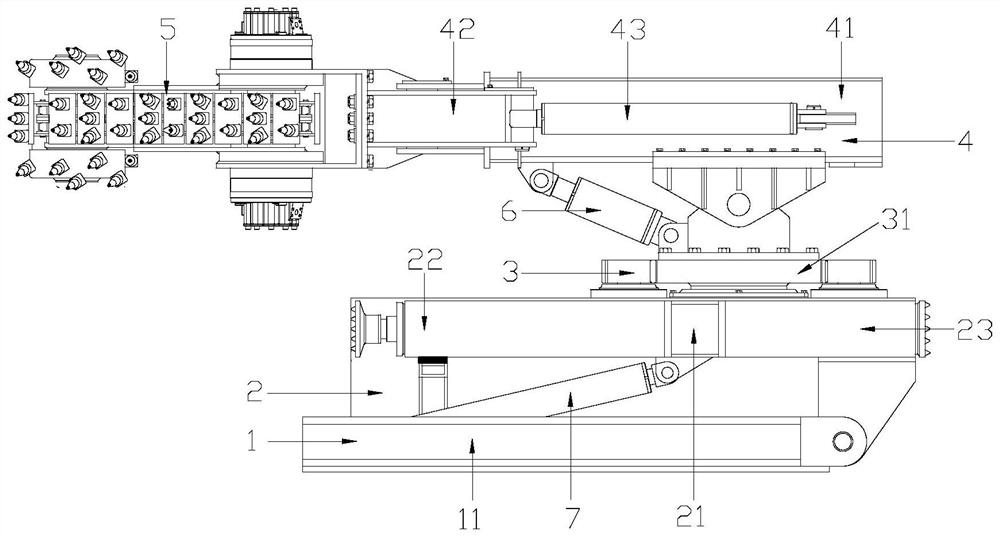

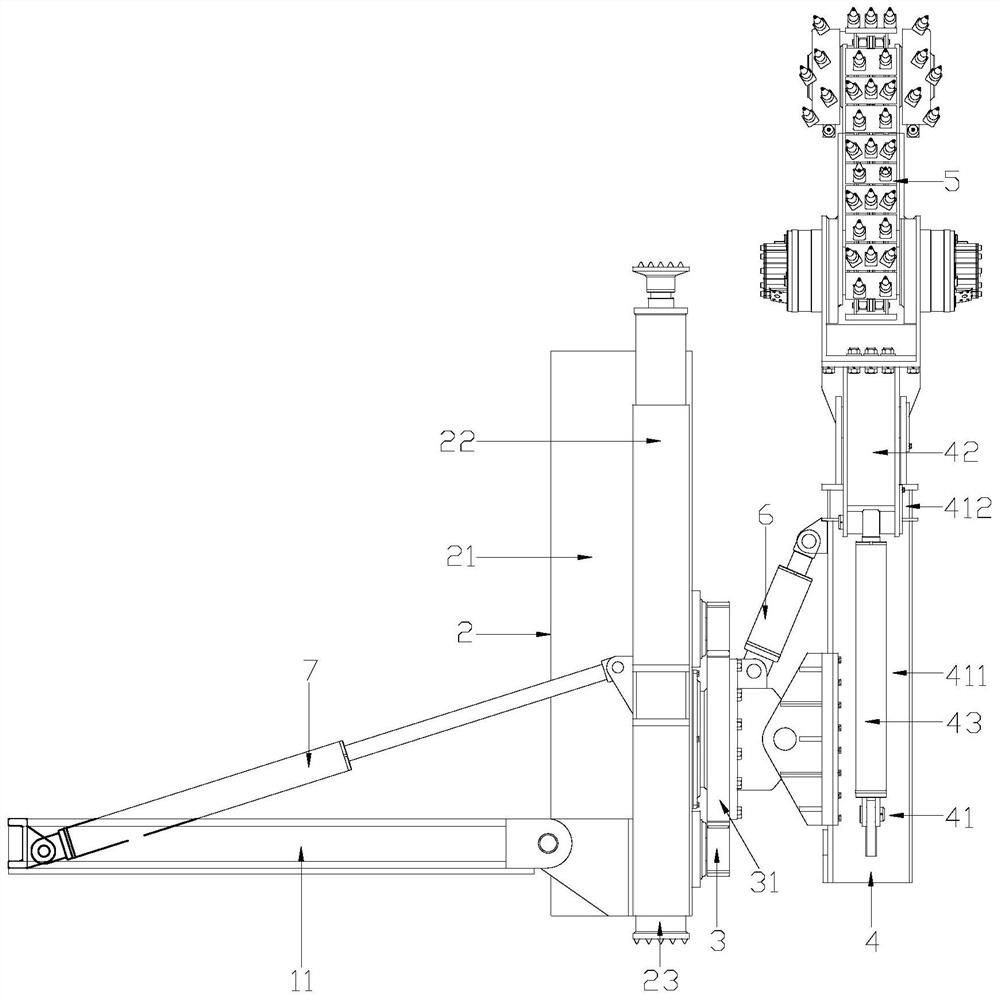

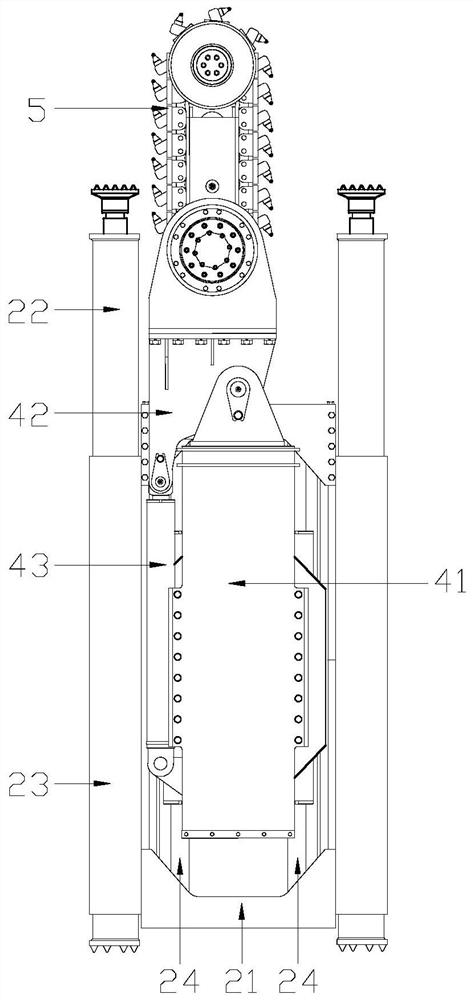

[0019] Example: such as Figure 1 to Figure 4 As shown, the mining roadway slotting machine includes a fixed base 1, an overturned base 2, a rotary drive 3, a cantilever 4, and a milling head 5; the overall fixed base 1 includes two parallel fixed beams 11, A connecting beam 12 is fixed between one end of the two fixed beams 11; the flip base 2 includes a mouth-shaped flip frame 21, and a top hydraulic cylinder 22 and a leg hydraulic cylinder 23 are respectively fixed on both sides of the flip frame 21. Be provided with two double-rod hydraulic cylinders 24 shown in parallel with the fixed beam 11 in the flip frame 21, the piston rod of the double-rod hydraulic cylinder 24 is fixedly connected with the flip frame 21; the bottom surface of the flip frame 21 is hinged with the fixed beam 11; An overturning hydraulic cylinder 7 is arranged between the overturning frame 21 and the fixed base 1, the cylinder barrel of the overturning hydraulic cylinder 7 is hinged with the fixed ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com