Layered and partitioned adjusting type ammonia spraying denitration device and denitration method thereof

A layered and zoning, adjustable technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as unadjustable ammonia concentration and uneven NOx concentration, and achieve adjustability and NOx distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

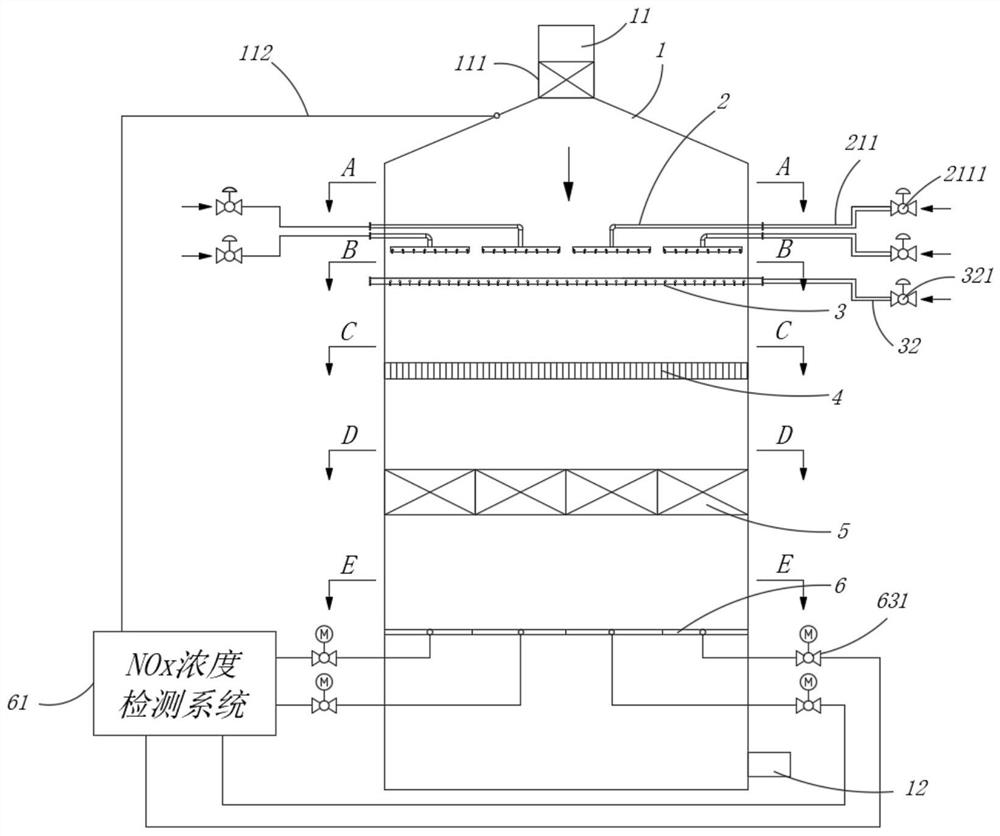

[0032] see figure 1 , this embodiment provides a layered and partitioned adjustable ammonia injection denitrification device, including a reaction tower 1, and the reaction tower 1 is provided with a flue gas inlet 11 and a flue gas outlet 12. The first ammonia injection grid 2 , the second ammonia injection grid 3 , the rectification grid 4 , the catalyst layer 5 , and the smoke detection system 6 are sequentially arranged in the reaction tower 1 along the flow direction of the flue gas indicated by the arrow.

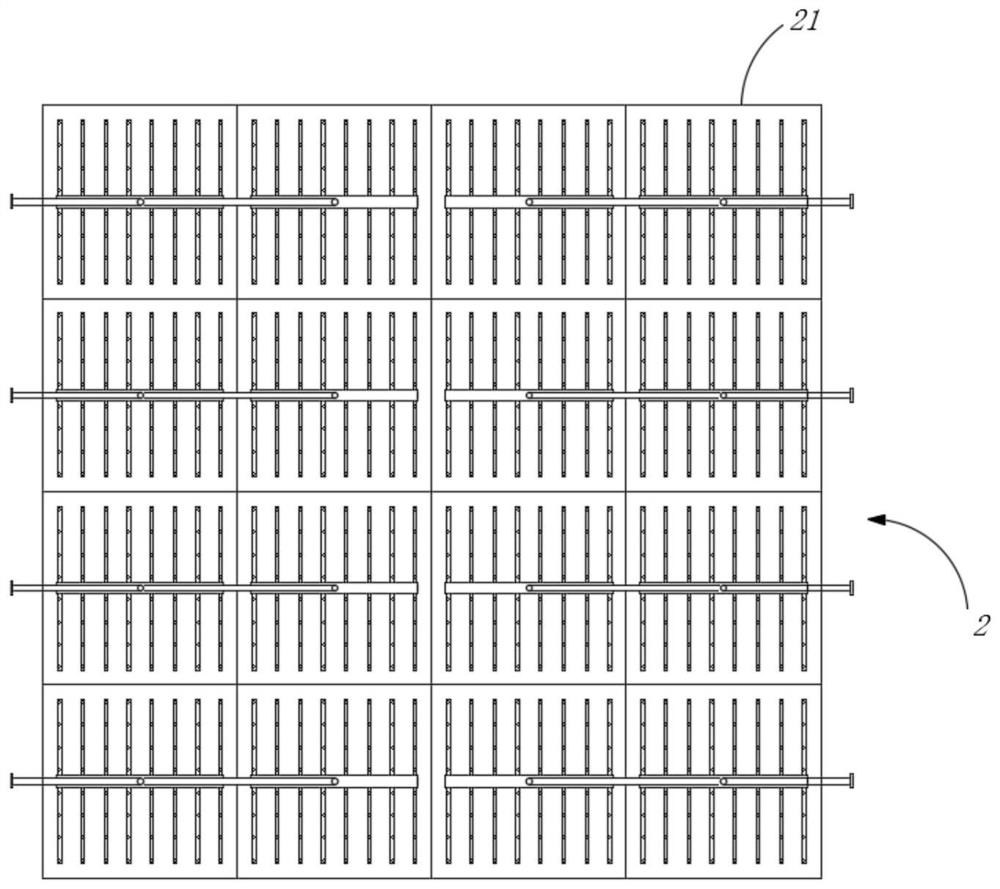

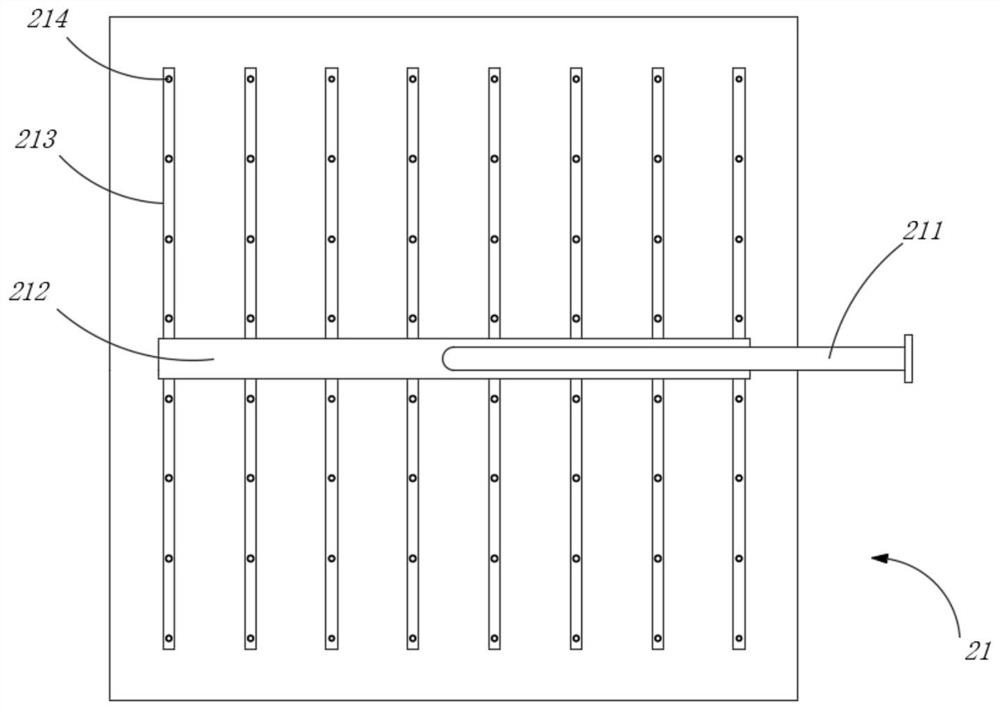

[0033] Please combine figure 2 , the first ammonia injection grill 2 is a zone-adjustable ammonia injection grid, which is divided into 16 zones along the direction perpendicular to the flow of flue gas, and each zone is provided with a first sub-grid for independent ammonia injection 21; The number of partitions is not limited, it is adjusted according to the size of the reaction tower 1 . Please refer to image 3 , the first sub-grid 21 includes a first inlet pi...

Embodiment 2

[0039] In combination with the denitrification device in Embodiment 1, this embodiment also provides a denitrification method for a layered and partitioned adjustable ammonia injection denitrification device, which includes the following steps:

[0040] S1, the flue gas is introduced from the flue gas inlet, and at the same time the first ammonia injection grid and the second ammonia injection grid start to work, injecting ammonia gas into the reaction tower;

[0041] S2, the flue gas passes through the first ammonia injection grid, the second ammonia injection grid, the rectification grid and the catalyst layer to the flue gas detection system in sequence;

[0042] S3, the subsystems of the flue gas detection system respectively extract the flue gas in the reaction tower to detect the NOx concentration;

[0043] S4, when the flue gas flow rate and the NOx concentration in the flue gas change, only the second ammonia injection grill can be adjusted, and only when the NOx concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com