Plate sanding device for furniture production

A sanding and plate technology, applied in the direction of grinding/polishing safety devices, grinding drive devices, manufacturing tools, etc., can solve the problems of poor air quality, wood chips are easy to float into the air, etc., and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

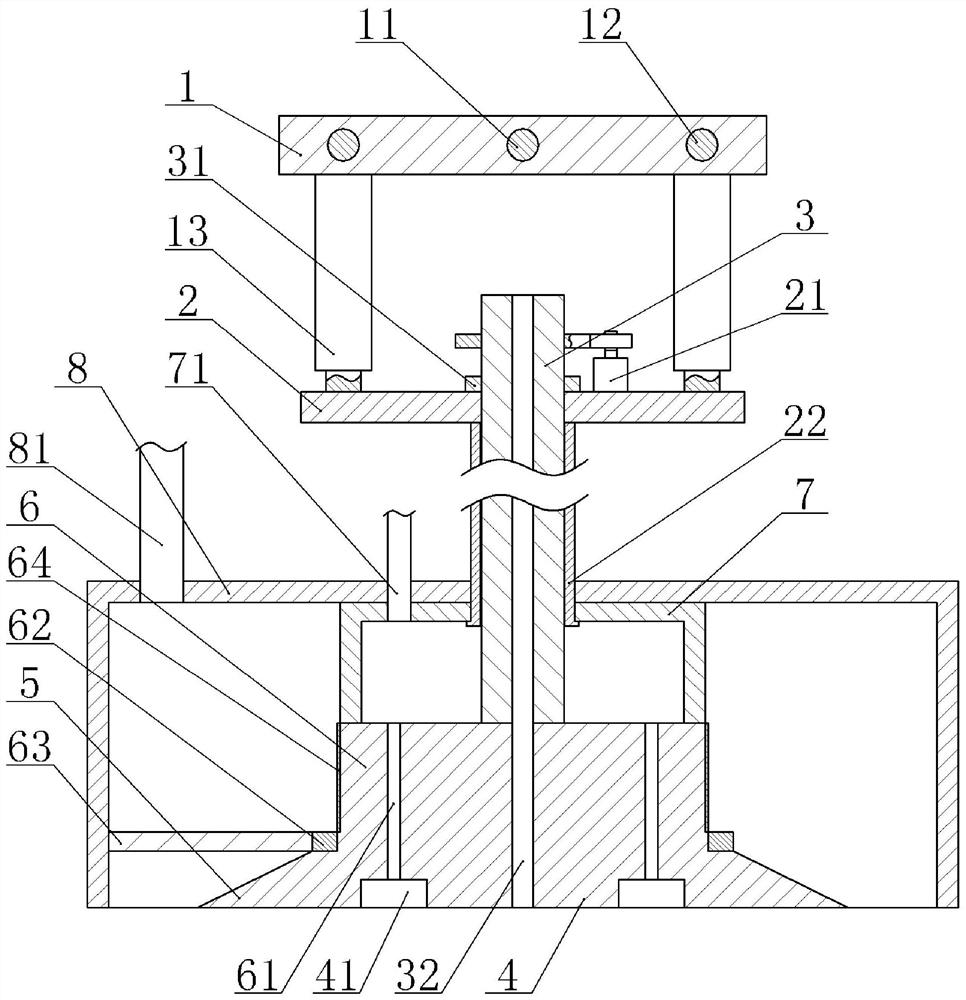

[0023] Panel sanding devices for furniture production, e.g. figure 1 As shown, it includes a frame, a grinding unit, a dust removal unit and a moving unit. The moving unit includes a lateral moving part, a fixed plate 2, a mounting base 1 and two vertical moving parts 13. The lateral moving part includes a screw 11 and a forward and reverse motor. And two guide rods 12, the screw rod 11 and the guide rod 12 all run through the mounting seat 1 along the transverse direction, and the two ends of the guide rod 12 are respectively fixed on the frame by bolts, the two ends of the screw rod 11 all pass through the frame, and the screw rod 11 and the Bearings are arranged between the frames, and the structure and installation method of the bearings in this embodiment are the same as those of the prior art, so that the screw rod 11 can rotate relative to the frame. In this embodiment, the screw rod 11 is threadedly matched with the mounting base 1. Specifically, the screw rod 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com