Fraxinus mandshurica bending processing and cooking device

A technology of bending processing and cooking equipment, which is applied in the direction of wood bending, wood processing equipment, wood heating, etc., can solve the problems of wood breakage, manual adjustment of the bending angle of ash wood, etc., and achieve good fixing effect and good adjustment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

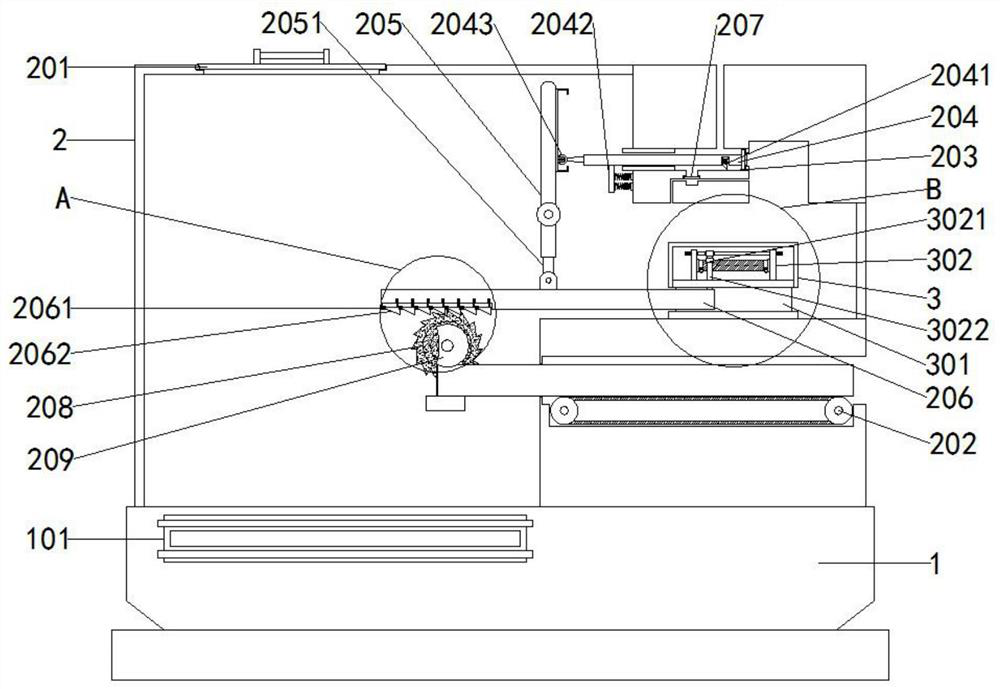

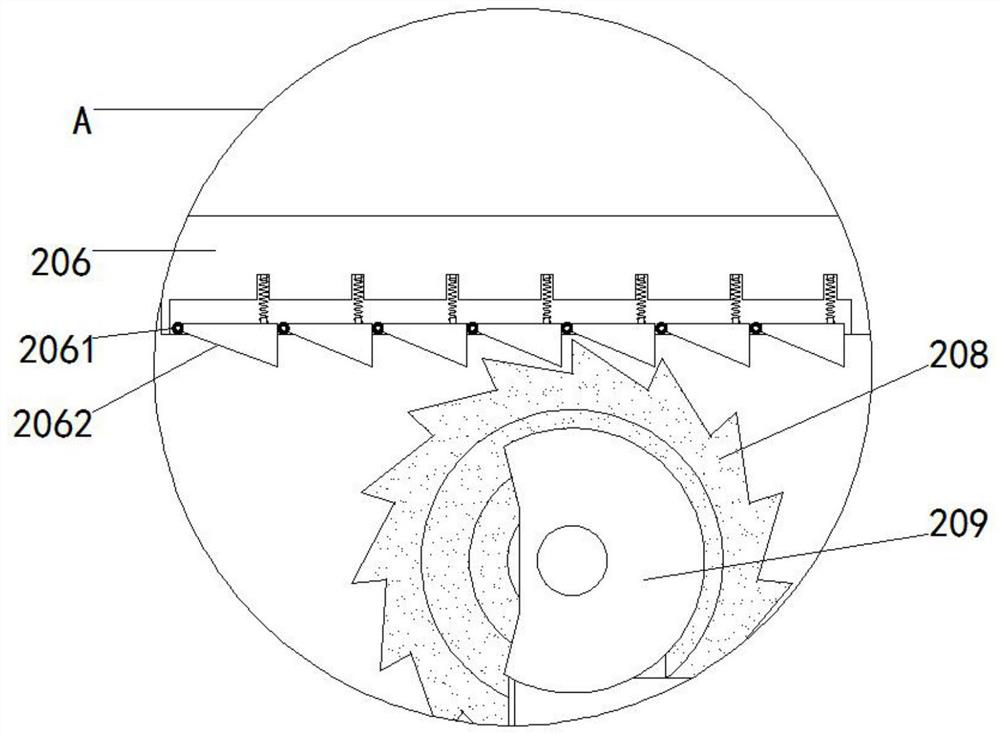

[0027] as attached figure 1 to attach Figure 5 Shown: a mandshurica wood bending processing cooking device, including a base 1, a heater 101, a shell 2, a sealing cover 201, a roller A202 and a piston sleeve 203, a heater 101 is embedded in one end of the base 1, the base The top of 1 is fixed with the shell 2, the top end of the shell 2 is hingedly provided with a sealing cover 201, the outer end of the shell 2 is rotatably provided with a roller A202, and there are two rollers A202, and the outer drive of the two rollers A202 is provided with a belt, A piston sleeve 203 is fixedly mounted on the inner top of the housing one 2, and a ventilation groove is provided through the top of the piston sleeve 203 and the top of the housing one 2 . A pressure relief mechanism is arranged in the piston sleeve 203, and a wood bending mechanism is arranged in the casing one 2 .

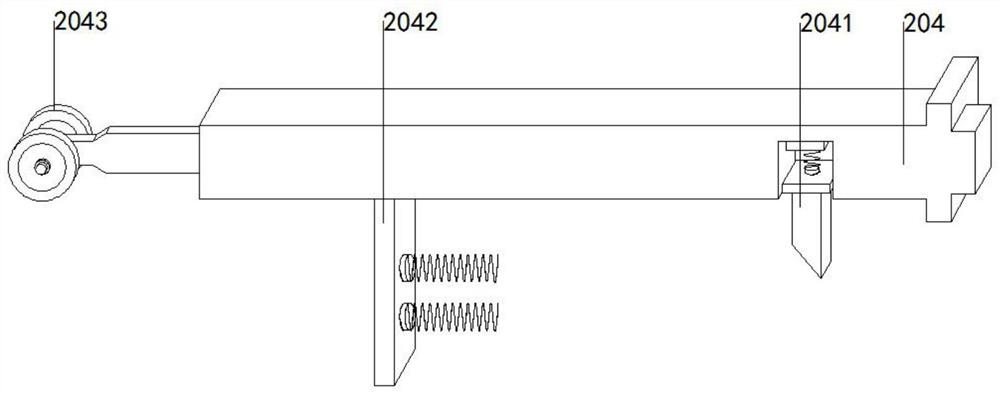

[0028] Wherein, the pressure relief mechanism is composed of a piston 204, a block 2041 and a memory alloy ...

Embodiment 2

[0034] The present invention also includes a rheostat heating structure, which is composed of a casing 2 3, a piston sleeve B301, a rheostat 302, a sliding plate 3021, a fixed rod 3022 and a heater 101;

[0035] The inner side of the first shell 2 is fixedly installed with the second shell 3 close to the bottom of the piston sleeve 203, the bottom of the second shell 3 is embedded with a piston sleeve B301, the top of the piston sleeve B301 is fixedly installed with a rheostat 302, and the top of the rheostat 302 is movable. The other end of the piston B206 is connected to the sliding piece 3021 through the fixed rod 3022. One end of the rheostat 302 is electrically connected to the heater 101 through a wire. Slide the inner side of the piston sleeve B301 at the bottom of the housing 23. At this time, the fixed rod 3022 on the top of the other end of the piston B206 will drive the sliding piece 3021 to slide on the surface of the rheostat 302. Because the larger the cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com