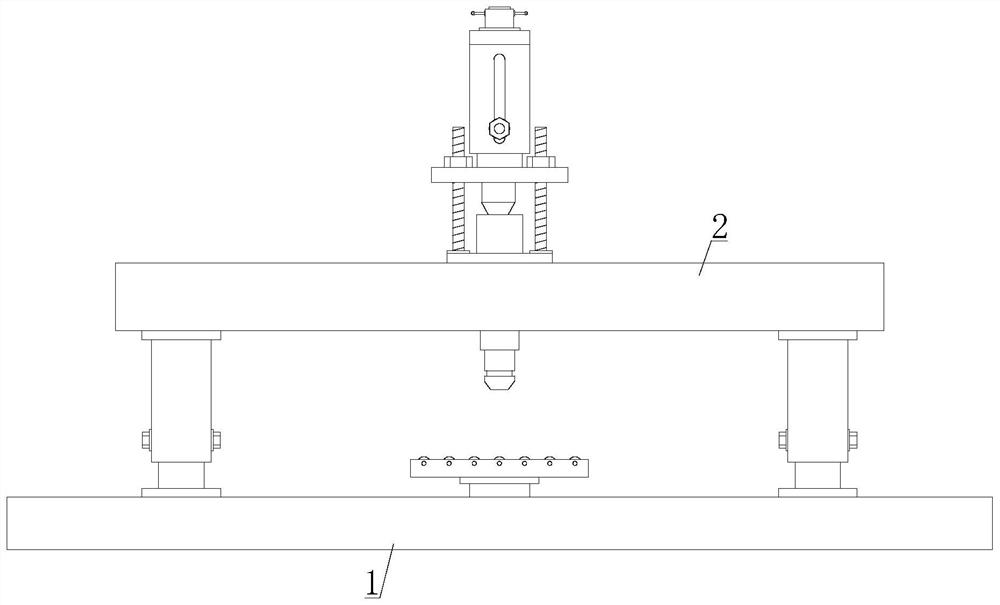

Laser marking device for glass product processing and implementation method thereof

A glass product and laser technology, applied in the direction of copying/marking, typewriter, printing, etc., can solve the problems of glass product scars, scrapped glass products, excessive strength, etc., and achieve the effect of avoiding scars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

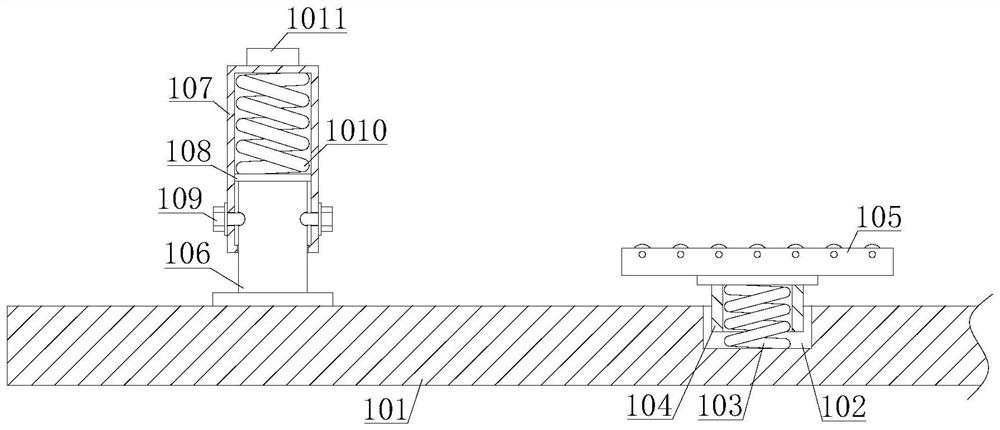

[0034] In order to better demonstrate the implementation process of the laser marking device for glass product processing, this embodiment now proposes a method for implementing a laser marking device for glass product processing, including the following steps:

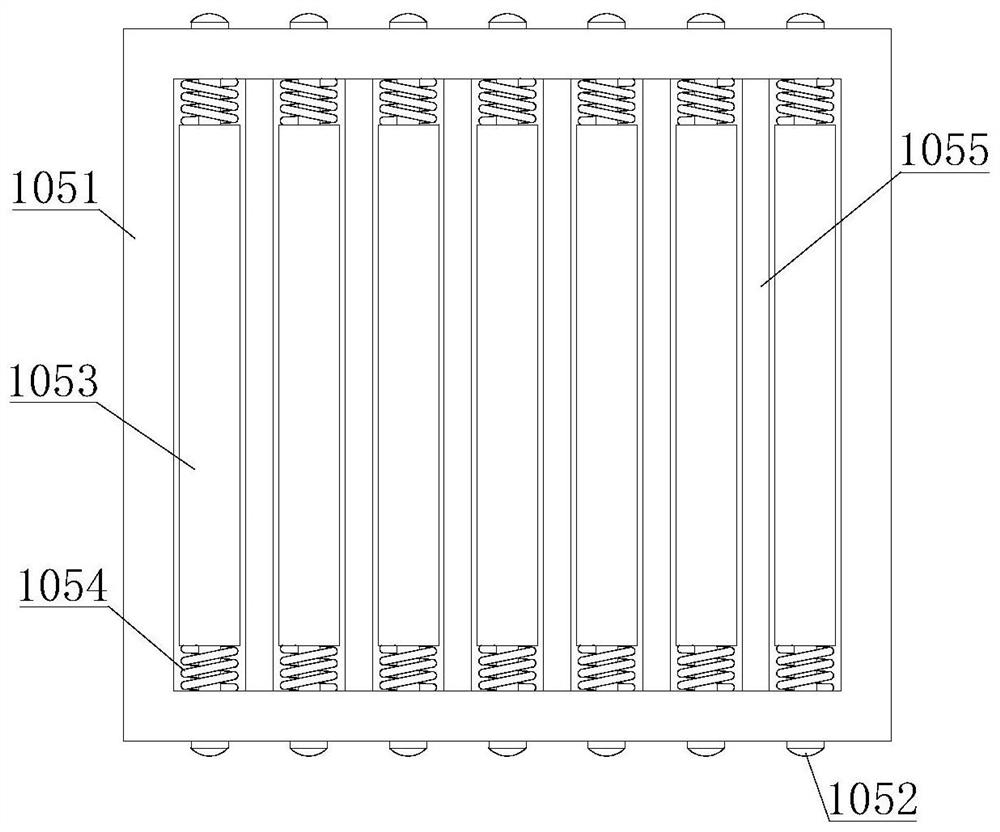

[0035] Step 1: Place the glass product to be processed on the processing support plate 105 of the processing base 1, and adjust the processing part to the lower part of the laser marking component 2;

[0036] Step 2: Adjust the connecting bottom plate 271 to the height position of the adjusting screw 269, and nest the bottom of the laser tube 27 in the through card nest 268;

[0037] Step 3: adjust the slider bolt 275 in the laser light sleeve 27, so that the laser generator 279 and the laser emitting head 2711 below are adjusted downward;

[0038] Step 4: Turn on the laser generator 279 to emit laser light from the laser emitting head 2711 and irradiate the surface of the glass product after being reinforced by the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap