Life line for workshop high-altitude operation and installation method

A high-altitude operation and lifeline technology, applied in safety belts, life-saving equipment, construction, etc., can solve the problems that affect the construction of non-high-altitude areas, and it is difficult to ensure the stability of the wire rope, so as to achieve the effect of easy tensioning and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

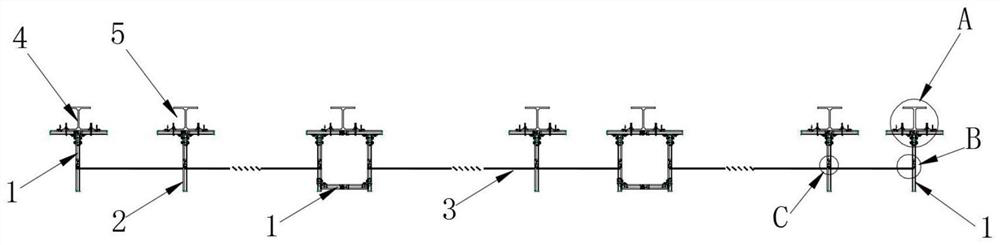

[0039] Such as figure 1 As shown, this embodiment provides a lifeline for high-altitude operations in workshops, including

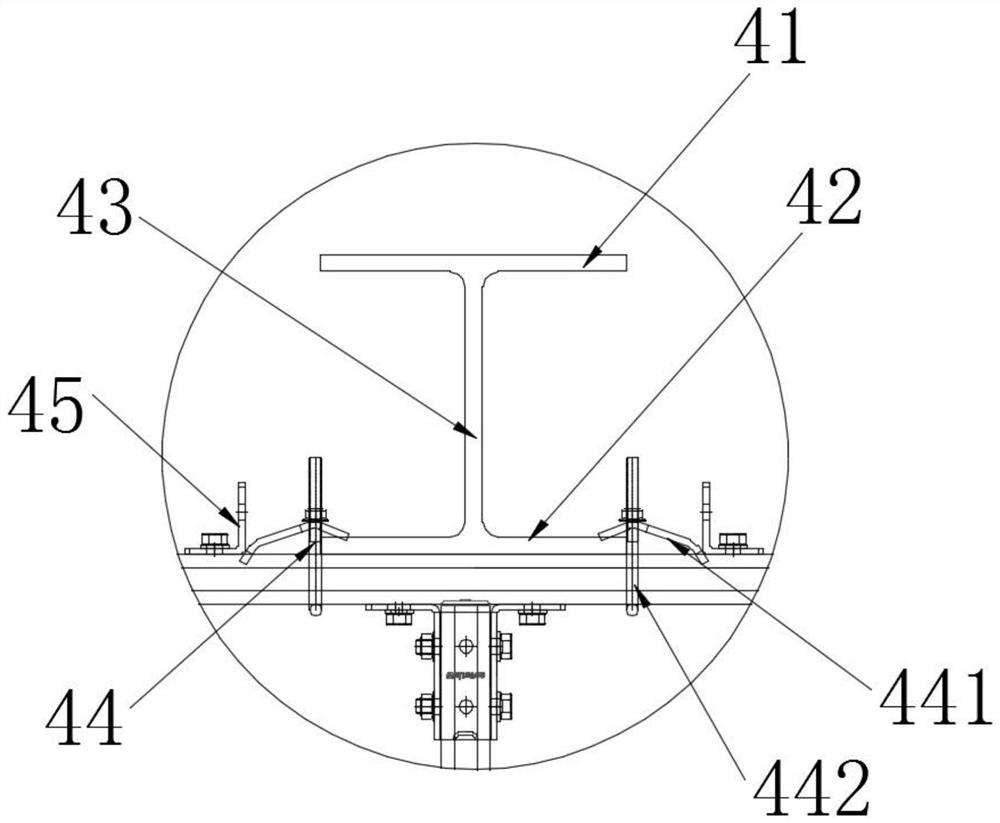

[0040] Four fixed brackets 1 are connected to the steel structure on the top of the workshop through the first hoisting structure 4;

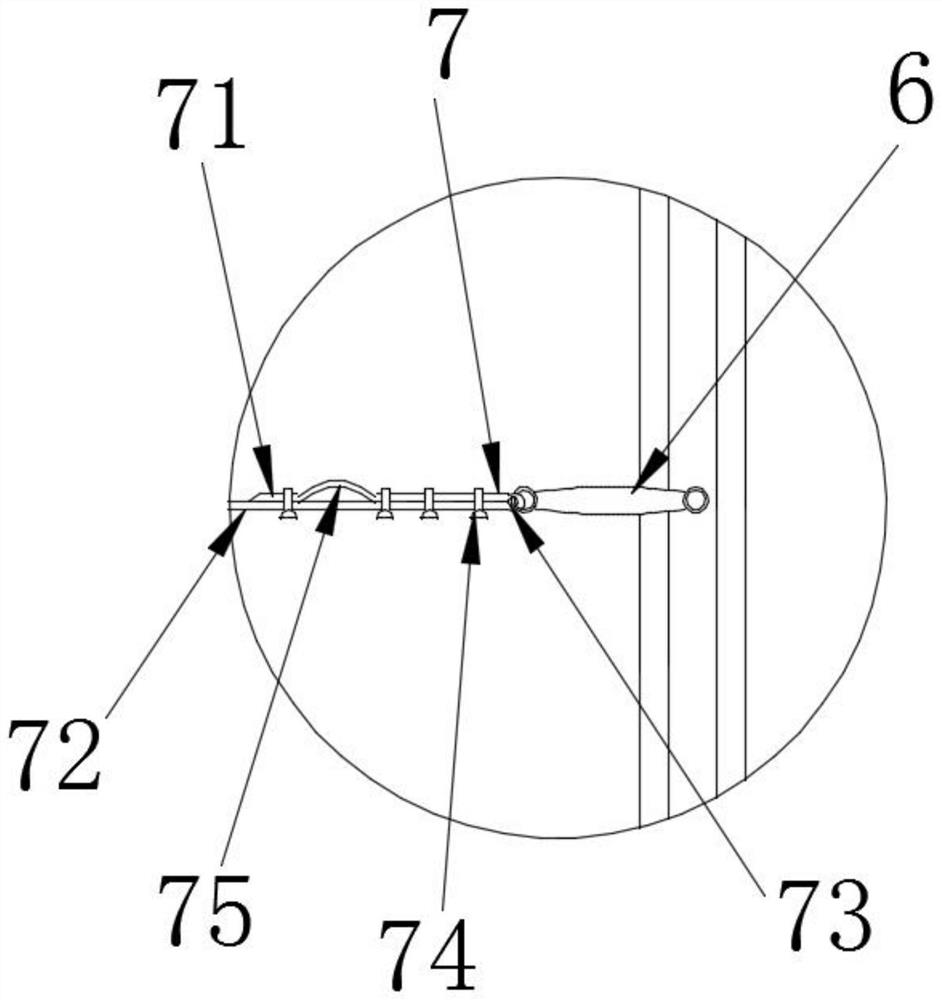

[0041] A plurality of support hangers 2, a plurality of support hangers 2 are arranged between every two fixed supports 1, and are connected to the steel structure at the top of the workshop through the second hoisting structure 5;

[0042] The wire rope 3 is connected to the fixed bracket 1 at the end and passes through the hanger 2 .

[0043] In this embodiment, the fixed brackets 1 at both ends are T-shaped structures, and the fixed brackets 1 at the middle position are in the shape of a square; the two fixed brackets 1 are respectively connected to the two ends of the steel wire rope 3 to tension the steel wire rope 3. tight; the middle part of the steel wire rope 3 passes through each support hanger 2 successively,...

Embodiment 2

[0063] This embodiment provides a method for installing a lifeline for working at heights in a workshop, which is used to install the lifeline in Embodiment 1, including the following process

[0064] Set a fixed point every 40 to 60 meters, and each fixed point is respectively equipped with a fixed bracket 1 connected to the steel structure on the top of the workshop;

[0065] Set up a support point at intervals of 2 to 4 meters, and set up a support hanger 2 connected to the steel structure on the top of the workshop for each support point;

[0066] One end of the wire rope 3 is connected to the fixed bracket 1, and the other end passes through each hanger 2 in turn, and then connected to another fixed bracket 1;

[0067] The first limiting plate 241 and the second limiting plate 242 are locked, and the second limiting plate 242 cooperates with the damping device 8 to make the steel wire rope 3 bend, thereby tensioning the steel wire rope 3 .

[0068] In this embodiment, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com