Automobile overweight detection device for municipal bridge

A technology for detecting devices and bridges, applied in measuring devices, weighing equipment using fluid balance, special scales, etc. Fatigue, avoid the effect of inaccurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

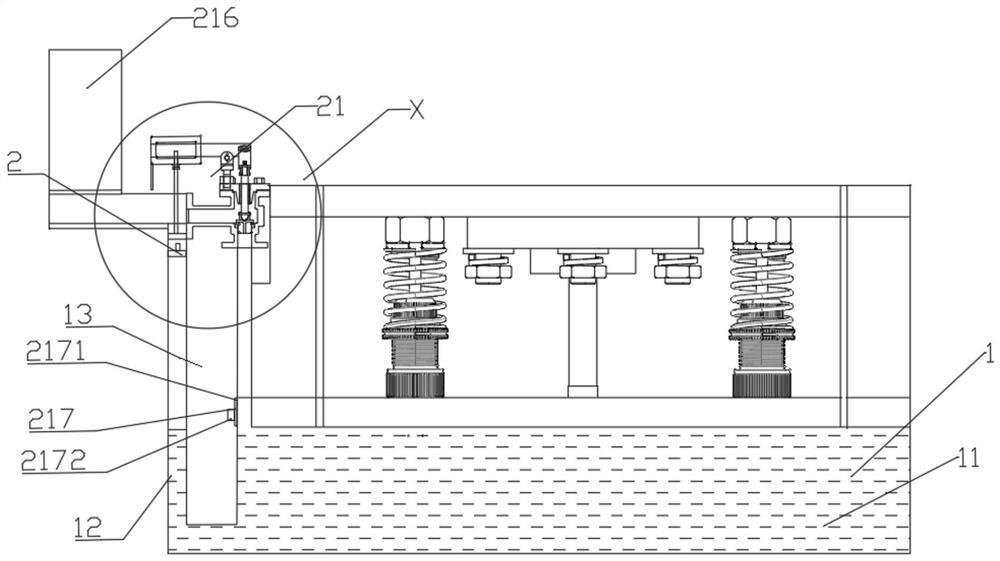

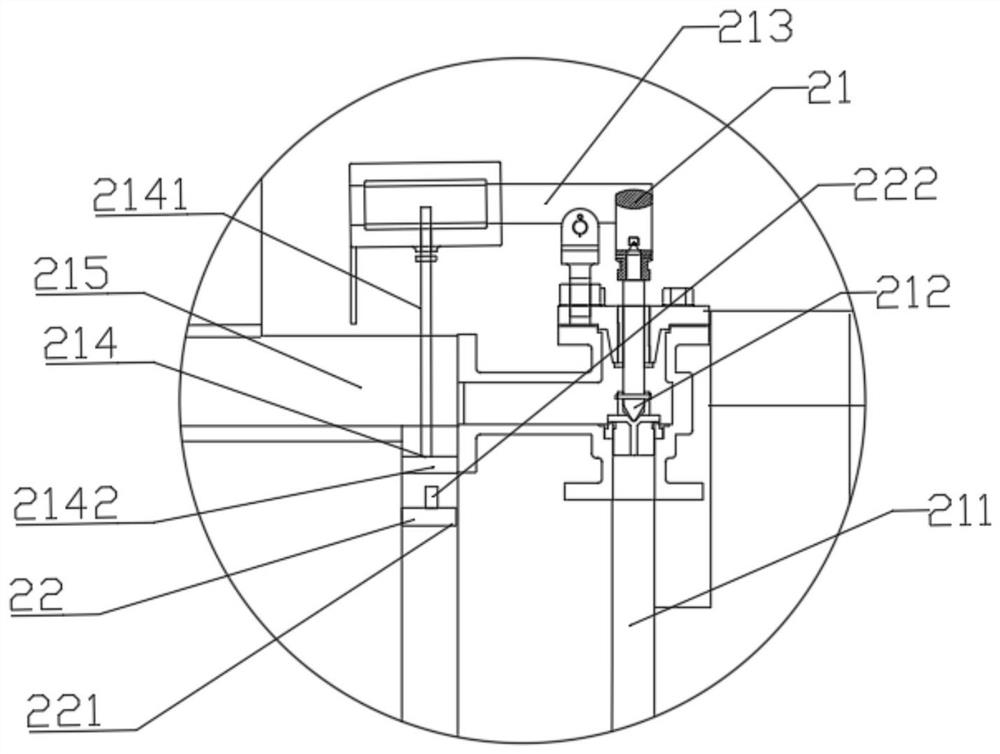

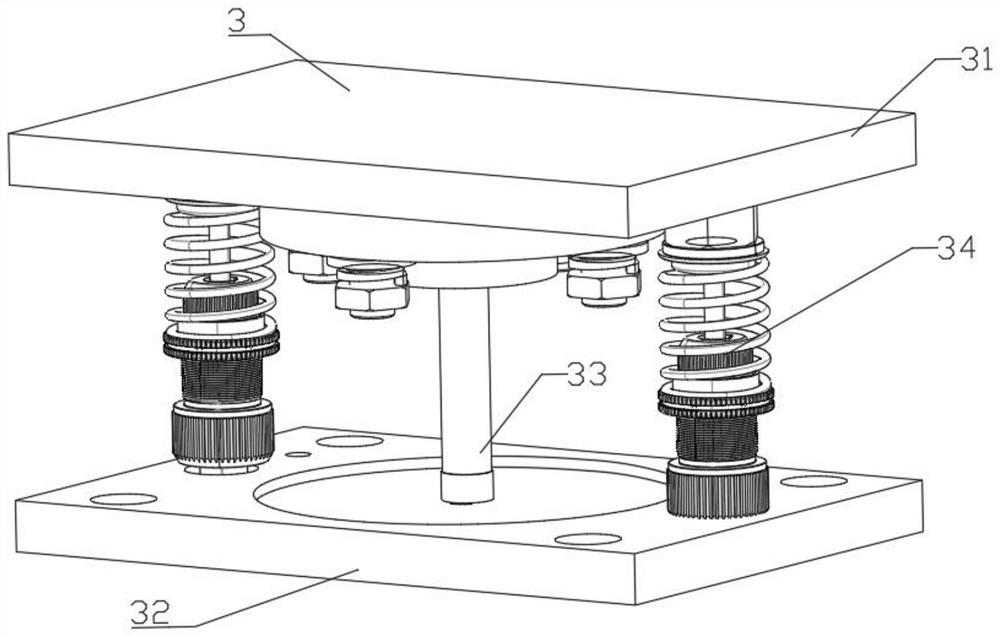

[0049] Such as Figure 1-6 As shown, a vehicle overweight detection device for municipal bridges includes a reservoir 1, a measuring mechanism 2, and a load-bearing mechanism 3. The measuring mechanism 2 is installed on the left side of the reservoir 1, and the load-bearing mechanism 3 is installed on the inside of the reservoir 1. In the half section, the load-bearing mechanism 3 includes a load-bearing upper plate 31, a load-bearing lower plate 32, a load-bearing cylinder 33, and a decompression spring 34. The bottom of the load-bearing upper plate 31 is fixedly connected to the top of the load-bearing cylinder 33, and the top of the load-bearing lower plate 32 is fixed to the bottom of the load-bearing cylinder 33. connection, there are two groups of decompression springs 34, and the two groups of decompression springs 34 are located on both sides of the load-bearing cylinder 33. The measuring mechanism 2 includes a liquid replenishment mechanism 21 and a measurement compone...

Embodiment 2

[0052] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, a vehicle overweight detection device for municipal bridges includes a reservoir 1, a measuring mechanism 2, and a load-bearing mechanism 3. The measuring mechanism 2 is installed on the left side of the reservoir 1, and the load-bearing mechanism 3 is installed on the inside of the reservoir 1. In the half section, the load-bearing mechanism 3 includes a load-bearing upper plate 31, a load-bearing lower plate 32, a load-bearing cylinder 33, and a decompression spring 34. The bottom of the load-bearing upper plate 31 is fixedly connected to the top of the load-bearing cylinder 33, and the top of the load-bearing lower plate 32 is fixed to the bottom of the load-bearing cylinder 33. connection, there are two groups of decompression springs 34, and the two groups of decompression springs 34 are located on both sides of the load-bearing cylinder 33. The measuring mechanism 2 i...

Embodiment 3

[0059] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, a vehicle overweight detection device for municipal bridges includes a reservoir 1, a measuring mechanism 2, and a load-bearing mechanism 3. The measuring mechanism 2 is installed on the left side of the reservoir 1, and the load-bearing mechanism 3 is installed on the inside of the reservoir 1. In the half section, the load-bearing mechanism 3 includes a load-bearing upper plate 31, a load-bearing lower plate 32, a load-bearing cylinder 33, and a decompression spring 34. The bottom of the load-bearing upper plate 31 is fixedly connected to the top of the load-bearing cylinder 33, and the top of the load-bearing lower plate 32 is fixed to the bottom of the load-bearing cylinder 33. connection, there are two groups of decompression springs 34, and the two groups of decompression springs 34 are located on both sides of the load-bearing cylinder 33. The measuring mechanism 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com