Camera lens group

A camera lens, lens technology, applied in optical components, instruments, optics, etc., can solve problems such as poor imaging quality, and achieve the effect of reducing noise and improving imaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

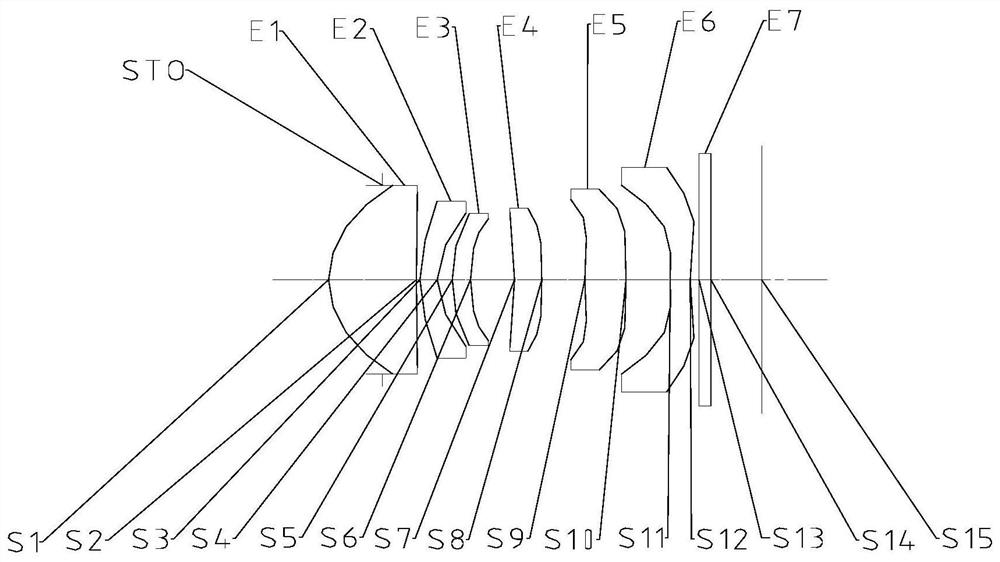

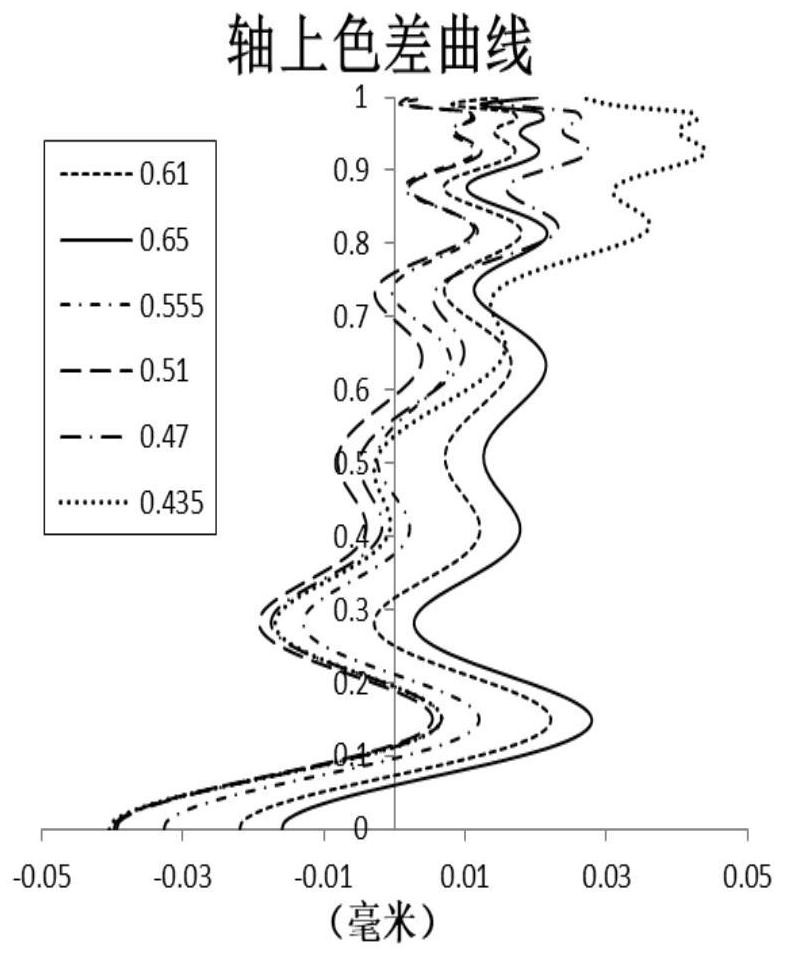

[0062] like Figure 1 to Figure 25 As shown, the imaging lens group includes the first lens E1, the second lens E2 with negative refractive power, the third lens E3, the fourth lens E4, and the fifth lens E4 with positive refractive power along the optical axis from the object side to the image side. For the lens E5 and the sixth lens E6, the object side S3 of the second lens is a convex surface, and the image side S4 of the second lens is a concave surface. The on-axis distance TTL from the object side of the first lens to the imaging surface, the half ImgH of the diagonal length of the effective pixel area on the imaging surface and the aperture value Fno of the imaging lens group satisfy: 3.5<TTL / ImgH*Fno<4; The half ImgH of the diagonal length of the effective pixel area on the imaging surface, the effective focal length f of the imaging lens group, and the maximum half field of view Semi-FOV of the imaging lens group meet: 4.6<f / ImgH / TAN(Semi-FOV) <5.3.

[0063] Prefera...

Embodiment 2

[0084] The imaging lens group includes first lens E1, second lens E2 with negative refractive power, third lens E3, fourth lens E4, fifth lens E5 with positive refractive power and In the sixth lens E6, the object side S5 of the second lens is convex, and the image side S6 of the second lens is concave. The effective focal length f of the imaging lens group, the axial distance BFL from the image side of the sixth lens to the imaging surface, and the aperture value Fno of the imaging lens group satisfy: 3<f / BFL / Fno<3.8; effective pixel area on the imaging surface Half of the diagonal length ImgH, the effective focal length f of the imaging lens group and the maximum semi-FOV of the imaging lens group satisfy: 4.6<f / ImgH / TAN(Semi-FOV)<5.3.

[0085] Preferably, 3.3

[0086] Preferably, 4.7

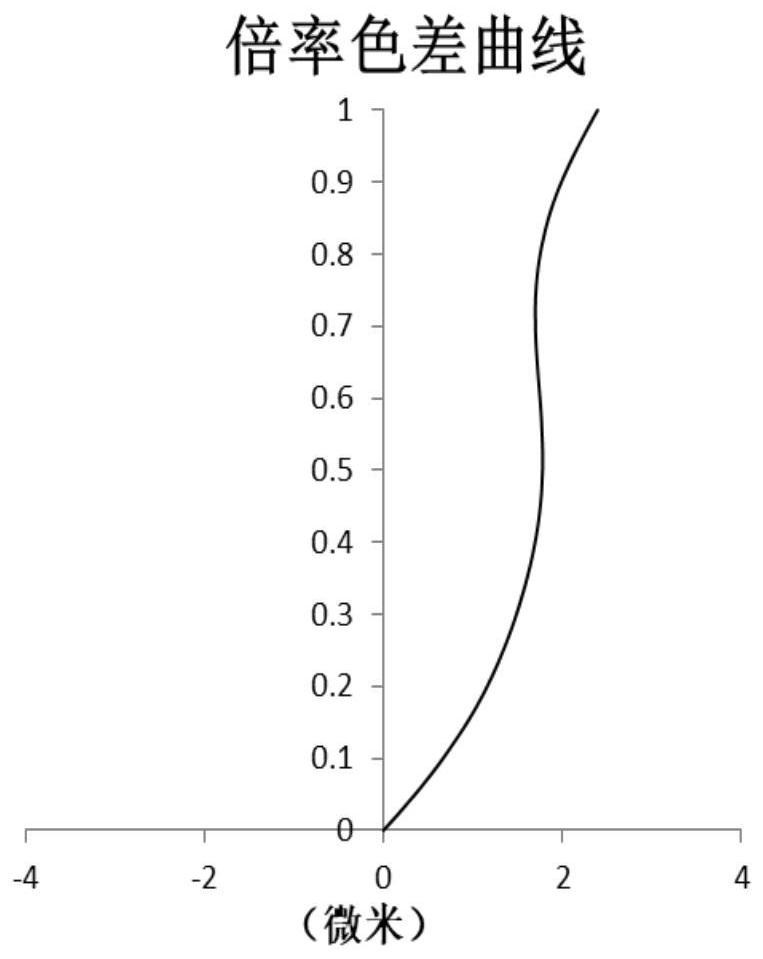

[0087] Through reasonable distribution of optical power, astigmatism and distortion can be effectively reduced, and the imaging quality of the camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com