A compressed air foam generating device and its application method

A technology of compressed air foam and generating device, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc. It can solve the problems that the quality and efficiency of fire extinguishing foam need to be further improved, and achieve the effect of convenient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

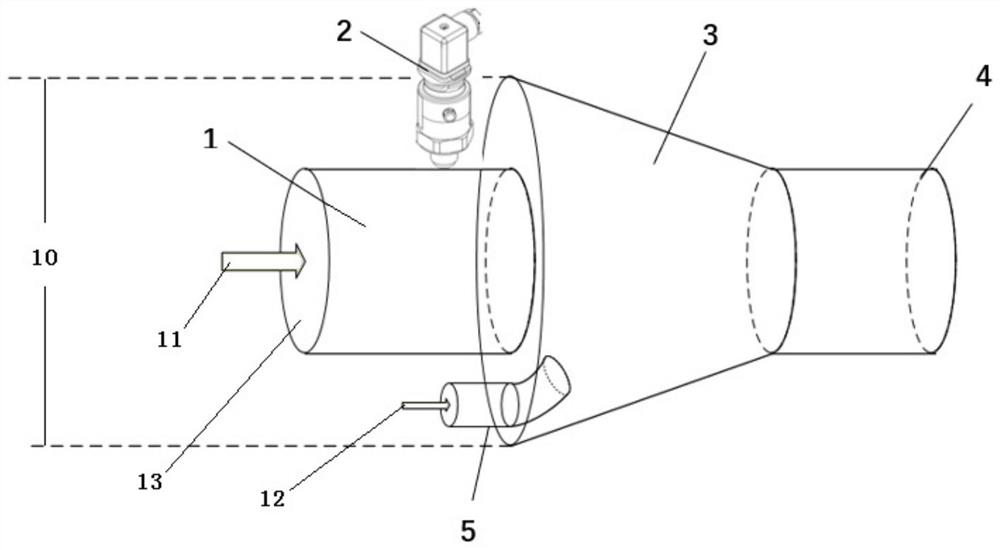

[0034] Such as figure 1 Shown is the basic graphic structure design of the foam mixing chamber 3. The foam mixture liquid inlet cylinder 1 is designed as a straight-through pipe of DN150. The raw material of the pipe can be changed according to different pressure and flow requirements. The entrance of the mixing chamber 3 is welded together by welding, and the outer wall contains a 1 / 2-inch hole for installing the pressure sensor 2. The foam mixing chamber 3 is a model of a conical shape with a large entrance and a small exit. The foam mixing The total length of the chamber 3 is 150mm, the taper of its circular table is 45°, the cross-section of the entrance is a circle with a diameter of 300mm, and an air inlet 5 with a diameter of 50mm is arranged on the underside, which is used for compressed air inlet, foam mixing chamber 3 The outlet cross section is a small circle with an inner diameter of 130mm and an outer diameter of 150mm. The spray cylinder 4 is connected to the ou...

Embodiment 2

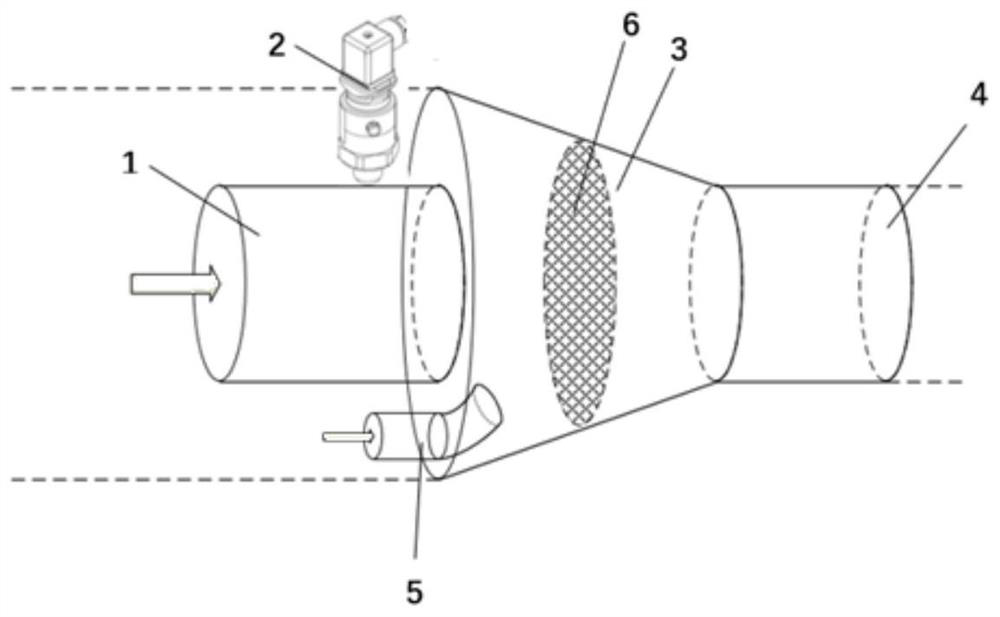

[0036] Such as figure 2 Shown is the design of adding a circular baffle plate with mesh 6 in the middle of the mixing chamber. The aperture of this circular mesh plate should be set to 1mm and its material should be related to the pressure and flow of mixing. The thickness of the board needs to be thick enough to withstand the required water pressure. The function of this mesh plate is to crush the large foam in the mixing chamber, so that the foam produced is more delicate and not easy to break, and has good fire extinguishing performance.

Embodiment 3

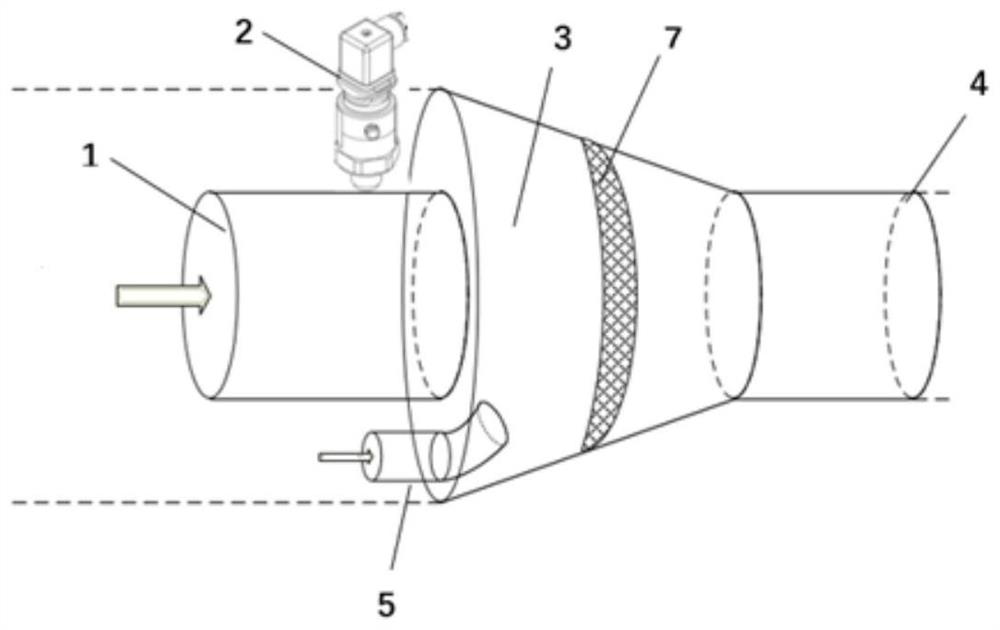

[0038] Such as image 3 As shown, a mesh arc-shaped baffle 7 is set in the middle of the foam mixing chamber. This setting is based on the structure of the foam mixing chamber 3. Because the inner wall of the foam mixing chamber 3 is slope-shaped, it should be fitted as much as possible when designing the baffle. The structure of the interface machinery, such equipment is generally more stable, not easy to damage and its tightness is better Figure II stronger. function with figure 2 same. Break the foam and improve the foam quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com