Continuously carbonating method and apparatus

A carbonization device and carbide technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as danger and prolong production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

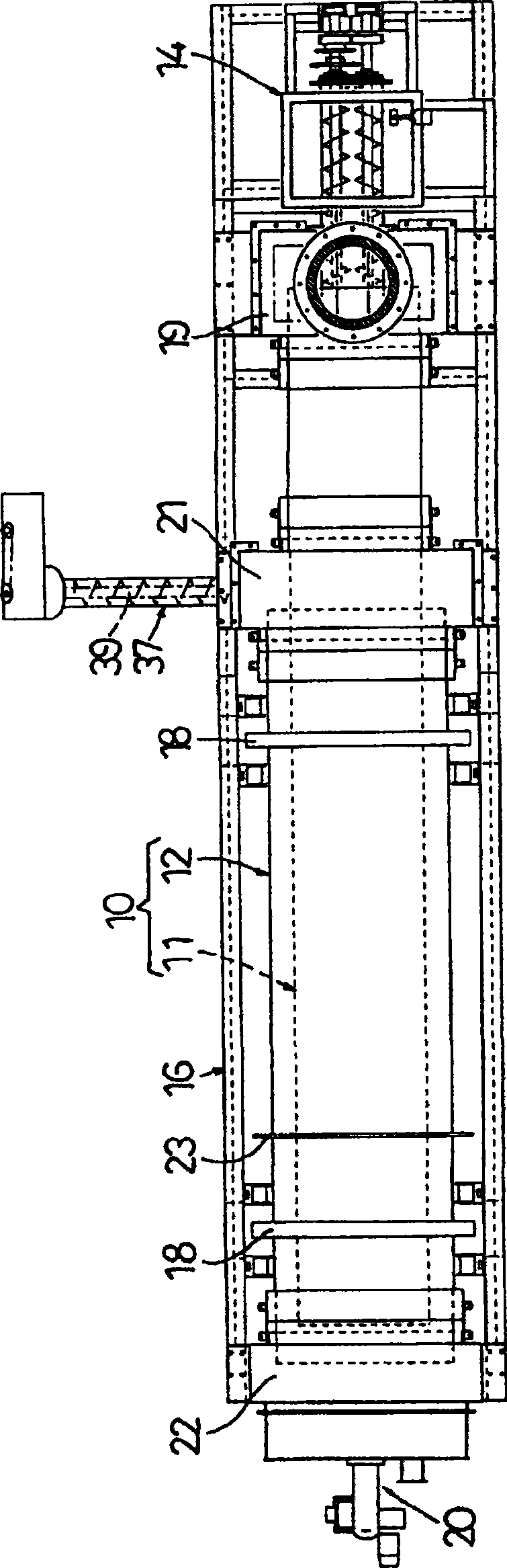

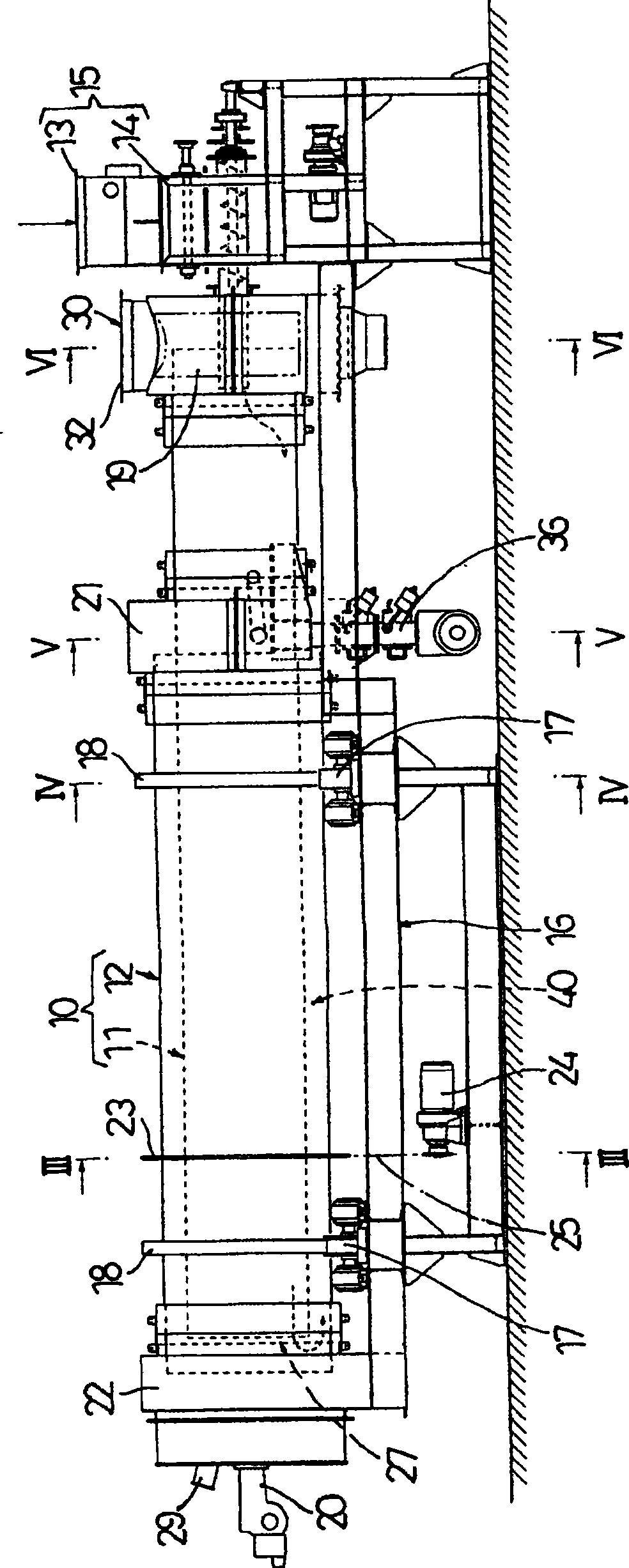

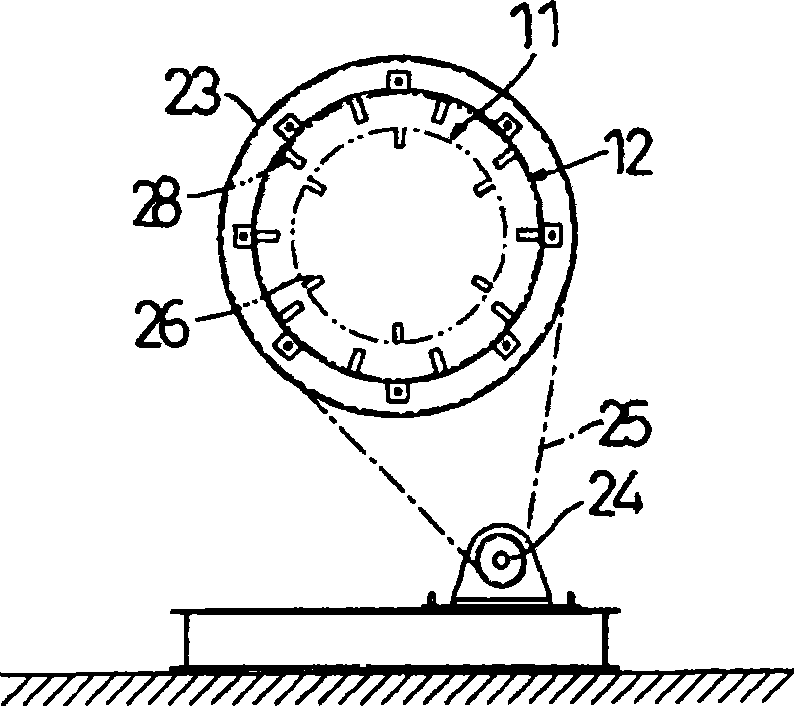

[0023] When carrying out the continuous carbonization method according to the present invention, the raw material composed of wood chips is moved along a substantially constant path from the inner cylinder constituting the rotary furnace to the outside of the rotary furnace via the outer cylinder. By supplying material into the inner cylinder and moving it from there to the outer cylinder, the dual cylinder structure of the inner cylinder and the outer cylinder is effectively utilized. That is, the raw material is combusted in the inner cylinder, and after the combustibles move to the outer cylinder, the supply of air between the inner and outer cylinders is cut off, and the combustion of the combusted substances is extinguished in the outer cylinder to generate carbides. While the carbides are moving in the outer cylinder, they are gradually cooled.

[0024] As a rotary furnace having a double drum structure, a rotary furnace capable of moving raw materials and combustion pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com