Dust removal and decontamination environment-friendly equipment for building and mine freight vehicles

A kind of environmental protection equipment and mining technology, which is applied in vehicle cleaning equipment, vehicle maintenance, vehicle cleaning, etc., can solve the problems of low efficiency and heavy labor, and achieve the effect of ensuring quality, reducing labor and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

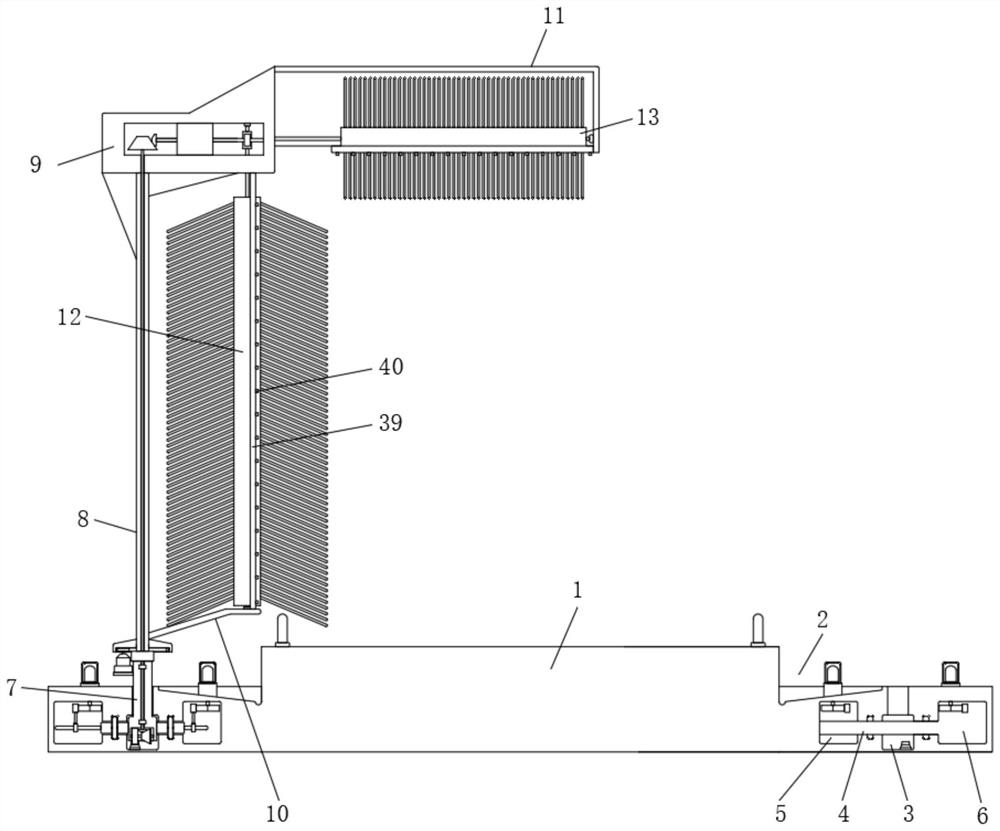

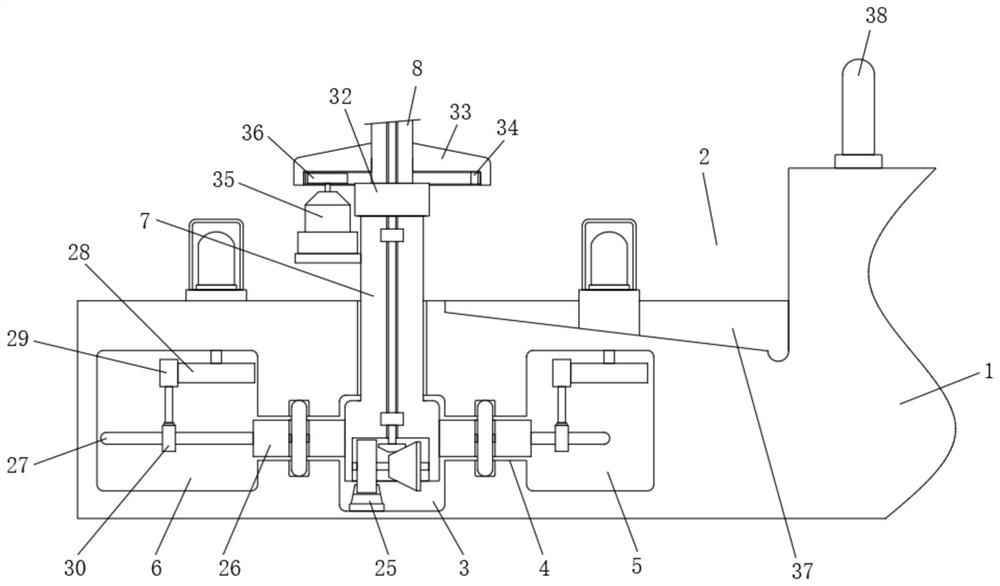

[0031] Embodiment one, by Figure 1 to Figure 5 Provided, the present invention comprises abutment 1, and the edge of abutment 1 top is provided with groove 2, and abutment 1 is flush with the ground, and when a vehicle needs to move to the top of abutment 1, can let When the vehicle is moving, a vertical ring groove 3 is provided in the middle of the groove 2, and a connecting ring groove 4 is provided on both sides of the middle part of the vertical ring groove 3, and a first inner ring groove is provided on the side where the two connecting ring grooves 4 are far away from each other. 5 and the second inner ring groove 6, the inside of the vertical ring groove 3 is equipped with a moving column 7, the top of the moving column 7 is equipped with a hollow rod 8, the top of the hollow rod 8 is equipped with a fixed box 9, and the bottom of the hollow rod 8 is installed with a Swash plate 10, cover 11 is installed on one end of fixed box 9, the first cleaning rolling brush 12 i...

Embodiment 2

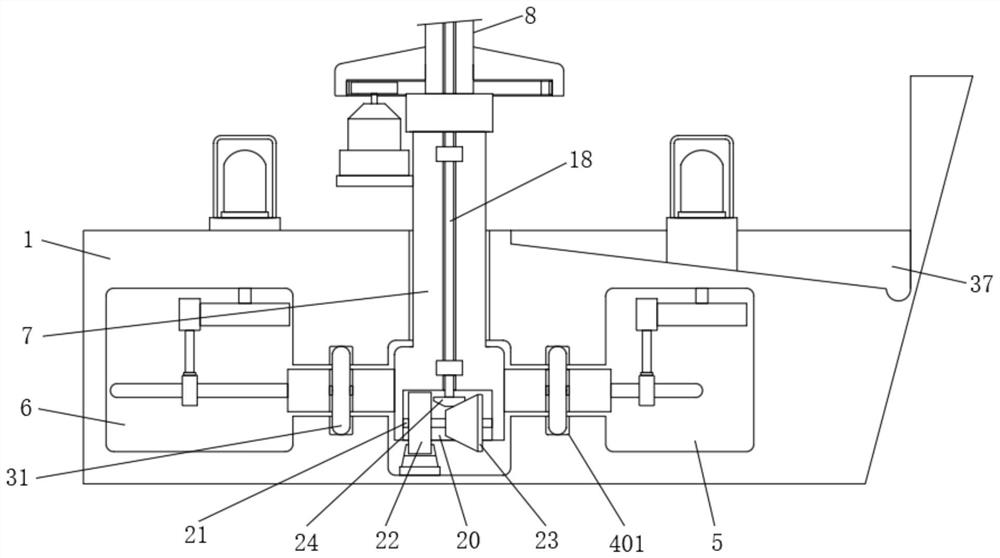

[0033] Embodiment two, on the basis of embodiment one, by image 3 Given, the bottom of the moving column 7 is provided with a mounting groove 20, the bottom of the mounting groove 20 is rotatably equipped with a rotating pin 21, and the both sides of the rotating pin 21 are respectively equipped with a transmission gear 22 and a second large bevel gear 23. The bottom extends to the inside of the mounting groove 20 and is fixedly installed with a second small bevel gear 24, the second small bevel gear 24 is meshed with the second large bevel gear 23, so that the transmission rod 18 can be effectively driven to rotate, and the transmission Rod 18 rotates and speeds up; the rotation of the second large bevel gear 23 drives the transmission rod 18 to rotate by the second small bevel gear 24, because the second large bevel gear 23 is greater than the second small bevel gear 24, the second large bevel gear 23 The rotation will cause the second bevel pinion 24 and the transmission r...

Embodiment 3

[0034] Embodiment three, on the basis of embodiment one, by figure 2 Given, a ring gear 25 is installed at the bottom of the vertical ring groove 3, and the ring gear 25 is meshed with the transmission gear 22, so that the movement of the moving column 7 can drive the transmission gear 22 to rotate, thereby providing power for the rotation of the transmission rod 18; When the moving column 7 is moving, the transmission gear 22 will drive the rotating pin 21 to rotate, and the rotation of the rotating pin 21 will drive the second large bevel gear 23 to rotate, and the rotation of the second large bevel gear 23 will pass through the second small bevel gear. 24 drives transmission rod 18 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com