Cleaning method of sampling clean bottle for oil inspection

A clean and oil-based technology, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as unqualified cleaning of sampling clean bottles, lowered oil inspection levels, and inaccurate inspections. Achieving good solvent chemical stability, saving cost and investment, and selecting reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

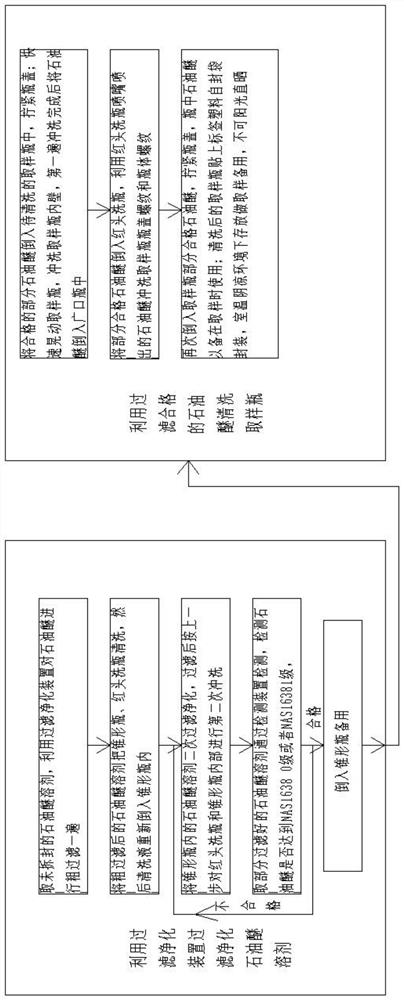

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, as figure 1 , image 3 , Figure 4 and Figure 5 As shown, the present invention is a method for cleaning a sampling clean bottle for oil inspection, comprising the following steps: 1. using a filtration and purification device to filter and purify the petroleum ether solvent; The clean bottle 11 is a PET transparent plastic round mouth square bottle. The inside of the bottle body is smooth and wrinkle-free, and the inside of the bottle body has no dead corners for cleaning. The bottle mouth is provided with a PP material sealing bottle cap; slot type. Capacity 250ml.

[0026] The concrete steps of step 1 are: S1, take unopened petroleum ether solvent, utilize filtration and purification device to carry out crude filtration to petroleum ether once; The conical flask 9 and the red-head washing bottle 10 are cleaned with the crudely filtered petroleum ether solvent, and then the cleaning solution is poured into the conical flask 9 again, S3, the petroleum ...

Embodiment 2

[0028] Example 2, on the basis of Example 1, the filter membrane used in the rough filtration in the step S1 in the step 1 is a specification 50mm*0.5um organic filter membrane 5, and the secondary filtration in the step S3 in the step 1 is used. The filter membrane used is an organic filter membrane 5 with a specification of 50mm*0.2um.

[0029] The detailed steps of step S2 in the step 1 are as follows: pour the crudely filtered petroleum ether part into the conical flask 9, cover the bottle, shake it up and down, left and right for no less than half a minute, and use petroleum ether to clean the conical flask. Inside the bottle 9; pour some petroleum ether into the red head washing bottle 10, screw on the bottle cap, shake it up and down, left and right for no less than half a minute, use petroleum ether to clean the inside of the red head washing bottle 10, and finally pour all the petroleum ether into the conical flask 9 in.

[0030]After the S3 step in the first step is...

Embodiment 3

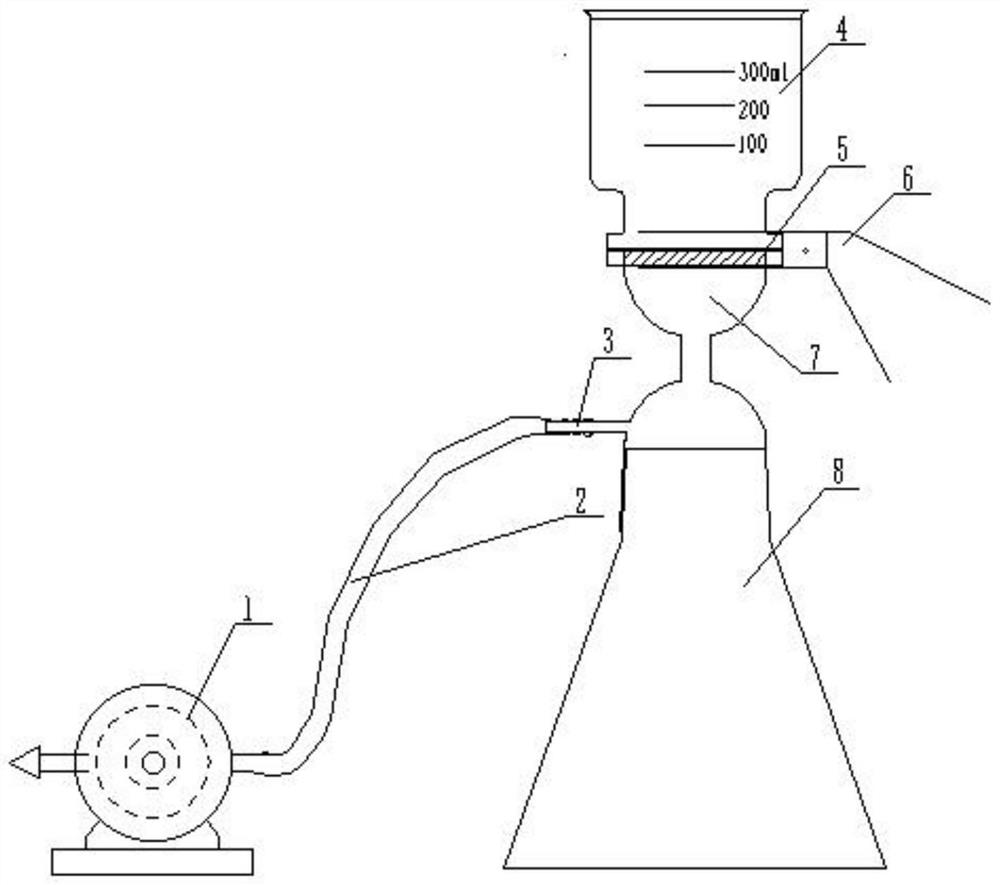

[0034] Example 3, as figure 2 As shown, the filtering and purifying device in Embodiment 1 or 2 includes a filter bottle 8, a sand core filter device 7 is connected above the filter bottle 8, an organic filter membrane 5 is provided above the sand core filter device 7, and the upper part of the sand core filter device 7 A clip 6 is connected, the upper part of the clip 6 is fixed with a sand core filter cup 4 , the lower part of the sand core filter device 7 is provided with an air suction port 3 , and the air suction port 3 is connected with a vacuum pump 1 . The filter bottle is 1000ml.

[0035] The top outer wall of the filter bottle 8 is installed in the bottom inner hole of the sand core filter device 7 in a frosted sealing fit, and this fit can form an airtight seal.

[0036] The air suction port 3 is connected with an air suction hose 2 , and the air suction hose 2 is connected with the vacuum pump 1 , and an anti-slip protrusion is provided on the outside of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com