A kind of water-based cleaning liquid and its preparation method and application

A water-based cleaning solution and detergent technology, applied in the cleaning field, can solve the problems of expensive equipment, many pipelines, and difficulty in cleaning and effective protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

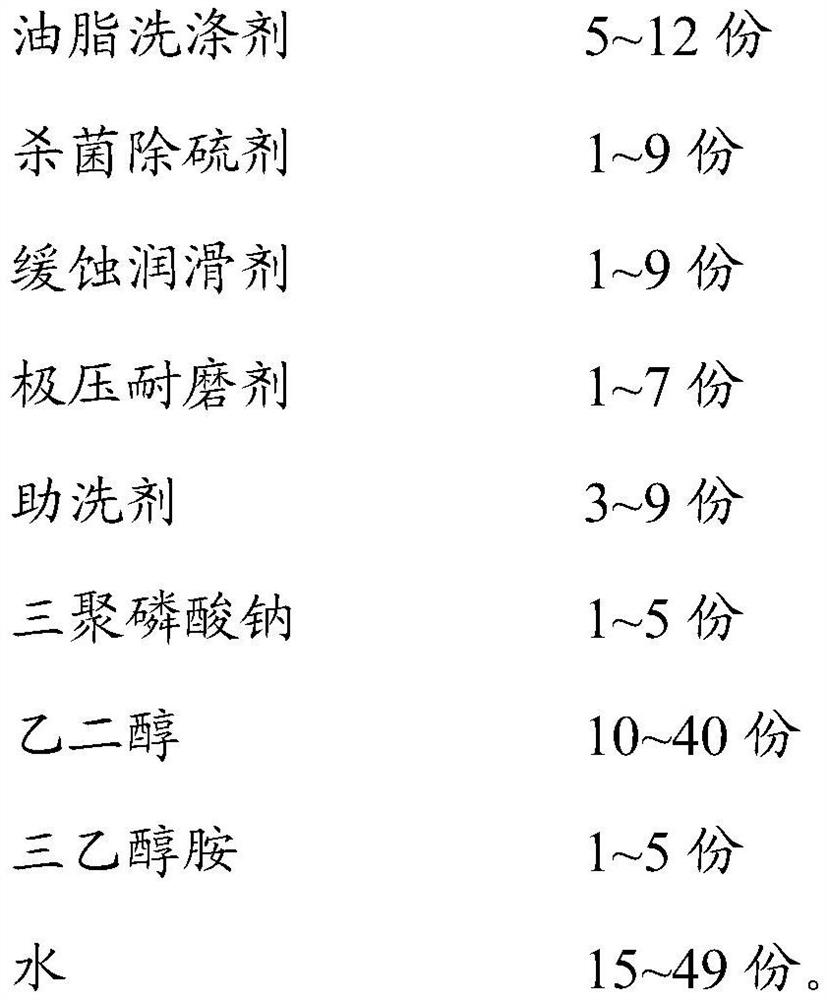

Embodiment 1

[0061] The water-based cleaning solution of the present embodiment consists of the following components: 5 parts by weight of grease detergent (butyl glucoside and cocamidopropyl betaine, weight ratio 1:1), 1 part by weight of oxazolidine, oleic acid 1 part by weight of diethanolamide, 1 part by weight of nano-lanthanum hexaboride modified by polyethylene glycol (the particle diameter is 5nm, the weight percentage of lanthanum contained is 0.5%, and the weight percentage of boron is 8.2%), 3 parts by weight of sodium citrate, 1 part by weight of sodium tripolyphosphate, 38 parts by weight of ethylene glycol, 1 part by weight of triethanolamine and 49 parts by weight of water.

[0062] Among them, polyethylene glycol-modified nano-lanthanum hexaboride is prepared by the following method: add 0.5g polyethylene glycol and 35mL distilled water into a 100mL three-necked flask, and mix well to obtain the first mixed solution; add 1gLaCl 3 ·6H 2 0, 0.05g tetramethylethylenediamine ...

Embodiment 2

[0065] The water-based cleaning solution of this embodiment is composed of the following components: 12 parts by weight of grease detergent (lauryl glucoside and cocamidopropyl betaine, weight ratio 9:1), 5-phenyl-2- 9 weight parts of oxazolidinones, 9 weight parts of coconut acid diethanolamides, polyacrylic acid-modified nano lanthanum tetraboride (particle diameter is 20nm, the weight percentage of the lanthanum that contains is 5.7%, the weight percentage of boron The content is 0.9%) 7 parts by weight, 9 parts by weight of sodium dihydrogen citrate, 5 parts by weight of sodium tripolyphosphate, 19 parts by weight of ethylene glycol, 5 parts by weight of triethanolamine and 15 parts by weight of water.

[0066] Wherein, the nano-lanthanum tetraboride modified by polyacrylic acid is prepared by the following method: add 1g polyacrylic acid and 35mL distilled water in a 100mL three-necked flask, and mix uniformly to obtain the first mixed solution; add 1gLa(NO 3 ) 3 , 0.12g...

Embodiment 3

[0069] The water-based cleaning solution of this embodiment is composed of the following components: 10 parts by weight of grease detergent (octyl glucoside and cocamidopropyl betaine, weight ratio 5:1), 3-methyl-2-oxazole 3 parts by weight of alkanone, 5 parts by weight of oleic acid diethanolamide borate, the nanometer lanthanum trifluoride (particle diameter is 10nm, the weight percentage of the lanthanum that contains is 1.5% of boron) that boric acid monoester tertiary amine modifies The weight percentage is 4.6%) 5 parts by weight, 4 parts by weight of sodium citrate, 3 parts by weight of sodium tripolyphosphate, 25 parts by weight of ethylene glycol, 4 parts by weight of triethanolamine and 41 parts by weight of water.

[0070] Among them, the nano-lanthanum trifluoride modified by boric acid monoester tertiary amine is prepared by the following method: add 2 g of boric acid monoester tertiary amine and 35 mL of distilled water into a 100 mL three-necked flask, and mix e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com